USER MANUAL

│

J1250

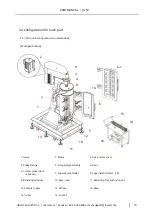

2.2 Technical Specifications - Control Unit

Functions

control unit

Specification

display screen

speed control

Max. RCF

ACC/DEC ramps

program memory

Time control

data transport

History tracking

Inverter control

Pump control

Safeties

Actual speed sensing

Door close/open sensing

Emergency Stop switch

foot switch

Level sensor 1, 2

Dimensions (W x D x H mm)

7” wide touch (Capacitive type)

1,000 to 15,000 RPM

15,801 xg (Radius: 62.814 mm)

3/4

99

< 100 hours

Yes (USB port)

Yes

3P4W 380V, 7.5KW

Selectable, auto or manual

Yes

Yes

Yes

Optional

Optional

405x 460 x 1310 (incl. warning light)

Weight

without cables

47 kg

HANIL Scientific Inc.

│

ihanil.com

│

Service: +82-2-3452-8966 / techsupport@ihanil.com

11