11

-

18

Hanskamp AgroTech BV (The Netherlands)

www.hanskamp.com

L

’

port

EN

Sluithek

-

Closing gate

-

Schließbügel

-

Porte arrière automatique

Operation

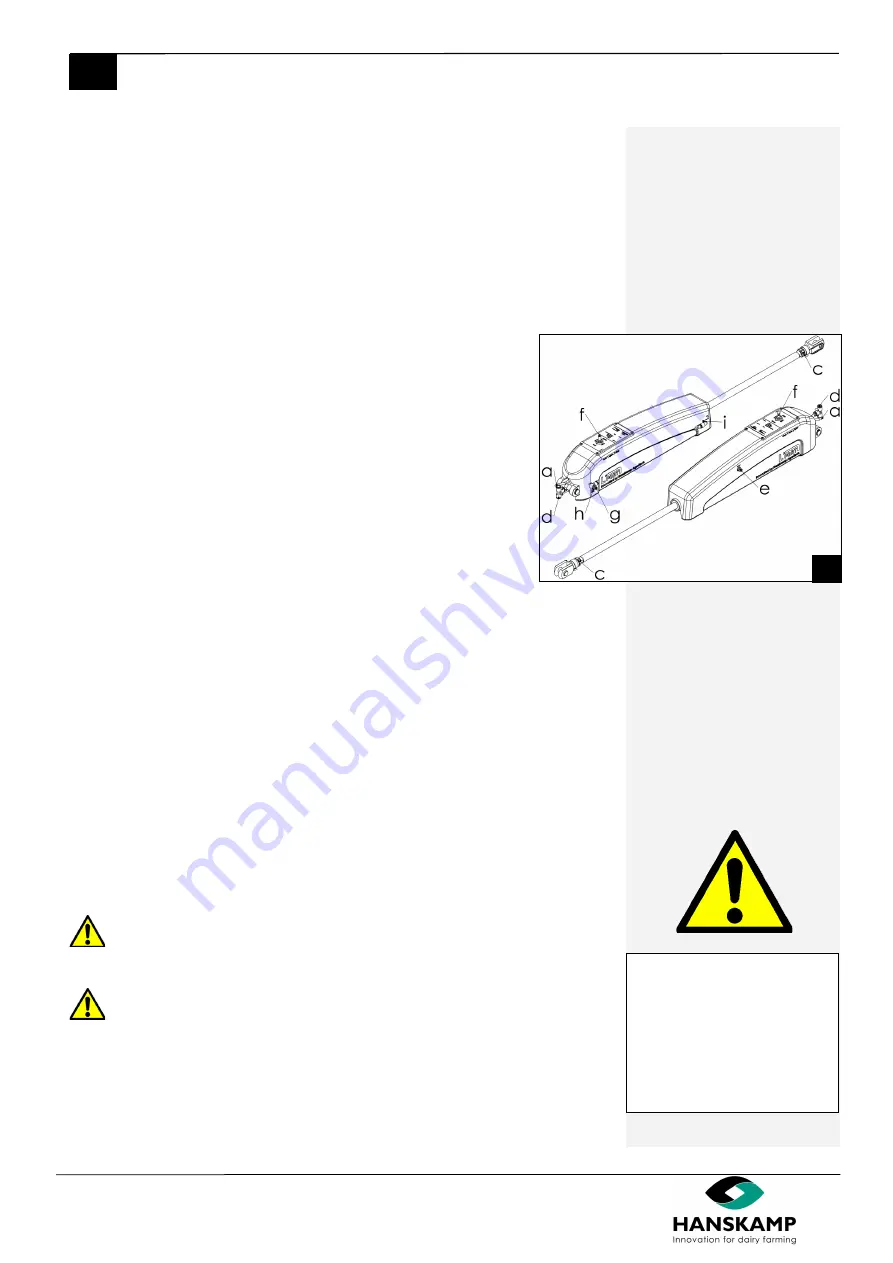

With the 3

-

Position Switch (fig. 10.f) a choice can be made to open the L

’

port closing

gate (Open), to close the L

’

port closing gate (Close) or to have the L

’

port closing gate

operate automatically (Auto). In position

‘

Automatically

’,

the L

’

port closing gate will

close when the feed motor receives an electrical pulse. The L

’

port closing gate will open

after a delay time. The delay time will automatically reset when the feed motor has re-

ceived a new electrical pulse. This delay time can be set via the 14

-

positions switch on

the L

’

port Control PCB (time setting in sec.) (fig. 9). The delay time has to be bigger than

the total interval time of the used feed kinds. Recommendation: interval time + 25 sec-

onds.

Meaning

With the brands of DeLaval, Fullwood, Insentec, Hokofarm and GM time

has to be set at 40 seconds (pos. 4). With Nedap VC control: add the inter-

val time of the used feed kinds + 25 seconds. So, with one feed kind 40

seconds (pos. 4), with two feed kinds 60 seconds (pos. 6) etc. A spray in-

stallation to be connected on the

‘

Spray

’

output is optional.

Explanation position

-

switch delay time

Time setting in sec.

0 = 05 sec.

A = 100 sec.

1 = 10 sec.

B = 110 sec.

2 = 20 sec.

C = 120 sec.

3 = 30 sec.

D = 130 sec.

4 = 40 sec.

E = 140 sec.

5 = 50 sec.

F = 150 sec.

6 = 60 sec.

7 = 70 sec.

8 = 80 sec.

9 = 90 sec.

Adjustment

1.

Adjust the length of the cylinder

-

rod to the fork (fig. 10.c) so that it puts pressure

on the anti

-

jump gate in the lowest position.

2.

With the

‘

Speed in

’

adjusting possibility, that is indicated on the lid with

‘

Speed

in

’

(fig. 10.g), it is possible to set the ingoing speed of the cylinder

-

rod. Be sure

that the L

’

port moves in ±3 sec, from bottom to top position.

3.

With the

‘

Speed out

’

adjusting possibility, that is indicated on the lid with

‘

Speed

out

’

(fig. 10.e), it is possible to set the outgoing speed of the cylinder

-

rod which

has to be ±5 sec.

4.

With the

‘

Cushioning

’

adjusting possibility, indicated on the lid with

‘

Cushioning

’

(fig. 10.h & i), the end cushioning can be set to a fluent end stop of

the rod. The adjust tool is 2.5 mm hexagon socket.

Please note! When the above adjustment steps are not observed correctly, this

may reduce the durability of the L

’

port Closing gate drastically.

Danger! Check whether the air lines are properly connected and that they are

not pinched before pressure is placed on the lines. In the event of incorrect

connection, the output force of the cylinder can be increased, resulting in

serious pinching hazard.

Start

-

up

After installation: Leave the L

’

port closing gate open for one week by putting the switch

on

‘

Open

’

(fig. 10.f), so that the cows can get used to the new installation. After this

week the installation can be put into operation, by placing the switch (fig. 10.f.) to

‘

Auto

’.

The sound level always equals 70 dB (A) or less.

Caution

Attention! Danger of

getting jammed.

Attention! L

’

port closing gate

starts automatically.

Attention! Risk of impact from

the L

’

port closing gate when

walking in.

10