3 - 19

Hanskamp AgroTech B.V. (the Netherlands)

www.hanskampagrotech.nl/en

PipeFeeder HighSpeed

EN

t.b.v carrousel

24VAC & 12-24VDC

1.

Introduction

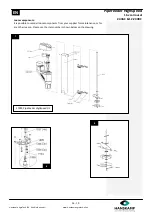

The PipeFeeder High Speed suits all types of milking or feeding carousels and can be lin-

ked to any brand or type of feed computer. The stainless steel pipe holds the stock of

concentrate. As a feed trough of the carousel comes under the PipeFeeder the electric

motor of the dosator gets a signal via the sensor. The PipeFeeder immediately releases

the required feed quantity on time, very rapidly and precisely.

Once the PipeFeeder High Speed receives a signal that all the concentrates have been

released on time it shuts down at once. Any concentrate left in the pipe will fall into the

trough so dairy cow and goat farmers can be assured that with the PipeFeeder High

Speed livestock always get exactly the right amount of concentrates.

The information in this manual is for farmers and technicians.

Dairy farmers use the information to test and adjust the PipeFeeder or to list over-

views.

Technicians use the information to install and setup the PipeFeeder.