ACL00120

H

J

E K

D

A

B2

B1

E

K

FOOT CAP

C

IMPORTANT!! PLEASE READ ENTIRE INSTRUCTION SHEET BEFORE ASSEMBLY!!

TO EXPEDITE ANY FUTURE WARRANTY CLAIMS, PLEASE KEEP INSTRUCTION SHEET, WARRANTY CARD AND RECEIPT

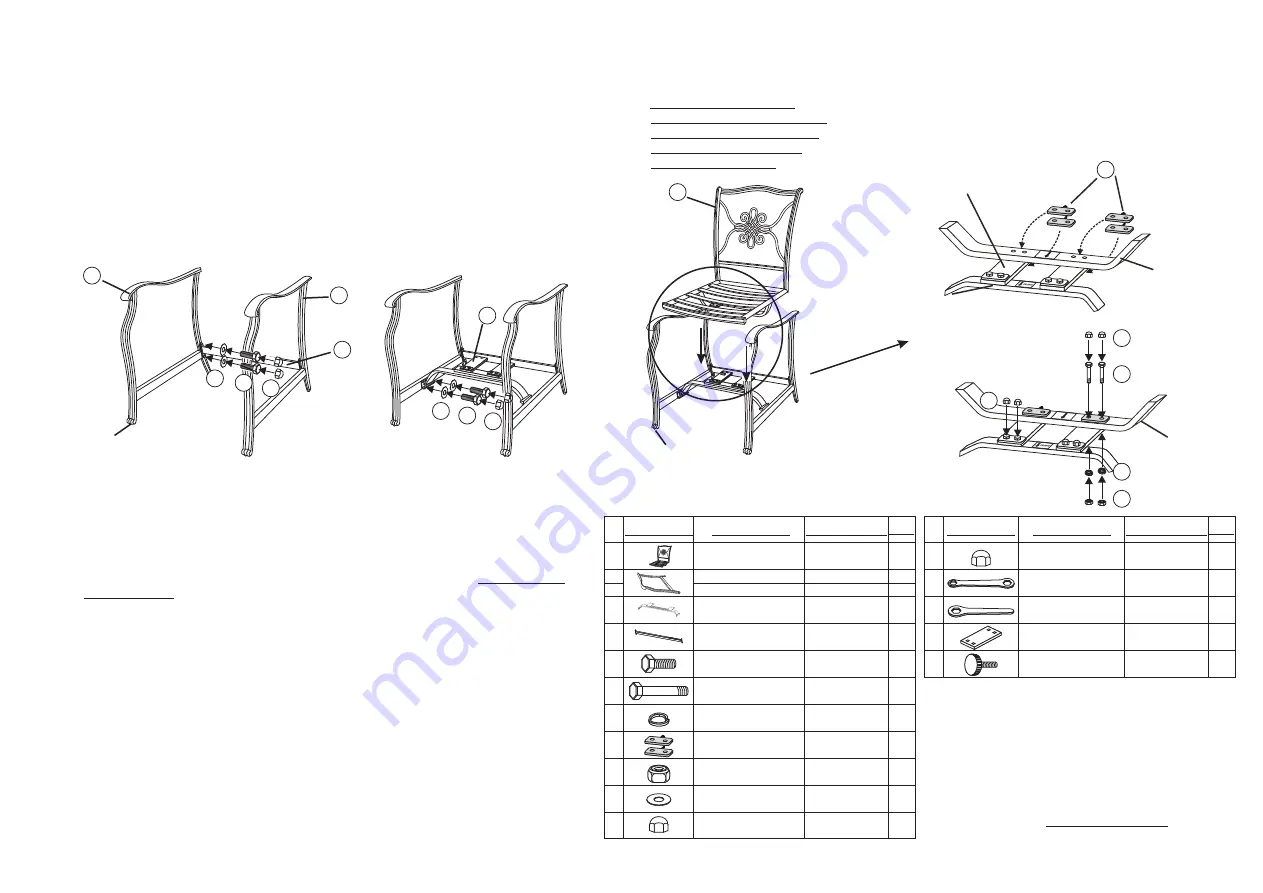

Fig. 1

Fig. 2

Fig. 3

NOTE: MAKE SURE ARROWS

FROM BOTH THE "U" BAR

AND ROCKER ASSEMBLY

ARE POINTING IN THE

SAME DIRECTION!

