8

Standar

d and CR

HF (Grade)-

52-24

52-24-D

(2)

54-24

56-24

60-24

64-4F

68-4F

72-6F

76-6F

80-6F

84-8F

88-8F

92-10F

Connection

3” NPT

3” NPT

3” NPT

3” NPT

3” NPT

4” ANSI Flg.

4” ANSI Flg.

6” ANSI Flg.

6” ANSI Flg.

6” ANSI Flg.

8”ANSI Flg.

8”ANSI Flg.

10”ANSI Flg.

Maximum W

orking Pressure

300 psig

300 psig

225 psig

225 psig

225 psig

225 psig

225 psig

225 psig

225 psig

225 psig

225 psig

225 psig

225 psig

HF (Grade)-

52-80

52-80-D

(2)

54-80

56-80

60-80

64-100

68-100

72-150

76-150

80-150

84-200

88-200

92-250

Connection

DN 80 Flg.

DN 80 Flg.

DN 80 Flg.

DN 80 Flg.

DN 80 Flg.

DN 100 Flg.

DN 100 Flg.

DN 150 Flg.

DN 150 Flg.

DN 150 Flg.

DN 200 Flg.

DN 200 Flg.

DN 250 Flg.

Maximum W

orking Pressure

21.0 kgf/cm

2

21.0 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

High Pressure

HF (Grade)-

52-24-34

52-24-34-D

52-24-48

54-24-31

56-24-31

60-24-45

64-4F-30

68-4F-30

72-6F-24

76-6F-22

80-6F-22

84-8F-18

Connection

3” NPT

3” NPT

3” NPT

3” NPT

3” NPT

3” NPT

4” ANSI Flg.

4” ANSI Flg.

6” ANSI Flg.

6” ANSI Flg.

6” ANSI Flg.

8”ANSI Flg.

Maximum W

orking Pressure

500 psig

500 psig

700 psig

450 psig

450 psig

650 psig

440 psig

440 psig

360 psig

330 psig

330 psig

260 psig

HF (Grade)-

52-80-34

52-80-34-D

52-80-48

54-80-31

56-80-31

60-80-45

64-100-30

68-100-30

72-150-24

76-150-22

80-150-22

84-200-18

Connection

DN 80 Flg.

DN 80 Flg.

DN 80 Flg.

DN 80 Flg.

DN 80 Flg.

DN 80 Flg.

DN 100 Flg.

DN 100 Flg.

DN 150 Flg.

DN 150 Flg.

DN 150 Flg.

DN 200 Flg.

Maximum W

orking Pressure

35.0 kgf/cm

2

35.0 kgf/cm

2

49.0 kgf/cm

2

31.5 kgf/cm

2

31.5 kgf/cm

2

45.0 kgf/cm

2

30.8 kgf/cm

2

30.8 kgf/cm

2

25.2 kgf/cm

2

23.1 kgf/cm

2

23.1 kgf/cm

2

18.2 kgf/cm

2

No. of Elements E(Grade)-PV or PVS

1

1

1

2 (1)

2

3

4

5

8

11

14

19

26

34

Models

HP

HP

HP

HP

HP

HP

HP

HP

CF (Grade)-

52-24(5) 52-24-D(2) 52-80(5) 52-80-D(2)

52-24-34

52-24-34-D(2)

52-80-34

52-80-34-D(2)

52-24-48 52-80-48

54-24-31 54-80-31 56-24-31 56-80-31

54-24 54-80 56-24(5) 56-80(5)

60-24(5) 60-89(5)

60-24-45 60-80-45

64-4F(5) 64-100(5) 68-4F(5) 68-100(5)

64-4F-30 64-100-30 68-4F-30 68-100-30

72-6F 72-150

72-6F-24 72-150-24

76-6F 76-150 80-6F 80-150

76-6F-22 76-150-22 80-6F-22 80-150-22

84-8F 84-200

84-8F-18 84-200-18

88-8F 88-200

92-10F 92-250

Dimensions in (mm)

“A” w/thread

10.25 (260)

10.25 (260)

10.25 (260)

20.00 (508)

16.00 (406)

16.25 (413)

16.25 (413)

—

—

—

—

—

—

—

—

—

—

“A” w/flange

10.63 (270)

11.63 (295)

11.00 (279)

21.38 (543)

16.38 (416)

16.63 (423)

17.63 (448)

20.00 (508)

20.00 (508)

24.00 (610)

24.00 (610)

28.00 (711)

28.00 (711)

33.00 (838)

33.00 (838)

39.00 (991)

45.88 (1165)

“B”

40.88 (1038)

42.38 (1076)

40.44 (1027)

50.44 (1281)

48.00 (1219)

49.00 (1245)

55.50 (1410)

52.25 (1327)

55.50 (1410)

54.63 (1387)

55.88 (1419)

62.56 (1589)

63.88 (1622)

69.13 (1589)

66.25 (1683)

67.94 (1726)

70.94 (1802)

“C”

4.88 (124)

4.88 (124)

8.31 (211)

10.81 (275)

9.69 (246)

9.69 (246)

11.69 (297)

11.63 (295)

12.69 (322)

13.44 (341)

14.69 (373)

16.88 (429)

18.19 (462)

19.63 (498)

19.69 (500)

19.56 (497)

21.56 (548)

“D”

32.25 (819)

32.25 (819)

29.5 (749)

39.63 (1006)

38.31 (973)

39.31 (99)

40.50 (1029)

40.63 (1032)

40.56 (1030)

41.19 (1046)

39.44 (1002)

45.69 (1160)

43.44 (1103)

49.50 (1257)

44.31 (1126)

48.38 (1229)

49.38 (1254)

W

eight lb (kg)

w/thread

36 (16)

39 (17)

128 (58)

270 (123)

90 (41)

118 (54)

294 (133)

—

—

—

—

—

—

—

—

—

—

w/flange

52 (23)

65 (29)

154 (70)

296 (135)

106 (48)

134 (61)

320 (145)

(3)

(3)

271 (123)

524 (238)

(4)

(4)

709 (322)

980 (445)

918 (416)

1412 (640)

Drain Connection

1/2”

1/4”

3/4”

1”

1”

1”

1”

1”

1”

1”

1”

1”

1”

1”

1”

1”

1”

V

essel T

ype

I

I

II

III

IV

IV

III

IV

V

IV

V

IV

V

IV

V

IV

IV

NOTE: Dimensions and W

eights are for reference only

. Request certified drawings for construction purposes.

