10

A100g

JULY 2017

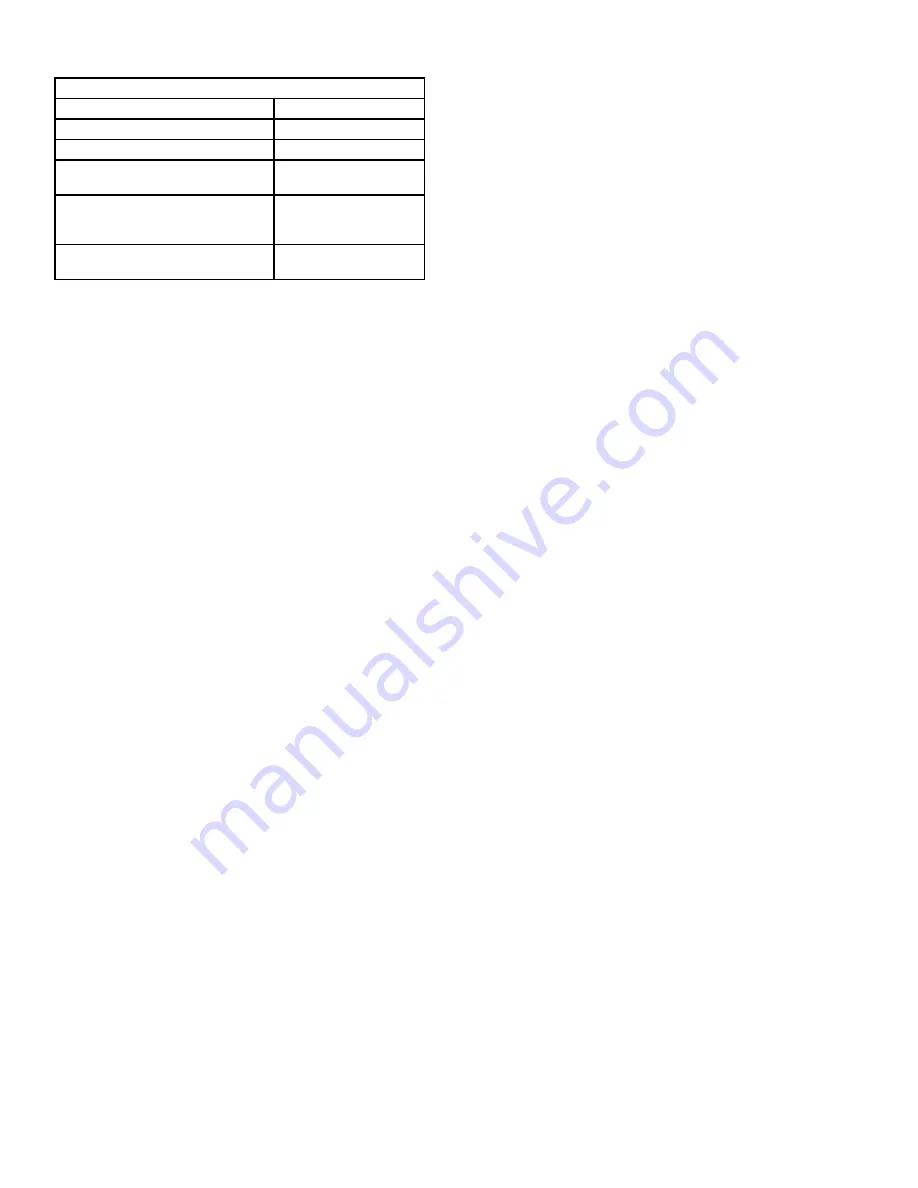

LED LOGIC

GAS SENSOR LED INDICATORS

LED OPERATIONS

RESULT

Green LED Flashing / Red LED off Warming up ≈ 5 min

Green LED on / Red LED off

Ready to detect gas

Green LED on / Red LED on

Gas level above gas

sensor trip point

Green LED off / Red LED on

Sensor element

failure or sensor

disconnected

Green LED off / Red LED flashing

Low supply voltage or

low supply current

TABLE 3

CALIBRATION PROCEDURES

Refer to Fig. 12 for calibration of Hansen sensors.

