Chapter 3 Installation

48

Using the Flexible I/O, you can set the Safety I/O additionally. For example, you can

use the emergency stop output. In addition, you can configure the Flexible I/O for the

safety function in the GUI.

Danger

Do not connect safety signals to normal PLCs. Only safety PLCs must be connected

to safety signals. If you do not comply with the warning, then the safety stop function

may fail, causing severe injury or even death. The safety signal and the general I/O

signal should be separated from each other.

Warning

All the safety class I/O's are duplexed. By separating the channels, you should

make sure the safety function is not initiated by a signal failure.

Before installing the robot, you must check the safety functions. In addition, the

function should be checked for defects periodically.

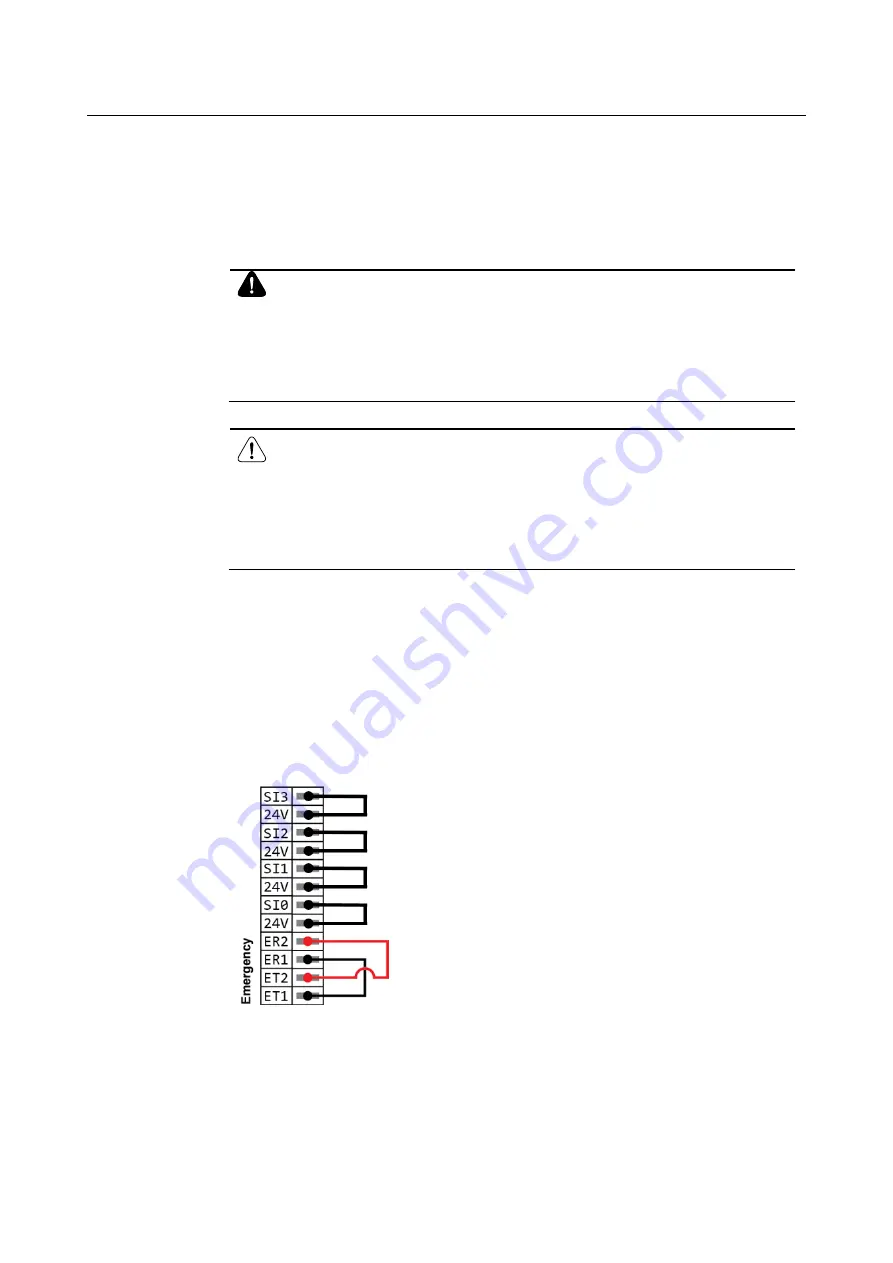

Initial safety configuration

The safety settings of the robot at the factory are as follows.

- Operation software: Unassigned

- Robot controller(Emergency connector): As shown below

Summary of Contents for HCR-3

Page 1: ...HCR 3 Collaborative Robot User Manual Aug 2019 V 2 001...

Page 2: ......

Page 99: ...Chapter 8 Safety Settings 99 3 Press the OK button...

Page 186: ...Chapter 15 Maintenance 186 4 When the confirmation window appears press YES...

Page 190: ...190 Appendix B Certification Safety...

Page 191: ...191 MD Machinery Directive...

Page 192: ...192 LVD Low Voltage Directive...

Page 193: ...193 EMC Electro Magnetic Compatibility...

Page 194: ...194 Appendix C Dimensions for Installation...

Page 200: ......

Page 201: ......