45

EVENT MANAGEMENT

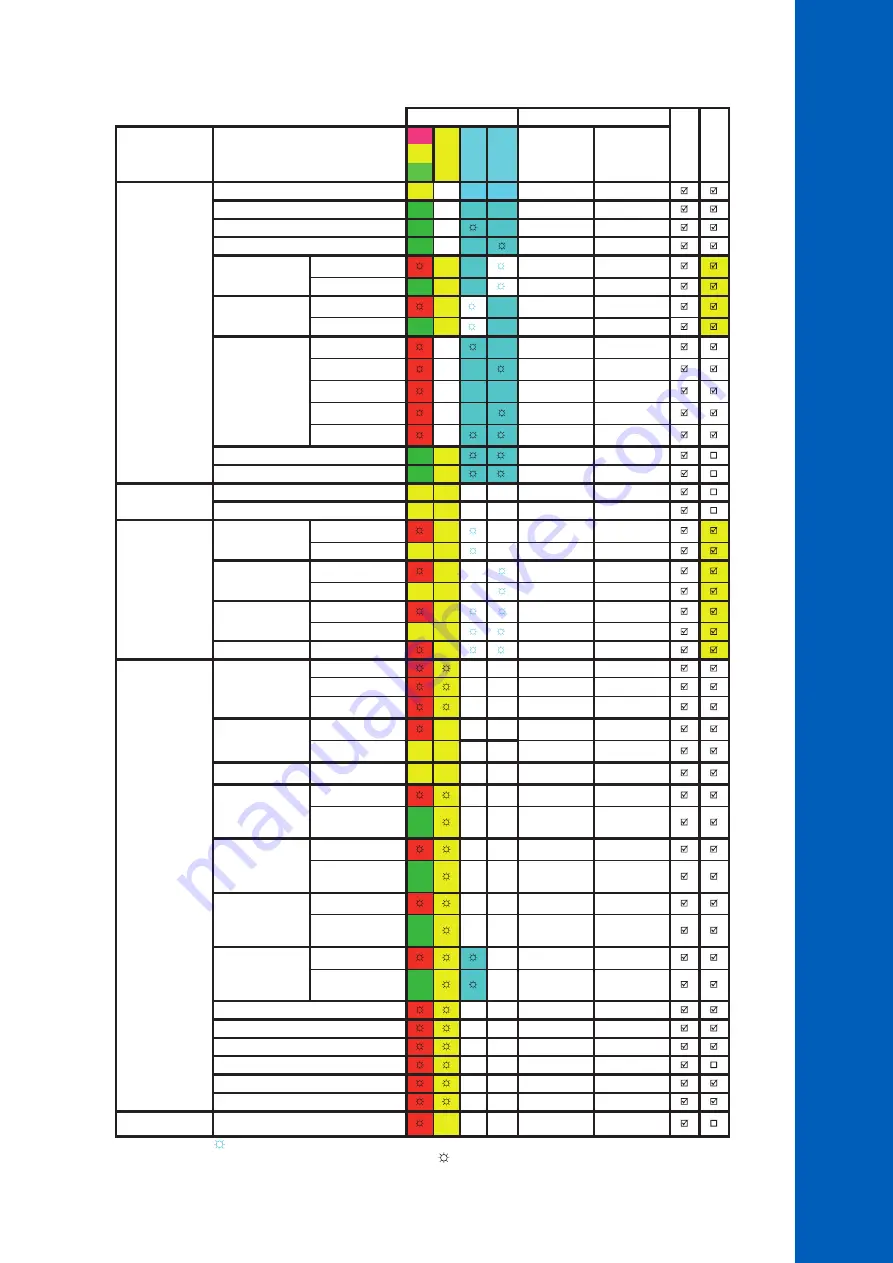

The table describes LEDs status, dosing pumps, measurement and logging processes for different controller modes.

LEDs

Dosing pumps

Measure

Logging

Modes

Events

SERVICE

pH

pH

RUN

With dosing delay at start-up

Off

Off

No dosing

Auto-Off

Auto-Off

Dosing Acid

Auto-On

Auto-Off

Dosing Chlorine

Auto-Off

Auto-On

Manual Off/On

No active alarms

Manual Off/On

Pump pH Manual

Manual Off/On

No active alarms

Manual Off/On

Warnings

Auto-On

Off

( )

Auto-Off

On

Auto-Off

On

Auto-Off

On

( )

( )

Auto

Auto

No logging (no alarms)

( )

( )

Auto

Auto

No cloud connectivity (no alarms)

( )

( )

Auto

Auto

HOLD

Run pH or ORP user calibration

Off

Off

Change settings ( SETUP)

Off

Off

MANUAL

Pump Acid On

Manual-On

Manual-Off

No active alarms

Manual-On

Manual-Off

Manual-Off

Manual-On

No active alarms

Manual-Off

Manual-On

Both On

Manual-On

Manual-On

No active alarms

Manual-On

Manual-On

No probe

---

( )

( )

Manual

Manual

Alarm

High or Low pH

Auto-Off

Auto-Off

High or Low ORP

Auto-Off

Auto-Off

Auto-Off

Auto-Off

Hold In

Auto-Off

Auto-Off

Auto-Off

Auto-Off

Remote Hold

Auto-Off

Auto-Off

Overtime pH

Auto-Off

Auto-Off

Auto-Off

Auto-Off

Auto-Off

Auto-Off

Auto-Off

Auto-Off

Auto-Off

Auto-Off

Auto-Off

Auto-Off

( )

Auto

Auto-Off

( )

Auto

Auto-Off

pH Under/Over range

Auto-Off

Auto-Off

ORP Under/Over range

Auto-Off

Auto-Off

Temp Under/Over range

Auto-Off

Auto-Off

No probe

Auto-Off

Auto-Off

No Factory Calibration

Auto-Off

Auto-Off

No User Calibration

Auto-Off

Auto-Off

SYSYEM ERROR

Off

Off

( )-depending on pH-ORP regulators status

Cl

2

Cl

2

Pump Cl

2

Manual

High or Low alarms

active

Auto-

Wait

Auto-

Wait

High or Low alarms

active

Auto-

Wait

Auto-

Wait

High pH warning

active

Low pH warning

active

High ORP warning

active

Low ORP warning

active

High or Low

Temperature active

High or Low alarms

active

Pump Cl

2

On

High or Low alarms

active

High or Low alarms

active

ALARMS &

PROCESS ERRORS

High or Low

Temperature

High/Low warning or

alarm active

No High/Low warning

or alarm active

Hold mode remotely

activated

High / Low warning

or alarm active

No High/Low

warnings, No alarms

active

Overtime Cl

2

High / Low warning

or alarm active

No High/Low

warnings, No alarms

active

Low Level Acid

tank

High / Low warning

or alarm active

No High/Low

warnings, No alarms

active

Low Level Cl

2

tank

High / Low warning

or alarm active

No High/Low

warnings, No alarms

active

Critical hardware errors (power, internal

temperature, I

2

C)

-blinking when Manual-On, off when

Manual Off

ST

ATUS