-

11

-

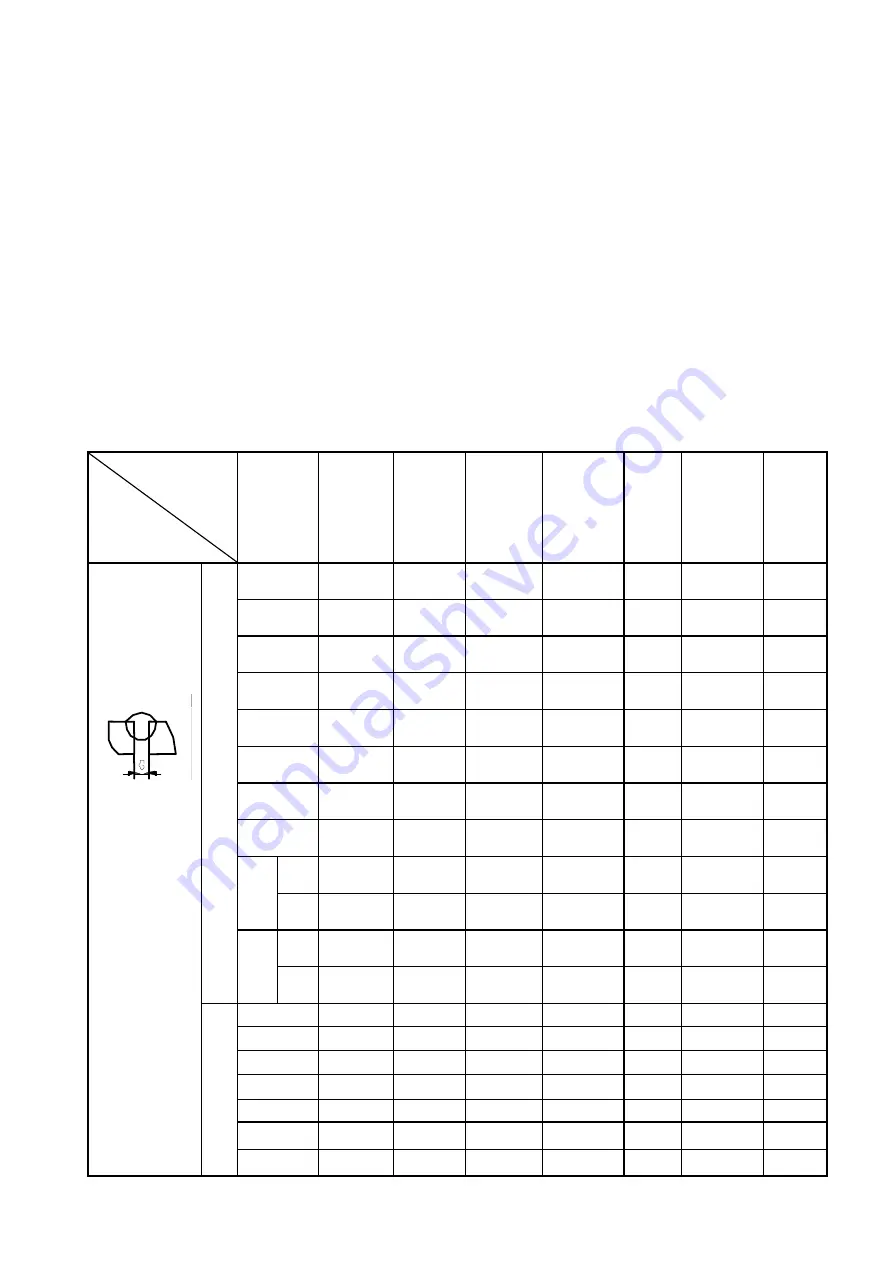

6.2.2 Long weld seam and large current welding

a. Switch the end arc ON/OFF to ‘ON’ position.

b. Adjust the ‘welding current’, ‘welding voltage’ knobs according to welding preference.

c. Press the torch switch, arc will be ignited, then the welder will enter normal working state,

the torch switch can be now release, the welder will continue to weld; press the torch switch

again, the welder will enter an ending arc (filling arc crater) state, and output a smaller norm,

now release the torch switch, the welder will stop welding.

6.3 process specification

Table 5 welding technology specification 1

Plate

thickness

(mm)

Wire

diameter

Φ

(mm)

Root

gap

(mm)

Welding

Current

(A)

Welding

Voltage

(V)

Weldi

ng

speed

(cm/

min)

Distance

between

nozzle

and base

metal

(mm)

Gas

Flow

(L/min)

I-shaped

butt welding

Lo

w

sp

eed

co

nd

itio

n

0.8

0.8,

0.9

0

60

70

16

16.5

50

60

10

10

1.0

0.8,

0.9

0

75

85

17

17.5

50

6

0

10

10

15

1.2

0.8,

0.9

0

80

90

17

18

50

6

0

10

10

15

1.6

0.8,

0.9

0

95

105

18

19

45

50

10

10

15

2.0

1.0,

1.2

0

0.5

110

120

19

19.5

45

50

10

10

15

2.3

1.0,

1.2

0.5

1.0

120

130

19.5

20

45

50

10

10

15

3.2

1.0,

1.2

1.0

1.2

140

150

20

21

45

50

10

15

10

15

4.5

1.0,

1.2

1.0

1.5

170

185

22

23

40

50

15

15

6.

0

1.2

1.2

1.5

230

260

24

26

40

50

15

15

20

1.2

1.2

1.5

230

260

24

26

40

50

15

15

20

9.

0

1.2

1.2

1.5

320

340

32

34

40

50

15

15

20

1.2

1.2

1.5

320

340

32

34

40

50

152

15

20

H

igh

sp

eed

co

nd

itio

n

0.8

0.8,0.9

0

89

16.5

120

10

15

1.0

0.8,0.9

0

100

17

120

10

15

1.2

0.8,0.9

0

110

18

120

10

15

1.6

1.0,1.2

0

160

19

120

10

15

2.0

1.0,1.2

0

180

20

80

15

15

2.3

1.0,1.2

0

200

22

100

15

20

3.2

1.2

0

240

25

100

15

20