Page

HEX WRENCH-1

HW0009

1

HEX WRENCH-2

HW0007

1

G0314

BOLT COVER-2

HW0028

8

QTY

QTY

5/16" X 40 MM

BOLT

HW0003

5/16" NUT

HW0015

CHAIR FRAME

SUPPORT BAR

LEG SUPPORT

LEFT LEG

RIGHT LEG

PARTS LIST

PARTS LIST

DESCRIPTION

DESCRIPTION

ORDER PART #

ORDER PART #

4

4

4

1

1

1

1

1

4

HW0295

HW0618

* NOTE: PARTS SHOWN ON PARTS LIST ARE NOT TO SCALE

A

C

D

E

F

G

H

I

J

K

L

M

N

ROCKER PLATE

FACTORY ASSEMBLY

Ø8.0 X 2.3 MM

SPRING WASHER

B1

B2

HW0004

8

Ø6.5 X 1.0 MM

WASHER

FOOT CAP

HW0442

BOLT COVER-1

8

1/4" X 20 MM

BOLT

HW0465

8

Fig. 4

Fig. 5

Step 1:

Do not attempt assembly if

any parts are missing or damaged.

Step 2:

Fig 1

Hand tighten only

Step 3:

Fig 2

Hand

tighten only

Step 4:

Do not over tighten. Over tightening may strip bolts.

Step 5:

Fig 3

If chair frame has been properly positioned on the rocker assembly, all arrows on the "U" bar

and rocker assembly will be pointing in the same direction.

Step 6: Critical Step: The "U" metal plates must be installed in the proper location.

Fig 4

Fig 5 Hand tighten only.

CAUTION: Failure to place "U" metal plates under the rocker plates and above the "U" bar exactly as

shown in diagram will cause the bolt heads and nuts to damage the structure of the rocker plates and the

"U" bar. Damage due to over tightening of bolts or improper assembly could cause injury and may void

your warranty.

Step 7:

Do not over tighten.

Step 8:

.

,

.

,

.

.

.

,

,

.

Identify all parts packed in the carton against the parts list. Remove all protective materials. Place parts

on a non-abrasive surface to avoid scratching. If you are missing any parts or are unsure how to proceed

with the assembly, call our Customer Service Center at 1-800-416-3511.

Attach the leg support to the chair legs(B1 & B2) by using the 1/4"x20 mm bolts and washers as shown

in

. Guide these bolts through the holes in the leg support into pre-drilled holes in the chair legs.

.

Attach the support bar to the chair legs by using the 1/4"x20 mm bolts and washers as shown in

.

Guide these bolts through the holes in the support bar into the pre-drilled holes in the chair legs.

.

At this time make any adjustments to alignment of all parts. Tighten all bolts a few revolutions at a time,

alternating between bolts until tightened.

Set the chair frame on the rocker assembly with front of the seat facing you and the arrows on the "U"

bar pointing towards you as shown in

. This is very important for a safe, balanced rocking motion.

Adjust alignment of the holes of support bar and "U" bar Insert a "U" metal plate

as shown in

. Then guide the 5/16"x40 mm bolts through the holes in the "U" metal plate “U” bar,

rocker plate and bottom portion of the “U” metal plate. Add a Ø8.0 x 2.3 mm spring washer and a nut

to each bolt as shown in

.

Repeat the same procedure on the other side.

Tighten all nuts and bolts with the hex wrenches provided.

Remove arrow labels

from "U" bar and rocker assembly. Cover all bolts with bolt covers.

Your chair is ready for use. If you need any assistance, please call our Customer Service Center

at 1-800-416-3511.

Read this step and

carefully examine.

IMPORTANT NOTE: Damage to welds or frames resulting from over tightened bolts or improper

assembly is not covered under our warranty. Please read all instructions carefully before assembly. If you

have any questions regarding your assembly, call our Customer Service Center at 1-800-416-3511.

SEAT DESIGNS MAY

VARY BUT THE ASSEMBLY

IS THE SAME

ROCKER PLATE

"U" BAR

ROCKER

ASSEMBLY

"U" BAR

FC0030

FOOT CAP

FACTORY ASSEMBLY

"U" METAL PLATE

L

L

F

G

I

J