37

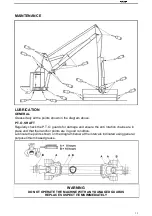

HYDRAULIC HOSES

The condition of all hoses should be carefully checked during routine service of the

machine. Hoses that have been chaffed or damaged on their outer casing should be

securely wrapped with waterproof adhesive tape to stop the metal braid from rusting.

Hoses that have suffered damage to the metal braid should be changed at the

earliest opportunity.

HOSE REPLACEMENT

Replace one hose at a time to avoid the risk of wrong connections.

When the hose is screwed to an additional fitting or union, use a second spanner

on the union to avoid breaking both seals.

Do not use jointing compound on the threads.

Avoid twisting the hose. Adjust the hose line to ensure freedom from rubbing

or trapping before tightening hose end connections.

Before changing hoses study the installation these are carefully calculated to prevent hose

damage during operation. Always replace hoses in exactly the same manner. This is

especially important for the flail hoses where they must be crossed, upper to lower, at the

dipper and head pivots.

SAFETY NOTE

Soft Seal hose connections are capable of holding pressure when the nut is only ‘finger

tight’. It is therefore recommended that when dismantling, the hose be manually flexed, to

relieve any residual pressure, with the retaining nut slackened prior to complete

disassembly.