6

3.0 Maintenance

A. When to Replace Filter Element

NOTE:

Grades 7,6,5,3,1 - complete element is re

-

placed; Grade 9 - unless separator core is damaged

outer sleeve only is replaced.

1. Grades 6 (dry desiccant afterfilter)

Initial drop: 1 psi (0.07 kgf/cm

2

). Pressure drop

increases as element loads with solid particles. Re

-

place when pressure drop reaches 10 psi (0.7 kgf/

cm

2

) (indicator in red area) or annually, whichever

occurs first.

2. Grade 11 (mechanical separator)

Element should not require replacement unless

physically damaged. If sludge accumulates, ele

-

ment can be removed and cleaned with soap and

water.

3. Grades 9, 7, 5, 3 (coalescing filters)

a. Initial (dry) pressure drop: 1 psi (0.07 kgf/cm

2

)

to 2 psi (0.14 kgf/cm

2

)

b. Operating pressure drop: As filter becomes liq

-

uid loaded (wetted), pressure drop will increase

to 2 to 6 psi (0.14 to 0.42 kgf/cm

2

). Further

pressure drop occurs as element loads with

solid particles.

FOR MAXIMUM FILTRATION EFFICIENCY, REPLACE

ELEMENT WHEN PRESSURE DROP REACHES 6 PSI (0.42

KGF/CM

2

) (INDICATOR IN RED AREA) OR ANNUALLY,

WHICHEVER OCCURS FIRST.

NOTE:

Pressure drop may temporarily increase when

flow is resumed after flow stoppage. Pressure drop

should return to normal within one hour.

NOTE:

Grades 5 and 3 - During normal operation

bottom of foam sleeve will have a band of oil.

Spotting above the band indicates that liquids are

accumulating faster than they can be drained and that

prefiltration is required.

4. Grade 1 (activated carbon filters)

a. Adsorption capacity - 1000 hours at rated

capacity. Element life is exhausted when odor

can be detected downstream of the filter.

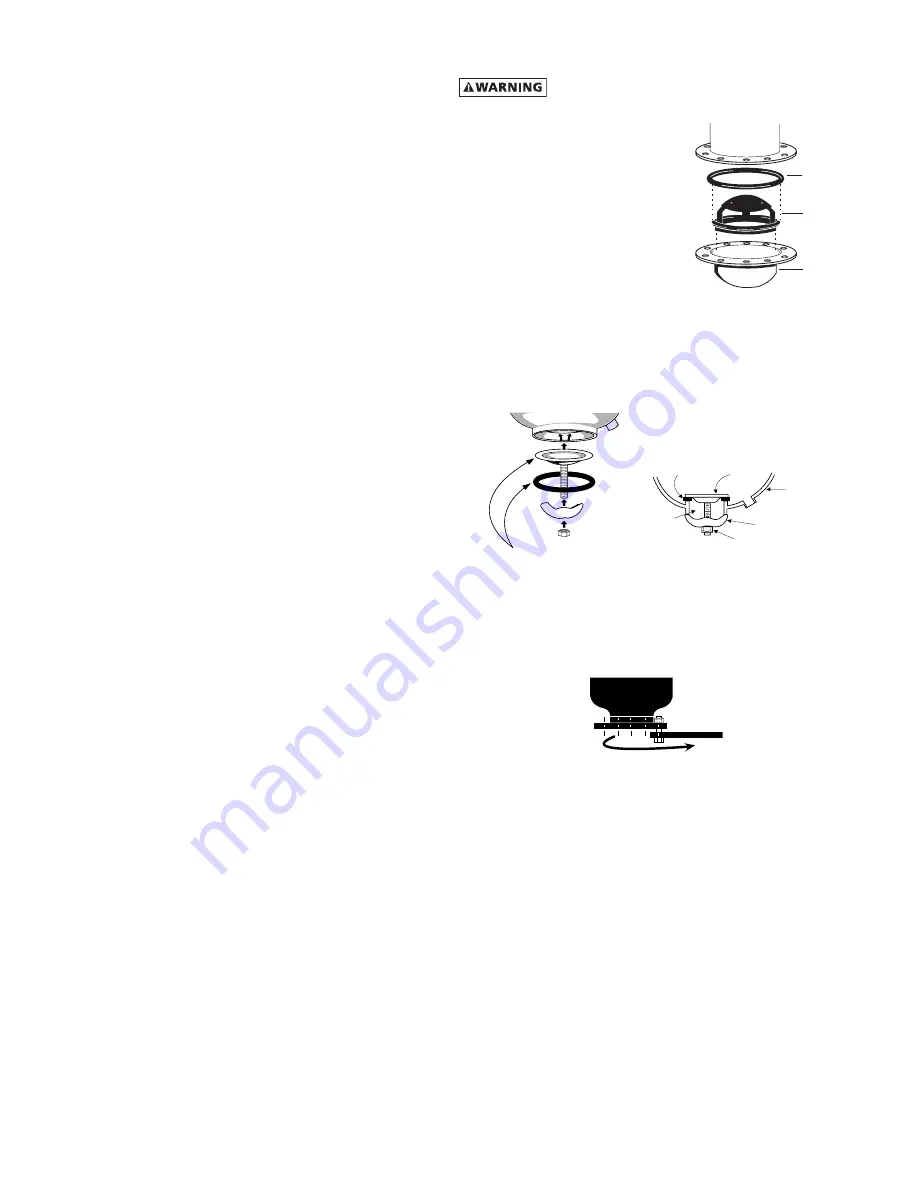

SEAL PLATE

VESSEL

YOKE

NUT

GASKET

TILT THE SEAL PLATE

AND GASKET TO FIT IN OPENING

HAND HOLE

Handhole

O-RING

PLASTIC

SEAL RING

RETAINER

LOWER

BOTTOM

OF SHELL

Model 52

B. Procedure for Element Replacement

THIS FILTER IS A PRESSURE CONTAINING

DEVICE. DEPRESSURIZE BEFORE SERVICING.

1. By-pass the filter to permit

servicing.

2. Depressurize the filter as

-

sembly slowly by opening

blowdown valve.

3. Open pressure vessel

3A. Model 52 - Remove flange

bolts. Lower bottom

shell, o-ring, and seal ring

retainer.

3B. Models with handhole

a. Remove nut and yoke

b. Lift seal plate and turn so that seal plate and

seal plate gasket can be removed.

3C. Models with flanged bottom

a. Loosen bottom blind flange bolts.

b. Remove all but one bolt.

c. Swing flange to one side.

Bottom Flange

4. Starting in the center, unscrew the filter elements

and remove the filter elements and element o-

rings.