27

26

•

Make sure that the rubber O-ring sits

properly inside the membrane cap.

•

With the sensor facing down, slowly

screw the membrane cap clockwise.

Some electrolyte will overflow.

The platinum cathode should always be

bright and untarnished.

If it is tarnished or stained, which could be

due to contact with certain gases or ex-

tended use with a loose or damaged mem-

brane, the cathode should be cleaned. Use

a clean lint-free cardboard or cloth. Rub

the cathode very gently side to side 4-5

times. This will be enough to polish and

remove any stains without damaging the

platinum tip.

Afterwards, rinse the probe with deionized

or distilled water, and install a new mem-

brane cap using fresh electrolyte and fol-

low the above procedure.

Re-calibrate the instrument.

Important: For accurate and stable mea-

surements, it is important that the surface

of the membrane is in perfect condition.

This semipermeable membrane isolates the

sensor elements from the environment but

allows oxygen to enter. If any dirt is ob-

served on the membrane, rinse carefully

with distilled or deionized water. If any

imperfection still exists, or any damage is

evident (such as wrinkles or tears-holes),

the membrane should be replaced.

Make sure that the O-Ring sits properly in

the membrane cap.

PROBE & MEMBRANE MAINTENANCE

The DO probe body is made of reinforced

plastic for maximum durability.

A built-in thermistor temperature sensor pro-

vides temperature measurements. It is al-

ways recommended to keep the protective

cap on the probe when it is not used, to

provide protection against damage and dirt.

To replace the membrane or refill with

electrolyte, proceed as follows:

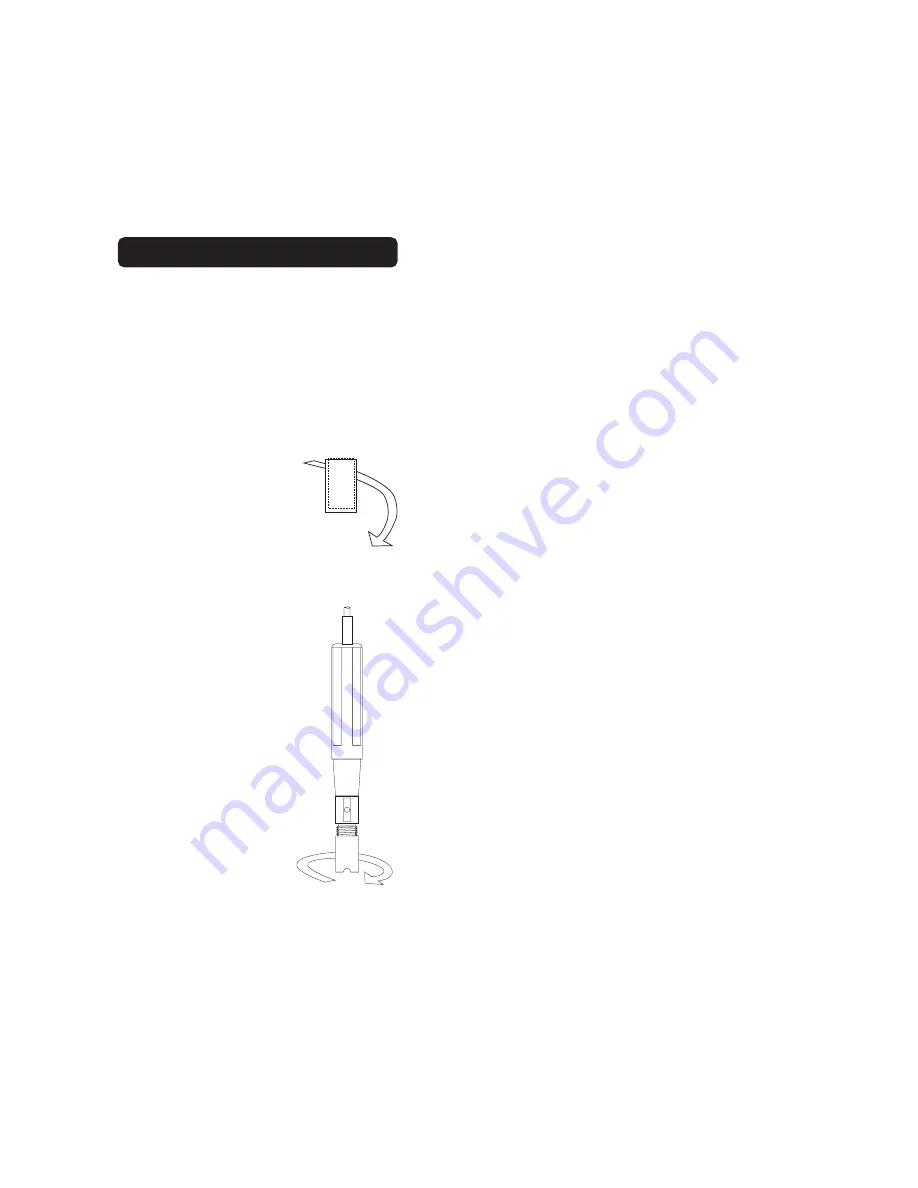

•

Remove the protective

cap by gently twisting

and pulling it off the

probe body (fig.1).

•

Unscrew the membrane

cap by turning it coun-

terclockwise (fig.2).

•

Wet the sensor by

soaking the bottom (2.5

cm / 1") of the probe

in HI 7041S electrolyte

for 5 minutes.

•

Rinse the new mem-

brane (HI 76407A, sup-

plied with the meter)

with electrolyte solution

while shaking it gen-

tly. Refill with fresh

electrolyte solution.

•

Gently tap the sides of

the membrane cap with

your finger to ensure

that no air bubbles re-

main trapped. Do no di-

rectly tap the bottom

with your finger as this

will damage the mem-

brane.

TWIST

AND

PULL

fig. 1

UNSCREW

fig. 2