groUndIng

The frame shall be grounded in accordance with local electrical requirements*. If grounding of the modules is

required, a good connection between modules and the grounding hardware is essential for an effective ground. The

anodization on a module frame provides a coating to minimize the corrosion due to weather and it acts as a barrier

that reduces the effectiveness of the grounding connection. For an adequate electrical connection, the grounding

hardware should penetrate the anodized layer.

9

* For UL Products: Only UL listed equipment should be used for bonding to ground. For USA: National electrical code (NEC) Article 250; for Canada: CEC

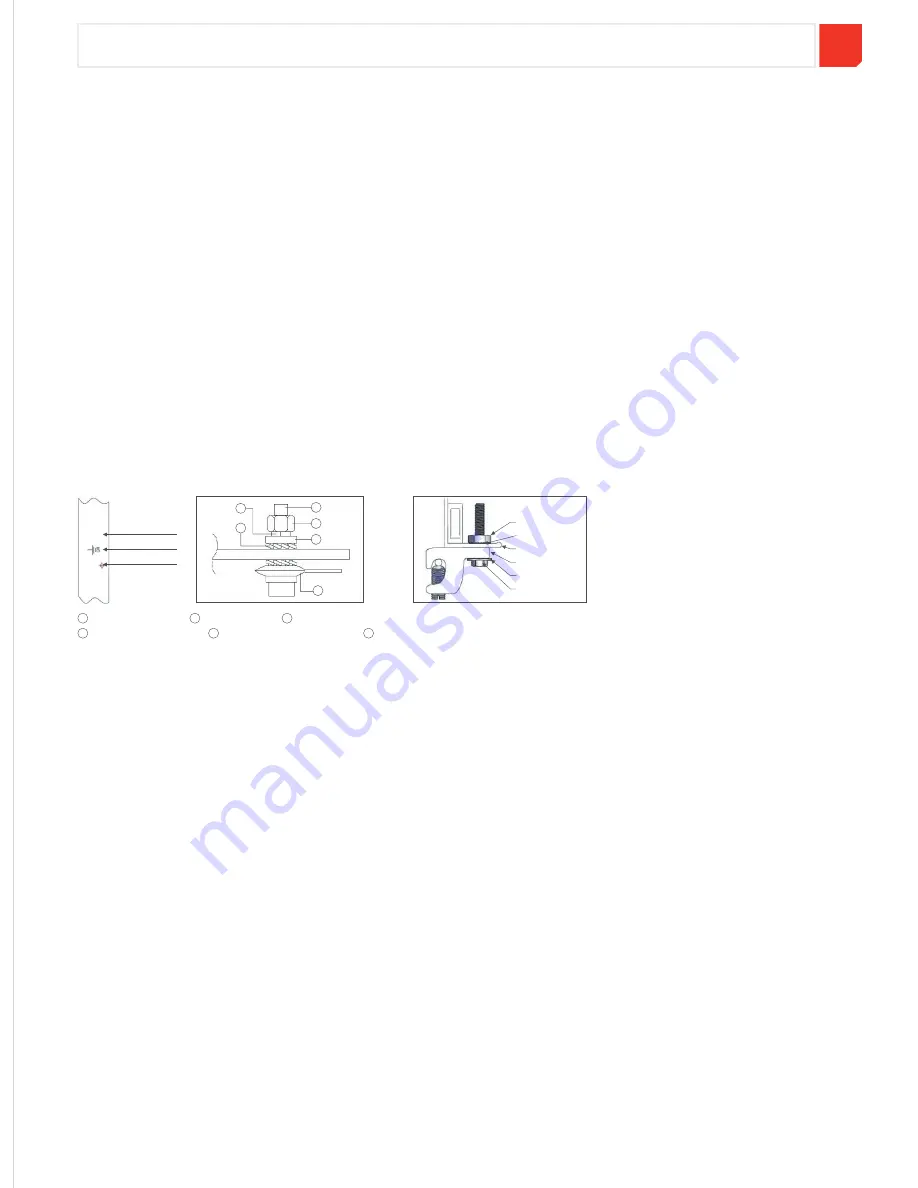

Aluminum frame

Grounding mark

Grounding holes

2-ø4.5

1 Stainless steel bolt M4 × 30 2 Stainless steel nut M4 3 Stainless steel flat washer M4

4 Stainless steel spring washer M4 5 Stainless steel lock-toothed washer M4 6 Stainless steel slotted washer M4

1

2

4

3

5

6

Option 1: Bolting ground

Option 2: Grounding lug with machine screw at frame hole

Select a grounding lug listed for direct burial and outdoor use

(tin-plated, solid copper lay-in lug with a stainless-steel set

screw) capable of accepting a 4-14 AWG copper conductor.

Secure the lug to module grounding hole with a stainless

steel machine screw, flat washer, serrated washer and nut.

Tighten the nut to approximately 2.26 N-m (20 in-lbs).

Tighten the lug set screw to the copper wire at the torque

specified by lug manufacturer.

Nut

Serrated washer

Module frame

Lay-in lug

Flat washer

Machine screw

In case grounding is required, Hanwha Solar recommends using the follow components or equivalents.

IEC/En61730 InformatIon

Hanwha Solar module is designed to fulfill the criteria of Application Class A requirements according to IEC/EN61730-

part1. The modules are qualified for application class A: Hazardous voltage (IEC61730: higher than 50V DC; EN61730:

higher than 120V), hazardous power applications (higher than 240W) where general contact access is anticipated

(Modules qualified for safety through EN IEC61730-1 and EN IEC61730-2 within this application class are considered

to meet the requirements for Safety Class II.

UL LIstIng InformatIon

1.

Rated electrical characteristics are within 10% of measured values at Standard Test Conditions of:

1000W/ m², 25°C cell temperature and solar spectral irradiance per ASTM E892 or irradiance of AM 1.5

spectrum.

2.

The standoff height should be at least 7.9 in. If other mounting means are employed, this may affect the

UL Listing.

3.

The modules have been evaluated by UL for a maximum positive or negative design loading of 30 lbs/ft².

4.

Wiring methods should be in accordance with the NEC.

5.

For installations in Canada, the installation shall also be in accordance with CSA C22.1, safety Standards

for Electrical Installations, Canadian Electrical Code, Part 1.

6.

The use of the following hardware is required in order to provide a reliable grounding connection to the

module frame: a combination of the following stainless steel hardware: Serrated washer, Spring washer,

flat washer, a size M4 nut, and bolt M4x30mm -- (see illustration grounding for details).