BS03 fixed gas detector operation manual

8

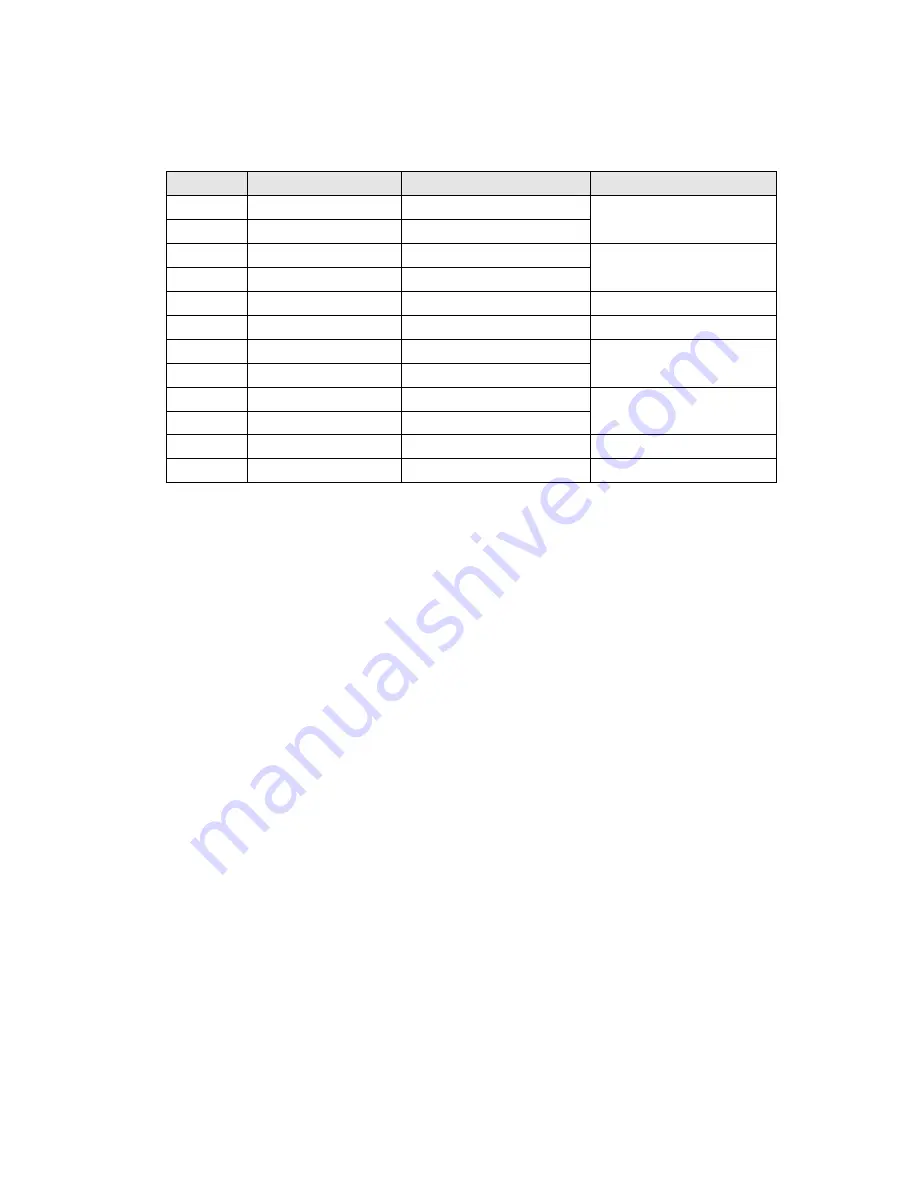

B. If the output signal is RS485 signal, then the terminal definitions are as

below:

4)

After the correct wire connection, take out the useless wire from the

enclosure. Then tighten the compaction circle, rubber air-proof circle and

wire. Explosion-proof soft tube can also be connected with the device directly.

Note:

The size of the connection wire between the controller and detector

should not be less than 6mm, and the distance should be note more than

1000m.

5)

After checking all the connection well, install the display PCB and the

front cover. Make sure O-type circle is put on and connected with the cover

tightly.

6. Operation

On the remote controller, there are totally five buttons as follows: “Setup”,

“Confirm”, “Cancel”, “+” and “-”.

Warning:

It's forbidden to replace the batteries for the remote control in

working area.

Note

: “Setup”, “Confirm” and “Cancel” are single-spring buttons. These

buttons can only be triggered once even if you press them continuously, and

the interval between two springs should not be less than 1 second. “+” and “-”

are continuous-spring buttons and can be triggered by continuous pressing.

Setting can only be affected after pressing “Confirm”. After setting, press

“Cancel” to return to the normal mode. Effective setting can be kept till the

next setup, even if without power.

NO.

mark

function

spec

1

L-Alarm

Low alarm output

Switching value

2

L-Alarm

Low alarm output

3

24V

Power input

DC24V±25%

4

GND

Power input

5

A

Data communication RS485A

6

B

Data communication RS485B

7

H-Alarm

High alarm output

Switching value

8

H-Alarm

High alarm output

9

24V

Power input

DC24V±25%

10

GND

Power input

11

A

Data communication RS485A

12

B

Data communication RS485B

Summary of Contents for BS03

Page 15: ...BS03 fixed gas detector operation manual 12...

Page 17: ...Attachment 1 Address code settings...

Page 18: ......

Page 19: ......

Page 20: ......