112

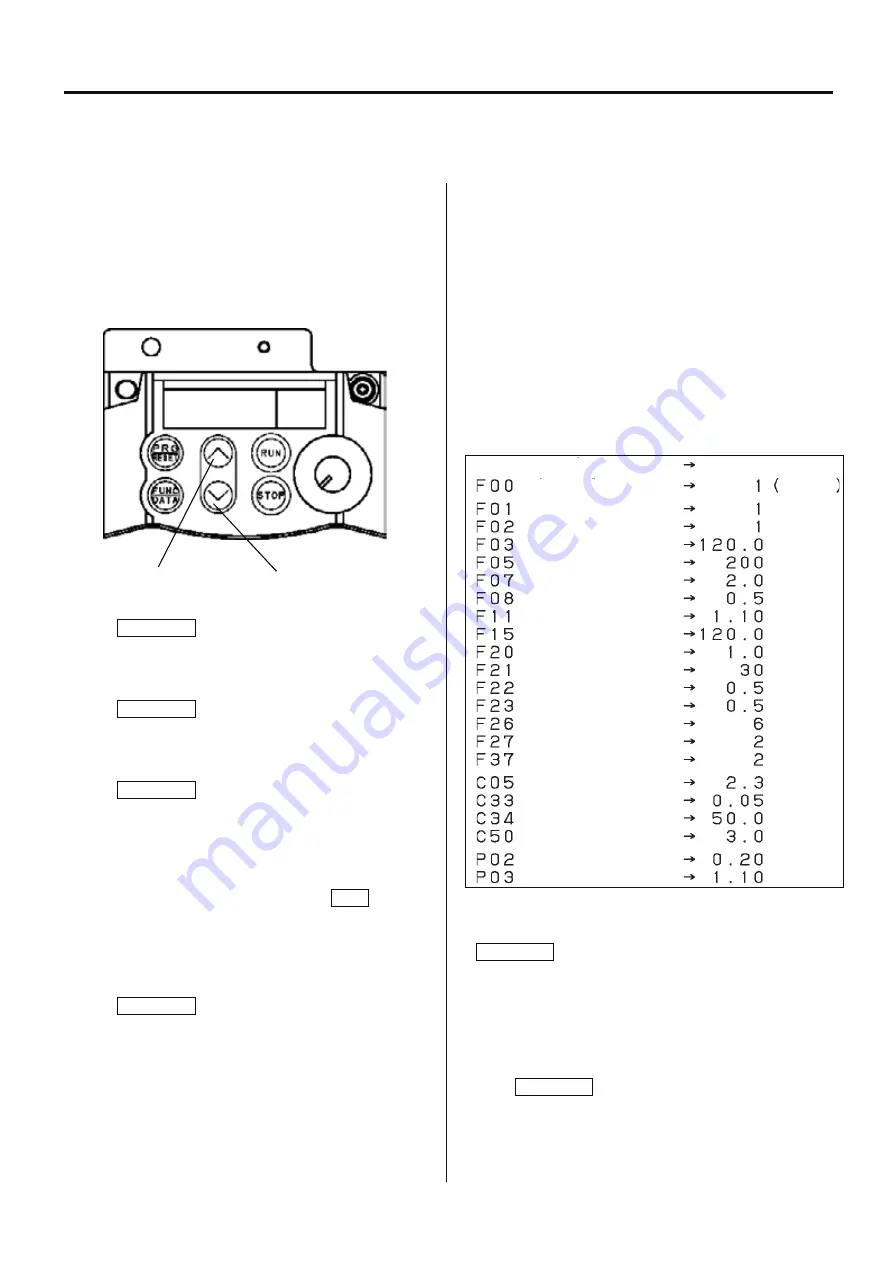

Prohibition of change

Frequency set mode

Drive / Operation

Maxmum frequency

Base frequency volteage

Acceleration time 1

Deceleration time1

Motor thermal protection

Upper limit freq. limter

DC brake. starting freq.

DC braking current

DC braking time

Start frequency

Carrier frequency

Tone

Load selection

Multi stage frequency 1

Analog input filter

Analog input adjustment

Bias frequency

Motor capacity

Motor rated current

Code Function

Setting

Protect

6-2-1 How to set inverter

In case of spare parts supply, parameter is preset. Please contact HAPPY, when you need to change it.

Parameter cannot be set while machine is running .

Pay attention to electric wires as setting is done with power is on.

How to release the setting change prohibition

Release the prohibition by following the procedures below

since parameter is set as setting change prohibition.

1. Press PRG/RESET.

[ I.F _ _ ] is displayed.

2. Press FUNC/DATA.

[ F 0 0 ] is displayed.

3. Press FUNC/DATA again.

[ 1 ] is blinking.

(This means setting change is prohibited.)

4. Press Up key or Down key while pressing STOP.

[ 0 ] is blinking.

(This means you can change settings.)

5. Press FUNC/DATA.

After [SAVE] is indicated,

[ F 0 1 ] is displayed.

By above process, you will be able to set parameters.

Next, change each setting.

6. Press Up key and function code is displayed. Select the

function code whose parameter you would like to change.

(Press Down key and the function code returns to the

previous code.)

The following table shows function codes, setting details, and

factory default setting. Functions other than described below

are initial setting of inverter.

Refer to the next clause for the method of initial setting.

7. Select the code you would like to change and press

FUNK/DATA.

Parameter of the function is displayed.

8. Change parameter by pressing Up or Down key.

9.

Press

FUNK/DATA.

After [SAVE] is displayed, the next function code is displayed.

This means change of the function code is made.

Up key

Down key

Summary of Contents for HCD2-1501-40

Page 1: ...Maintenance Manual for Embroidery Machine HCD2 1501 40 Version 2 3 HappyJapan Inc ...

Page 10: ...10 HSA90311 Shell alvania EP Grease2 100g Page 31 33 36 M0404342 Needle height gauge Page 52 ...

Page 150: ...143 10 1 Electrical connection diagram before Rev A for LCD CE board 1 3 ...

Page 151: ...144 10 1 Electrical connection diagram before Rev A for LCD CE board 2 3 ...

Page 152: ...145 10 1 Electrical connection diagram before Rev A for LCD CE board 3 3 ...

Page 153: ...146 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 1 4 ...

Page 154: ...147 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 2 4 ...

Page 155: ...148 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 3 4 ...

Page 156: ...149 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 4 4 ...

Page 157: ...149a 10 2a Electrical connection diagram Rev A 1 4 ...

Page 158: ...149b 10 2a Electrical connection diagram Rev A 2 4 ...

Page 159: ...149c 10 2a Electrical connection diagram Rev A 3 4 ...

Page 160: ...149d 10 2a Electrical connection diagram Rev A 4 4 ...

Page 161: ...150 10 3 Connection of inverter Inverter set Inverter set ...

Page 165: ...153 HCD8116 TP SW Circuit Board Ass y HCD8124 TC8 7 Circuit Board Ass y Rev A ...

Page 166: ...154 HCD8119 y ...