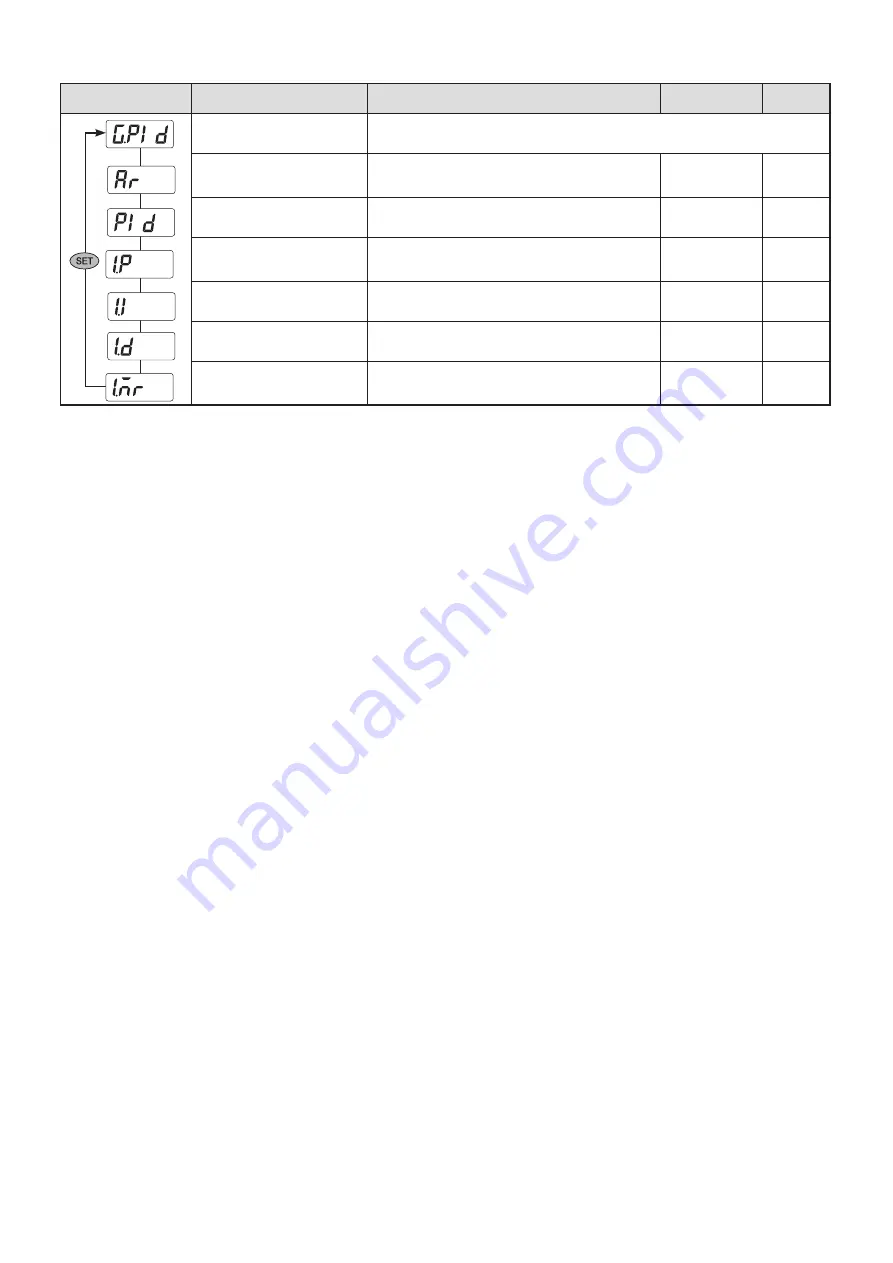

22

Signal

Item

Setup range

Display condition Initial value

PID setup group

Setup below items.

Anti Reset wind up

Auto/50.0 ~ 200.0 %

P.I.D

control

Auto

PID indication group

OFF / P1Gr ~ P4Gr

Always

0

n. Proportion

0.1 ~ 999.9 %

P.I.D

control

5.0 %

n. Integral

OFF / 1 ~ 6000 sec.

Always

240 sec.

n. Differential

OFF / 1 ~ 6000 sec.

Always

60 sec.

Manual reset

-5.0 ~ 105.0 %

Integral

time OFF

50.0 %

8-1-7. PID Setup Group

1) Anti Reset Wind Up :

Anti Reset Wind Up operation is carried out to prevent over-integral when the control output value reached

the limitation. Integral time is not “0” and integral time executes the ARW operation under the following

conditions when AUTO is selected for the auto tuning execution from the auto tuning setup group.

·DV≥0 & output value maximum restriction

·DV<0 & output value maximum restriction

2) Selection of PID Indication Group Number :

The PID control integer possesses 4 types and the operated PID integer can indicate and set up the items

when selecting manual operation. The operative integer of the PID group in agreement with the selected

number from the auto tuning selection in the auto tuning setup group is applied to each pattern segment of

4 types due to the selection of pattern segment PID group number of segment #0 in memory program

setup mode.

3) n. Proportion :

If select PID 1 group (P1GR) from the setup item of PID indication group number selection, 1 group

proportion (1.p) with n. proportion is indicated. Here, the proportional value of the operated 1 group is

indicated and can be changed and set up manually.

4) n. Integral Time :

According to the PID indication group number selection, 1~4 group integral time will be indicated in the

setup item and will be automatically remembered and manually changed/set up due to the auto tuning.

5) n. Differential Time :

According to the PID indication group number selection, 1~4 group differential time will be indicated in the

setup item and will be automatically remembered and manually changed/set up due to the auto tuning.

6) Manual Reset :

If “0” is selected as the integral time, variation occurs in control due to proportionate movement.

Such variation can be eliminated through manual reset.

(Parameter appears only when the integral time is set up “0”)