(

1)

E(Grade)-54

(2)

D signifies internal auto drain.

Add 1.5 in. (38mm) to dim. B and 3 lb (1.4 kg) to weight.

(3)

64-4F and 64-100: 178 (81);

68-4F and 68-100: 180 (82);

64-4F-30 and 64-100-30: 408 (183);

68-4F-30 and 68-100-30: 405 (184)

(4)

76-6F and 76-150: 518 (235);

80-6F and 80-150: 525 (238);

76-6F-22 and 76-150-22: 693 (314);

80-6F-22 and 80-150-22: 700 (318)

(5)

Includes Corrosion Resistant (CR) Models

Dimensions and Weights

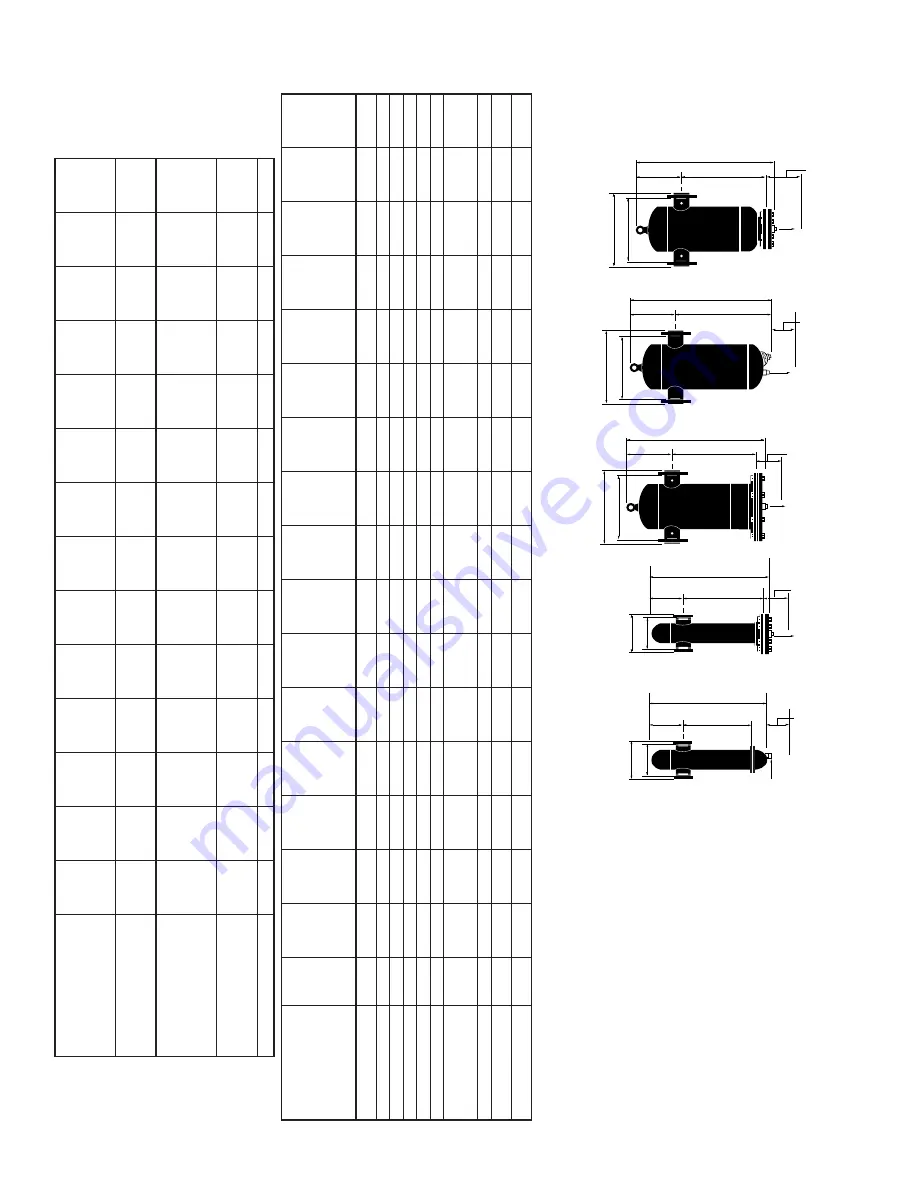

SERVICE CLEARANCE 24" (610mm)

DRAIN

D

B

C

A

TYPE II

SERVICE CLEARANCE 24" (610mm)

DRAIN

D

B

C

A

TYPE V

SERVICE CLEARANCE 24" (610mm)

DRAIN

D

B

C

A

TYPE IV

A w/Flg.

A

Optional Internal Auto Drain

SERVICE CLEARANCE 24" (610mm)

D

B

C

A w/Flg.

A

DRAIN

SERVICE CLEARANCE 24" (610mm)

D

B

C

A w/Flg.

A w/Flg.

A w/Flg.

TYPE I

TYPE III