16

◆

The pressure regulator and hose assembly supplied with LP models must be used.

Connection of the NG supply to the appliance inlet should be made by a qualified installer.

Replacement pressure regulator and hose assemblies must be those specified in this manual.

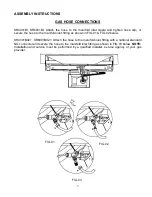

To connect the gas bottle to the unit:

Appropriate Regulators are available from the same dealers, for fitting to the hose supplied with

this unit.

1. Attach the hose to the manifold inlet nipple and tighten hose clip.

Ensure that all connecting threads and surfaces are undamaged, clean and free

from dirt. When fitting the hose make sure that it is free from twisting, kinks or sharp bends.

.

Ensure that all connecting threads and surfaces are undamaged, clean and free

from dirt. When fitting the hose make sure that it is free from twisting, kinks or sharp bends.

Do not allow the hose to touch any hot surface or sharp edges.

2. Attach the regulator to the gas cylinder. Refer to the instructions supplied with the regulator

for details regarding fitting.

3. Test for gas leaks. Do a leak test each time the cylinder is installed, whether or not it has

been filled. Check all other joints at least once a year. lf the hose shows deterioration or

damage, leak test the entire outer surface, while under pressure. Replace at first sign of leak

or age cracking. Remember to turn the cylinder valve OFF before removing the hose. The

hose should be checked at least once per month and each time the cylinder is changed. The

hose must be changed within the prescribed intervals.

To connect the city network gas to the unit:

1. Attach the hose to the manifold inlet fitting with a national standard NG connector and secure

the hose to the manifold inlet fitting.

Ensure that all connecting threads and surfaces are undamaged and clean. When fitting the

hose make sure that it is free from twisting, kinks or sharp bends. Protect the hose from any

sharp edges.

2.

Attach one end of the hose to the main shut off valve of city network gas.

3. Do a leak test each time when the gas connection is reconnected. lf the hose shows

deterioration or damage, leak test the entire outer surface.

Remember to turn the city network gas OFF before removing the hose.

Testing for Leaks

1. Ensure knob is OFF and open the cylinder valve.

2. Use a solution of half detergent and half water for leak testing. Brush

solution on each connection and check for bubbles.

3. lf a leak is present, turn off the gas supply at the cylinder or main shut off valve of city

network gas and tighten the loose joint.

4. lf leak persists contact an authorized agent.

INSTALLATION

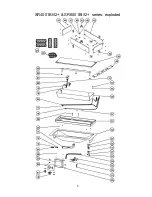

Summary of Contents for SR4001BI/I2+

Page 7: ...6 SR4001BI I2 SR6001BI I2 series exploded...

Page 11: ...10 SR6001BI I2...