Hansa C27EU O&M Manual

– OM-023 Revision A 16/10/19

© Hansa Chippers 2019

4

Feeding material

Cuts and scrapes

Wear tight fitting safety gloves

Wear tight fitting long sleeves and pants to cover bare skin

when operating the machinery

Weight of the chipper

Straining, crushing

Place the machinery on level ground

Do NOT

attempt to move the machinery up/down

slopes unless is attached to a towing vehicle

Petrol, oil, grease

Poisoning, skin irritation,

harmful vapours

Take care when handling petrol, oil and grease

Wash skin if contaminated with petrol, oil or grease

Do NOT

refuel the chipper in enclosed areas

Towing safety

Rotate the discharge chute to face the opposite direction of the towing vehicle before towing and lock into position.

Lock the feed table in the up position.

Do not exceed maximum towing speed of 90km/hr.

Connect the tow coupling to the towing vehicle (check the ball dimensions are the same as the coupling).

Connect safety chain with shackle.

If the machine is fitted with brakes, check handbrake is off and road brakes are on by removing the reversing lever.

Plug in lights and check they are operational.

Check wheel nuts and axle U-bolts periodically to make sure they are secure.

Ensure the jockey wheel is in the up position and locked away during transport.

Ensure the rotating assembly is positioned facing forwards (with the engine at the front, feed chute at the rear) and the

chassis rotation locking pins are down in the locked position.

Operation

The chipper is self-feeding and has a large inlet opening. It can process:

•

Prunings, stalks, vines, leaves, roots and vegetable matter, paper and cardboard

•

Freshly cut material is better to process than dry material

•

Maximum capacity is 160 mm diameter branches

It is recommended to keep a wooden stick handy, approx. 60 mm diameter x 1000 mm long for:

•

Pushing in short, brushy and very leafy materials

•

Keeping the inlet table clear

Outlet chute adjustment

The C27 is fitted with a freely rotating outlet chute, allowing the operator to precisely

control the direction of material discharge from the machine. The chute can easily be

adjusted by undoing the clamping bolt, adjusting the outlet chute direction as needed, then

doing the clamping bolt back up.

Additionally, the end of the outlet chute is fitted with two deflector plates that you can

adjust to control the angle and distance that material is discharged. A wingnut is located on

the side of the upper deflector to lock it in place.

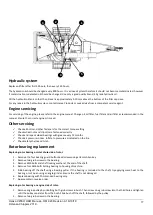

360-degree turntable adjustment

The chipping components of the C27 are coupled to the chassis via

a freely rotating turntable. This allows the operator to feed material

into the chipper from any direction, eliminating the time and effort

spent repositioning the machine, and allowing you to use the

chipper while still being coupled to the tow vehicle. To reposition

the turntable, lift the locking pins on each side of the chipper, rotate

the chipper, then resecure the pins. Check the table is locked

properly by ensuring each pin locks into one of the 24 positions on

the base of the turntable.

Locking pin

in the ‘locked’

position