18

SENSOR PREP

ARA

TION / ACTIV

ATION

pH Preparation

Remove the shipping cap from the pH sensor. If the shipping cap does not contain any liquid, pour

HI70300

into shipping cap, place it back on the sensor and soak for at least 1/2 hour before use. If

HI70300

is not available, pH 4.01 buffer may be substituted.

ORP Activation

For improved redox measurements, the surface of the sensor must be clean and smooth. A

pretreatment procedure should be performed to ensure quick response.

The pretreatment of the sensor is determined by the pH and the ORP potential values of the sample.

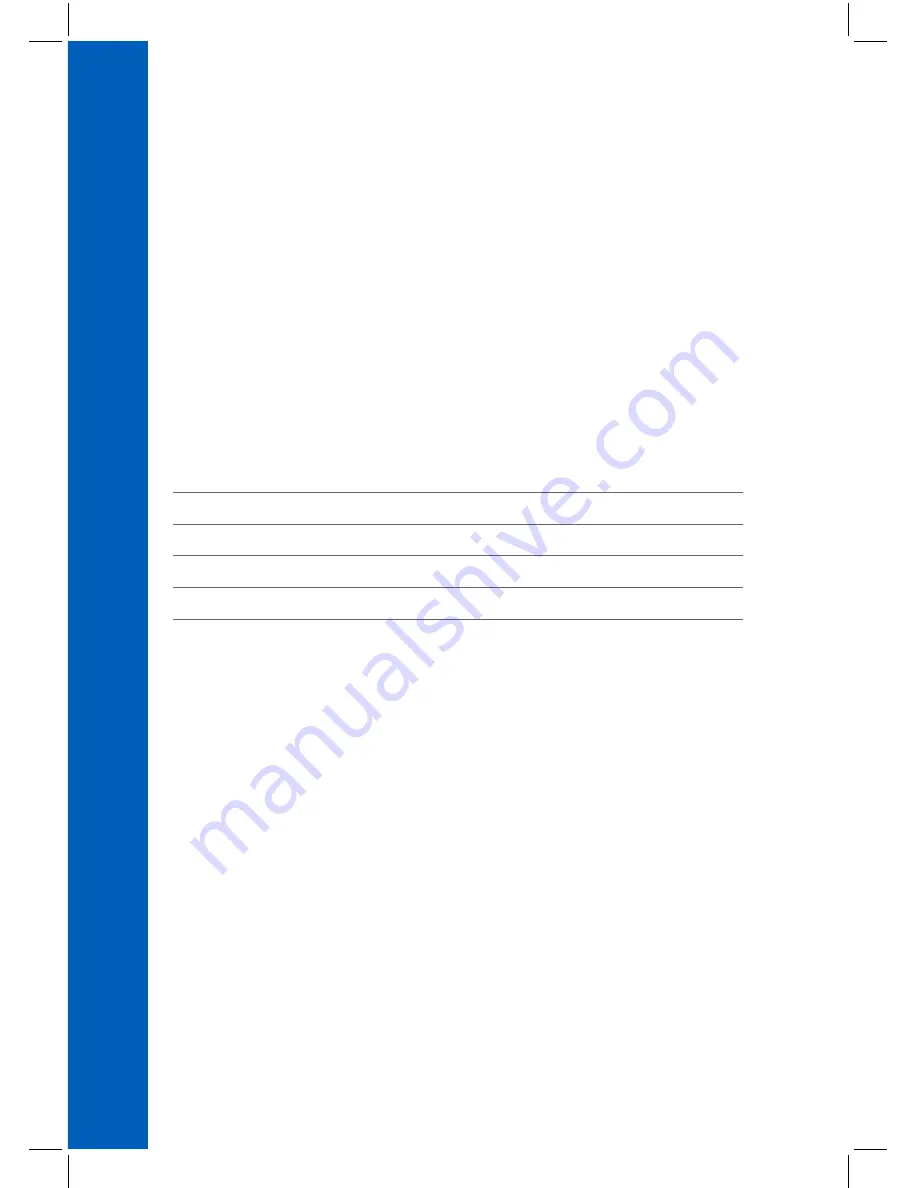

Use the table below to determine the treatment required.

First locate the typical sample pH. If the corresponding ORP value (mV) is higher than the values in

the table below, an oxidizing pretreatment is necessary. If the value is lower, a reducing pretreatment

is necessary.

pH

mV

pH

mV

pH

mV

pH

mV

pH

mV

0

990

1

920

2

860

3

800

4

740

5

680

6

640

7

580

8

520

9

460

10

400

11

340

12

280

13

220

14

160

For reducing pretreatment:

immerse the electrode for at least five minutes in

HI7091

.

For oxidizing pretreatment:

immerse the electrode for at least five minutes in

HI7092

.

D.O. Sensor Activation

The D.O. probe is shipped dry. To prepare the sensor for use:

• Remove the black & red plastic cap. This cap is used for shipping purposes only and can be thrown

away.

• Insert the supplied O‑Ring in to the membrane cap.

• Rinse the membrane with some electrolyte solution. Refill with clean electrolyte.

Gently tap the membrane cap to dislodge air bubbles. To avoid damaging the membrane, do not

touch it with your fingers or directly tap the membrane.

• With the sensor facing down screw the membrane cap counterclockwise to the end of the threads.

Some electrolyte will overflow.

• Rinse outside of sensor with deionized water.

• Invert sensor and inspect. There should be no bubbles or debris between the membrane and

sensor body.

Summary of Contents for HI98194

Page 9: ...9 SENSOR AND PROBE INSTALLATION ...

Page 25: ...25 SETUP MENU STRUCTURE ...