35

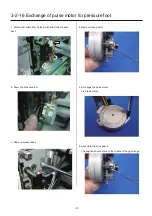

7. Remove take up lever cam.

8. Remove fasten collar.

9. Put good parts back in reverse order.

For adjustment of fixing of each unit, please refer to

process to adjust fixing of each unit.

<Important>

Pay attention to following (1) - (4)

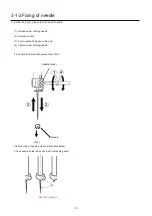

(1)Install upper shaft collar, upper pulley, drive pulley and

crank on flat surface of upper shaft with screw tightly.

(2)Make sure that pulleys and collars are attached

without space from machine body except upper pulley.

(3)Position of upper pulley is space from upper

shaft

collar.

Type of small

collar

Thickness gauge [

11.5mm

]

(4)Confirm that belt is not interfere the pulley flange and

not come out from pulley groove.

Adjustment will be done with following pulley.

Timing belt has to be adjusted with upper pulley position.

Motor belt has to be adjusted with motor pulley position.

10. Please check and adjust the following timing to finish.

[ 4-2-1 Upper shaft timing (L point, C point) ]

[ 3-2-8 Take-up lever timing ]

[ 3-5-1 Rotary hook timing ]

[ 3-6-5 Thread cut timing (except (for Rev.A) ))

Summary of Contents for HCS2-1201-30

Page 1: ...Maintenance Manual for Embroidery Machine HCS2 1201 30 Version 2 3 HappyJapan Inc...

Page 154: ...153 5 1 1 Electrical connection diagram except for Rev A...

Page 155: ...154 5 1 1 Electrical connection diagram except for Rev A...

Page 156: ...155 5 1 2 List of electrical connection diagrams except for Rev A...

Page 157: ...156 5 1 3 Electrical connection diagram for Rev A...

Page 158: ...157 5 1 3 Electrical connection diagram for Rev A...

Page 159: ...158 5 1 4 List of electrical connection diagrams for Rev A...

Page 160: ...159 5 2 1 Connection of inverter 100V Inverter set...

Page 161: ...160 5 2 2 Connection of inverter 200V Inverter set...

Page 165: ...160c HCD8116 TP switch board ass y 6 5 265 2 1 6 7 257...