Hansa C4 O&M Manual - OM-005 Revision F 20/06/2019

© Hansa Chippers 2019

10

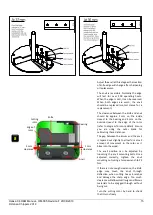

Processing fibrous material

The C4 can process palm fronds, flax, cabbage tree leaves and other similar fibrous material. The machine

’

s cutting disk is

cantilevered (supported on the engine side with two bearings), therefore there is no risk of anything fibrous wrapping around the

shaft and working its way into the bearings. The resulting output is not as consistent as that of branch material due to the fibrous

nature. When processing fibrous material, take note of the following points:

Blades must be sharp to process fibrous material

Fibrous material is best introduced to the machine as a bundle

Fibrous material should be introduced slowly into the machine. Tease the material in and out while feeding it into the

cutting mechanism, ensuring it is not drawn through the machine without being cut properly

Do NOT

extend hands past the rubber flap while doing so

Fibrous material is processed more effectively when it is green rather than when dried

Storage

Always allow the chipper to cool before storing

Store the chipper out of the reach of children

Store the chipper where fuel vapor will not reach an open flame or spark

Switch the fuel lever to the off position

For extended storage periods, run the engine dry of fuel

Store the chipper out of the rain

Water can rust the steel body of the chipper

Transportation

The C4 is designed to be moved by one person using both handles at the top of the inlet chute to lean the chipper backwards and

transfer its weight onto the wheels. The chipper can then be wheeled to and from the work location.

Take care when moving the C3e up and down stairs or kerbs

The wheels can be damaged by the shock loading caused by uncontrolled ascent/descent

The chipper is heavy and the operator can lose control of the machine

Do NOT

move the chipper while it is running

The optional C4 chip catcher bag should be removed from the chipper when transporting or moving to

avoid damage to the bag.

Troubleshooting

What to do if:

The chipper

won’t start

•

The engine oil level might be too low

The chipper is fitted with oil alert and will not start if the oil level is too low

Check the oil level and top up if required

•

The chipper is placed on a slope

The chipper is fitted with oil alert and will not start if the oil is not level

Move the chipper to level ground

Belt drive engagement will not work

•

The inlet chute or housing might be blocked