5

2.0 Operation

Do not operate filter at pressures in ex

-

cess of Maximum Working Pressure indicated on Serial

Number Tag.

NOTE:

Maximum Operating Temperature - 150°F,

66°C. Liquid filtration above 120°F, 49°C is not recom

-

mended since there is typically oil present in a vapor

state which passes through the filter and condenses

downstream.

NOTE:

Grade 1 - If operated above 100°F, 38°C, a

Grade 1 filter may experience less than 1000 hours of

life because of greater oil vapor content.

A. Operational Checkpoints

Grades 11,9,7,6,5,3

1. Grades 9,7,6,5,3 - Check pressure drop across the

filter

a. Pressure differential in excess of 6 psi (0.42 kgf/

cm

2

) - pressure indicator in red area - indicates

that the filter sleeve or element should be

replaced.

NOTE:

Element should be changed annually or when

indicator changes to red, whichever occurs first.

NOTE:

Pressure drop should never exceed 15 psi

(1.0 kgf/cm

2

).

NOTE:

Grades 9, 7, 5, 3 - Pressure drop may temporar

-

ily increase when flow is resumed after flow stoppage.

Pressure drop should return to normal within one

hour.

b. Check for sudden reduction in pressure drop.

This might indicate:

(1) Possible leak across element o-ring seal

(2) Leak through the element due to physical

damage

2. Check flow, pressure, and temperature to make

certain filter is being operated within design

conditions.

3. Grades 11, 9, 7, 5, 3 - Check to see that filter is

installed level to insure proper drainage.

4. Grades 11, 9, 7, 5, 3 - Check that manual drains are

drained periodically or that automatic drains are

functioning.

Grade 1

1. Check for an oily smell by opening the manual

valve. If an oily smell exists, the following should

be checked:

a. Filter element adsorption capacity exhausted

b. Leak across element o-ring seal

c. Leak through element due to physical damage

d. Presence of liquids because of lack of or failure

of prefilters

e. Flow, pressure and temperatures outside de

-

sign conditions

f. Presence of gaseous impurities which cannot

be adsorbed by activated carbon

Methane, carbon monoxide, carbon di

-

oxide and various inorganic gases cannot be removed

by a Grade 1 filter.

C. Flow Capacity

Maximum air flow for the various filters at 100 psig

(7 kgf/cm

2

) is indicated in Table 1. To determine

maximum air flows at inlet pressures other than 100

psig (7 kgf/cm

2

), multiply flow from Table 1 by air flow

correction factor from Table 2 that corresponds to the

minimum operating pressure at the inlet of the filter.

NOTE:

Filters should not be selected by pipe size.

Select using flow rate and operating pressure only.

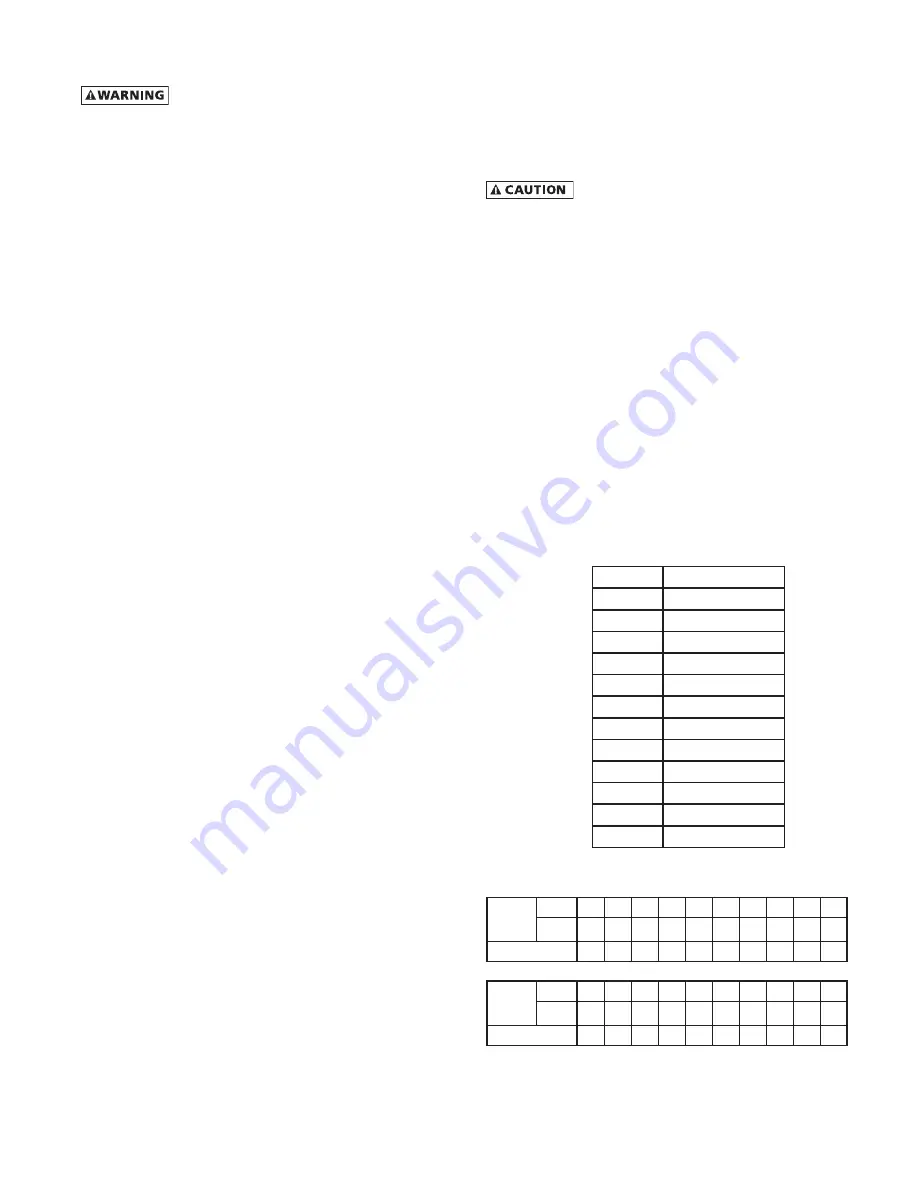

Table 1 - Maximum Flow @100 psig [7 kgf/cm

2

]

Housing

scfm

[m

3

/hr]

52

625

[1110]

54

1000

[1700]

56

1250

[2125]

60

1875

[3158]

64

2500

[4250]

68

3125

[5310]

72

5000

[8490]

76

6875

[11,670]

80

8750

[14,850]

84

11,875

[20,175]

88

16,250

[27,610]

92

21,250

[36,100]

Table 2 - Air Flow Correction Factor

Maximum

Inlet

Pressure

psig

20

30

40

60

80 100 125 150 175 200

kgf/cm

2

1.4 2.1 2.8 4.2 5.6 7.0 8.8 10.6 12.3 14.1

Correction Factor

0.30 0.39 0.48 0.65 0.82 1.00 1.22 1.43 1.65 1.87

Maximum

Inlet

Pressure

psig

250 300 350 400 450 500 550 600 650 700

kgf/cm

2

17.6 21.1 24.6 28.1 31.6 35.2 38.7 42.2 45.7 49.2

Correction Factor

2.31 2.74 3.18 3.62 4.05 4.49 4.92 5.36 5.80 6.23