Equipment required:

Hansen calibration kit, stopwatch, hex wrench; 5/32˝,

long nose pliers, 24V AC/DC power supply, voltmeter,

2 minigrabber voltmeter leads and calibration gas for

the specific sensor.

Setup:

1. B e s u r e t h e s y s t e m i s m a d e s a f e d u r i n g

calibration. The 4-20mA output and internal relay

will be active during calibration.

2. Be sure the gas sensor has been powered up for a

minimum 24 hours to stabilize the sensing element.

3. Verify the green LED is illuminated and the red LED

is off.

4. Disable the internal horn by removing JP2 jumper.

Zero Calibration:

5. Set the voltmeter to the appropriate DC range. The

sensor element output is measured in DC volts;

zero volts equals zero PPM and 5 volts equals the

gas sensor PPM rating. (i.e. 100 PPM, 250 PPM).

Attach the voltmeter leads to the VS, (+) lead from

the voltmeter, V0, (-) lead of the voltmeter.

6. Be sure the ambient atmosphere around the gas

sensor is free of any background gases. To zero

CO2 sensors, pure nitrogen needs to be used to

ensure free ambient conditions.

7. Adjust the zero potentiometer (Z) until the voltage

reading on the voltmeter reads between zero volts

and +/- 0.030VDC.

Span Calibration:

1. Always perform the zero calibration before doing

the span calibration.

2. Place the boot over the sensor element. Use the

correct concentration of calibration gas for the

full range of the sensor. In other words, for a gas

sensor with a range of 0 to 250 PPM, use a 250 PPM

calibration gas when setting the span. If full range

calibration gas is not available, a calibration gas of

less than full range can be used then adjust to the

corresponding output voltage. This may result in

some loss of accuracy.

3a.

G a s s e n s o r s ( e x c e p t V e n t l i n e a n d

S e m i - c o n d u c t o r g a s s e n s o r s ) .

Start the flow of gas. Observe the output, it should

begin to increase after 5 seconds. Leave the gas

flow on and observe the voltage. The sensor voltage

will slowly climb toward 5VDC. When the voltage

does not change by more than +/- 0.010 volts per 15

seconds the sensor output voltage is considered to

be stable. Adjust the span potentiometer (S) so the

output voltage reads between 4.95 to 5.00 volts DC.

3b.

Vent line and Semi-conductor gas sensors

Start the flow of gas. Observe the output, it should

begin to increase after 5 seconds. Leave the gas

flow on and observe the voltage. The sensor voltage

will ramp up quickly. When the voltage does not

change by more than +/- 0.010 volts per 15 seconds

the sensor output is considered to be stable. Adjust

the span potentiometer (S) so the output voltage

reads between 4.95 to 5.00 volts DC.

4. Stop the flow of gas and remove the boot from the

sensor element. Verify the sensor voltage output

begins to decrease.

5. Do not attempt to re-adjust the zero or span

calibration until another 24 hours of powered

operation has passed.

6. Enable system. Verify proper operation.

7. Enable the internal horn by installing JP2 jumper.

Electrochemical Sensor Only (Zero Offset)

If the gas sensor is calibrated in the environment for

which it will be used a final zero adjustment will not be

necessary. If the gas sensor will be calibrated at one

temperature (70ºF, 21ºC) then moved to its operating

environment (-4ºF, -20ºC) a maximum zero offset of

2% will occur. If unacceptable, adjust the zero point as

described in section

Calibration Procedures, Zero

Calibration

. At (-40ºF, -40ºC), a maximum zero offset

of 12% will occur. If unacceptable, adjust the zero point

as described in section

Calibration Procedures, Zero

Calibration

.

CALIBRATION GAS CYLINDERS

Warning: Refer to Material Safety Sheet supplied with

gas cylinder and local safety precautions for proper

usage, handling and disposal.

Hansen calibration gas standards are traceable to NIST

(National Institute of Standards and Technology) and

analysis data is available on request.

A variety of calibration refrigerant gases and PPM ranges

are available, refer to Page 23. For special mixtures,

consult factory. Calibration gas should be stored in a

cool area, 65ºF/75ºF. Shelf life labeled on cylinder−one

year from date of manufacture.

Calibration gas must be shipped according to Department

of Transportation Hazardous Gas Regulations. Special

shipping charges will apply. Shipping only available in

the continental USA.