10

f) record the equipment, thermometer etc. used for

the measurements

Table A: Guide to maximum stabilised tem-

peratures recorded during site tests

Application

Mixed water

temperature

Shower

43°C

Washbasin

43°C

Bath (44°C fill)

46°C

Bath (46°C fill)

48°C

The mixed water temperature at terminal fitting should

never exceed 46ºC.

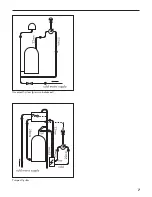

If there is a residual flow during the commissioning or

the annual verification (cold water supply isolation test),

then this is acceptable providing the temperature of

the water seeping from the valve is no more than 2°C

above the designated maximum mixed water outlet

temperature setting of the valve.

Temperature readings should be taken at the normal

flow rate after allowing for the system to stabilise.

The sensing part of the thermometer probe must be fully

submerged in the water that is to be tested.

Any TMV that has been adjusted or serviced must be

re-commissioned and re-tested in accordance with the

manufacturers' instructions.

Commissioning and in-service

tests

Commissioning

Purpose

Since the installed supply conditions are likely to be

different from those applied in the laboratory tests it is

appropriate, at commissioning, to carry out some simple

checks and tests on each mixing valve to provide a

performance reference point for future in-service tests.

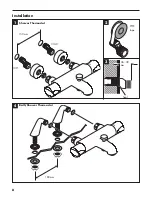

Procedure

1.

Check that:

a) the designation of the thermostatic mixing valve

matches the intended application

b) the supply pressures are within the range of ope-

rating pressures for the designation of the valve

c) the supply temperatures are within the range per-

mitted for the valve and by guidance information

on the prevention of legionella etc.

2.

Adjust the temperature of the mixed water in accor-

dance with the manufacturer’s instructions and the

requirement of the application and then carry out the

following sequence:

a) record the temperature of the hot and cold water

supplies

b) record the temperature of the mixed water at the

largest draw-off flow rate

c) record the temperature of the mixed water at a

smaller draw-off flow rate, which shall be measu-

red

d) isolate the cold water supply to the mixing valve

and monitor the mixed water temperature

e) record the maximum temperature achieved as a

result of (d) and the final stabilised temperature

NOTE: The final stabilised mixed water temperature

should not exceed the values in Table A.