53

3-2-20

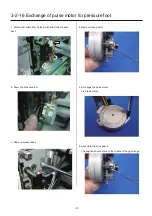

Disassembling and Cleaning of jump solenoid

1. Disassemble the solenoid nut.

Use rubber sheet as safeguard.

2. Clean up the each part of the solenoid.

3. Put the designated grease on plunger part.

<Grease> Shell Grease7 MIL-G-23827B

Equivalent brand.

4. Assemble the solenoid to the original position.

The flat surface of the solenoid nut

should come to the front.

Solenoid cable should come to the back side.

Front face

5. Confirm the movement of the plunger is smooth enough.

6. Procedure is done after assembling the Jump solenoid.

Referring to [3-2-5 Adjustment of fixing of jump solenoid].

Summary of Contents for HCS2-1201-30

Page 1: ...Maintenance Manual for Embroidery Machine HCS2 1201 30 Version 2 3 HappyJapan Inc...

Page 154: ...153 5 1 1 Electrical connection diagram except for Rev A...

Page 155: ...154 5 1 1 Electrical connection diagram except for Rev A...

Page 156: ...155 5 1 2 List of electrical connection diagrams except for Rev A...

Page 157: ...156 5 1 3 Electrical connection diagram for Rev A...

Page 158: ...157 5 1 3 Electrical connection diagram for Rev A...

Page 159: ...158 5 1 4 List of electrical connection diagrams for Rev A...

Page 160: ...159 5 2 1 Connection of inverter 100V Inverter set...

Page 161: ...160 5 2 2 Connection of inverter 200V Inverter set...

Page 165: ...160c HCD8116 TP switch board ass y 6 5 265 2 1 6 7 257...