-10-

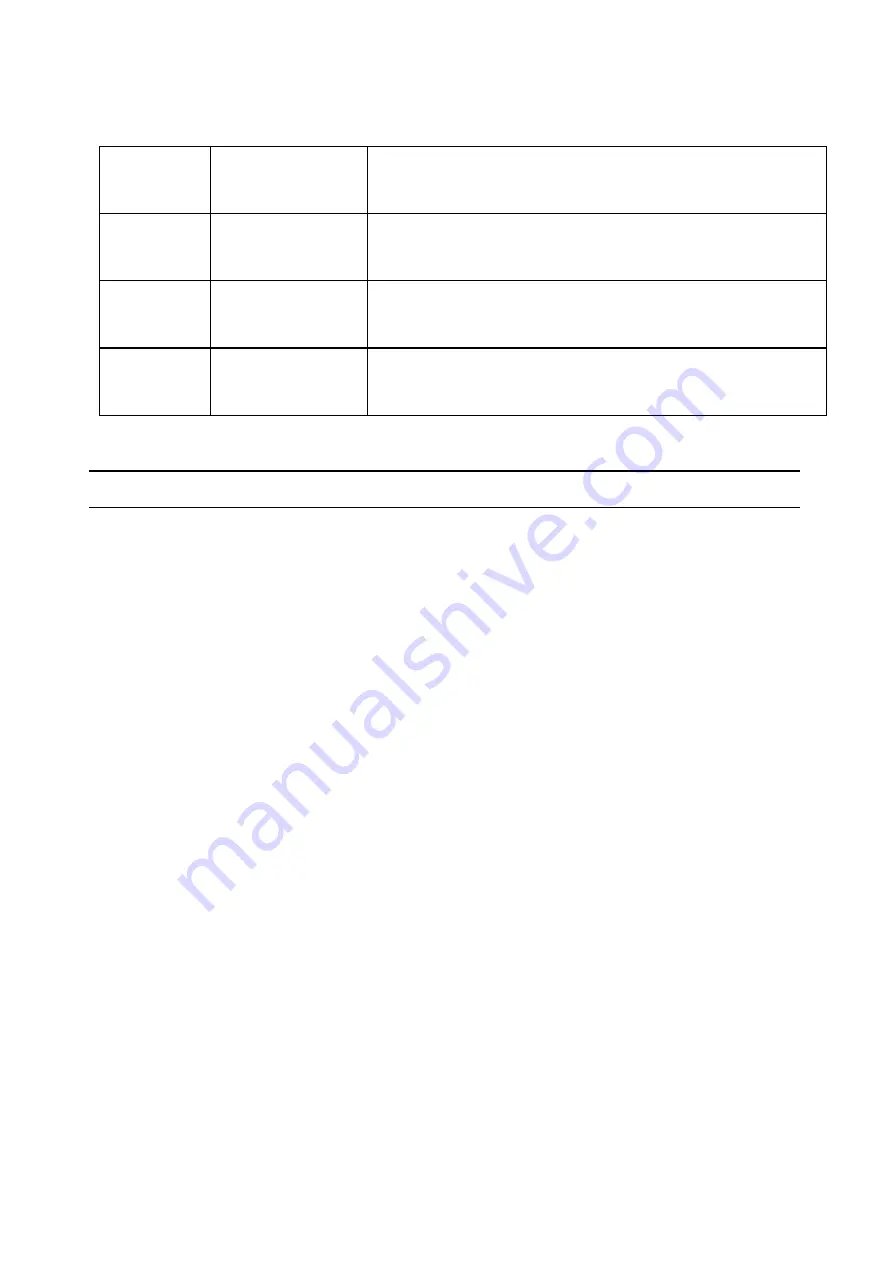

Table 4 Wire feeder panel function introduction

Serial

number

Names

Functions

1

Current adjustment

knob

Used to adjust welding current, when preset the current, it

will display the relative graduated value from 2-100.

2

Manual wire

feeding button

Used to feed the wire into torch before welding.

3

Voltage adjustment

knob

Used to adjust voltage.

6. OPERATION

6.1 Preparation

a. Switch the power on, the power indicator light of the welder will be on, the fan starts to

work. N.B. When pressing the torch switch, there will be an out voltage, the shell of the

heating pressure reducing flow meter will heat up.

b. Choose the appropriate wires based on different workpiece, then choose the right wire-

feeding wheel, nozzle based on the wires chosen.

c. Press ‘Manual wire-feeding’ button, wire is then fed into the torch.

d. Switch to ‘Gas test’ on the torch panel, adjust the flow meter valve, choose the appropriate

flow, and then switch to ‘welding’ status.

6.2.1 Spot weld and short seam weld

a. Switch the end arc ON/OFF to ‘OFF’ position.

b. Adjust the ‘welding current’, ‘welding voltage’ knobs according to welding preference.

c. Press the torch switch, the welder will start working; release the welding torch switch,

welding process will be stopped. When using the welding trolley, press ‘start’, welder will

start working; press ‘start’ again, welding process will be stopped.