7

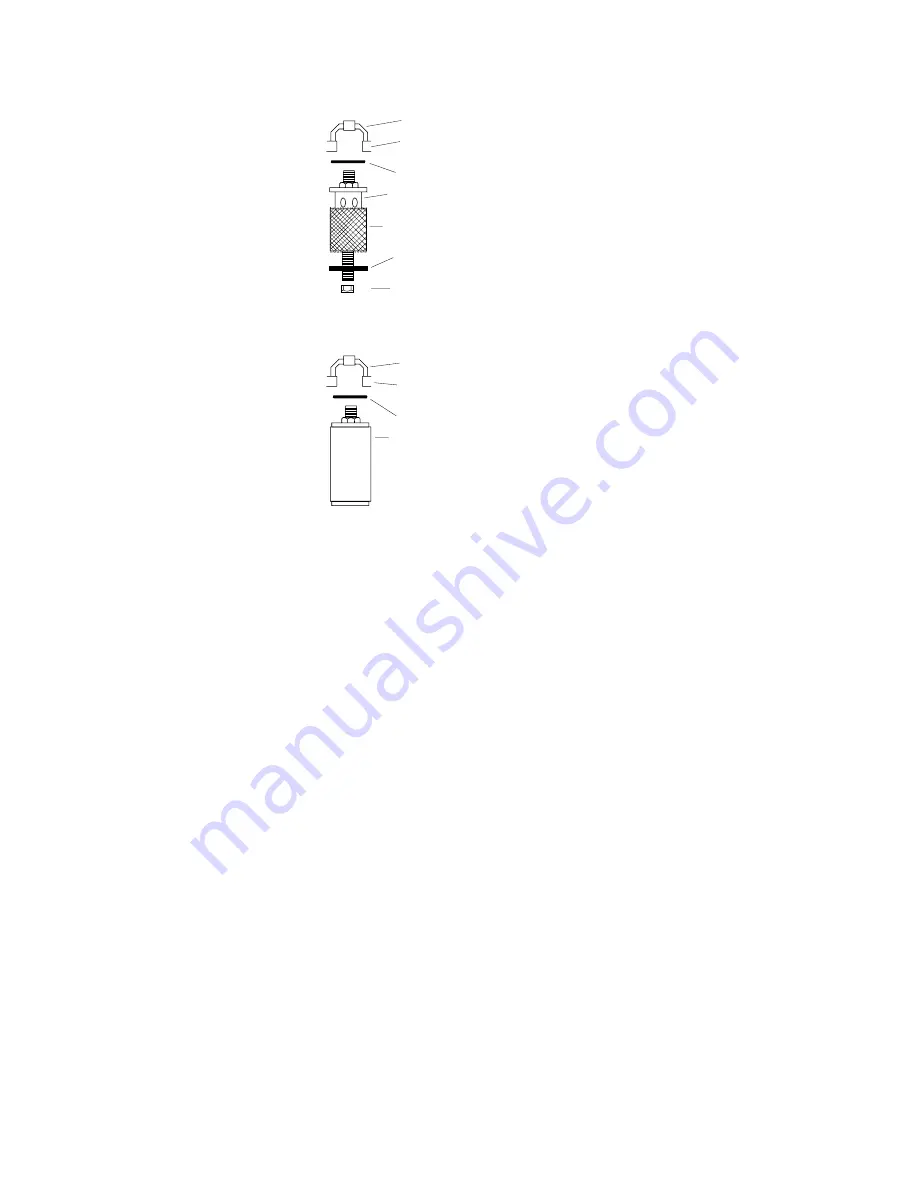

5. Grades 7, 6, 5, 3, 1 - Discard old elements and o-

rings.

5A. Grade 9

a. Remove nylon nut and

bottom cap

b. Slide disposable filter

sleeve down over sepa

-

rator core.

c. If necessary, clean sepa

-

rator core with soap and

water.

d. Slide new filter sleeve

over separator core and

replace bottom cap and

nylon nut.

6. Clean face of inlet manifold

with a mild detergent us

-

ing a long-handled brush

or clean rag attached to a

rod. Manifold face must be

free of all dirt and grease

to insure proper o-ring seal

between new filter element

top cap and inlet manifold.

7. Install new o-rings in the

o-ring grooves in each filter

element top cap.

8. Starting from the outside (filter element closest

to the vessel wall), screw new filter elements into

inlet manifold connections. A cone in the mani

-

fold will guide the element bolt into the female

threads.

NOTE:

Grades 5, 3 and 1 - Do not handle elements by

outside foam cover. Handle by plastic packaging and

bottom end cap only.

NOTE:

It is only necessary to finger tighten the filter

element to insure a seal.

DO NOT WRENCH TIGHTEN

9. Close vessel

9A. Model 52 - Reassemble bottom shell, o-ring and

seal-ring retainer to housing. Make sure seal-ring

retainer provides a backup for the o-ring as shown

in drawing.

9B. Models with hand hole

a. Reinsert seal plate and seal plate gasket into

vessel and position on lip as shown in drawing.

NOTE:

Do not reuse gasket if gasket is torn or gasket

surface is damaged.

b. Reinstall yoke and nut.

c. Tighten nut making sure that gasket is properly

positioned under seal plate.

CONE

INLET

MANIFOLD

O-RING

SEPARATOR

CORE

REPLACEMENT

SLEEVE

BOTTOM

CAP

NUT

CONE

INLET

MANIFOLD

O-RING

CARTRIDGE

Grade 9 -

Sleeve Replacement

All Grades -

Element Replacement

9C. Models with flanged bottom

a. Swing blind bottom flange into position.

b. Rebolt after inspecting flange gasket to ensure

its integrity.

10. Pressurize unit slowly by slowly opening inlet

valve, then opening outlet valve, and finally clos

-

ing by-pass valve.