123

8-2 Machine Test Machine movement

Below operation will be moved solely. In some operations, actuator of motor will be moved, Keep hands and face away during

movement for your own safety.

#

1 Needle Adjust : Input of Needle bar detect Potentiometer

At section of [Setting to detect needle position], this

function can be used to set position of Potentiometer.

#2 Cutter Adjust : Action test of moving knife Open-Close

Use this function to adjust stop position of Moving knife.

#3 Catcher Adjust : Action test of Thread catch hook

This test is used to adjust stop position of Thread catch

hook.

#4 Keeper Test : Action test of Keeper solenoid ON-OFF

This test is used to check action of Keeper.

#5 Jump Solenoid Test : Movement test of jump device

ON-OFF.

This test is used to check movement of Jump device.

#6 Catcher Test : Movement test of thread catch hook

IN-OUT

Use this test to check movement of Thread catch hook.

#7 Cutter Test : Action test of moving knife Open-Close

Use this function to check opening-closing action of

Moving knife.

#8 Clip Solenoid : Action test of clip type thread holder

(Option)

This test is used to check movement of clip type thread

holder.

#9 Pointer Test : Action test of laser pointer (Option)

This test is used to check action of Laser pointer.

#10 Fan Drive Test : Action test of cooling fan ON-OFF

Use this function to check movement of cooling fan.

#11 Encoder Check : Input test of L point / C point timing

With turning main shaft, you can use this function to

check if L point signal, C point signal, and timing signal

are correct or not.

#12 Position Data Entry : Position Data Entry Confirm frame

moving sensor

This test is used to check action of Frame moving

sensor.

From Main program Ver.*1.34~, the Pulse motor will be

un-locked when you activate the test, then you can

move the embroidery frame to your desire position.

#13 Position Data Entry : Confirm registration of frame

position data

You can use this function to check if Frame position data

are entered correctly.

#14 Shaft Drive Test : Main shaft control test

You can turn main shaft with pushing “Start” or “Jump”

key of Needle bar section.

This function can be used for test run after maintenance

work.

#15 Sequin test (Option)

This test is used to check or adjust of Sequin device.

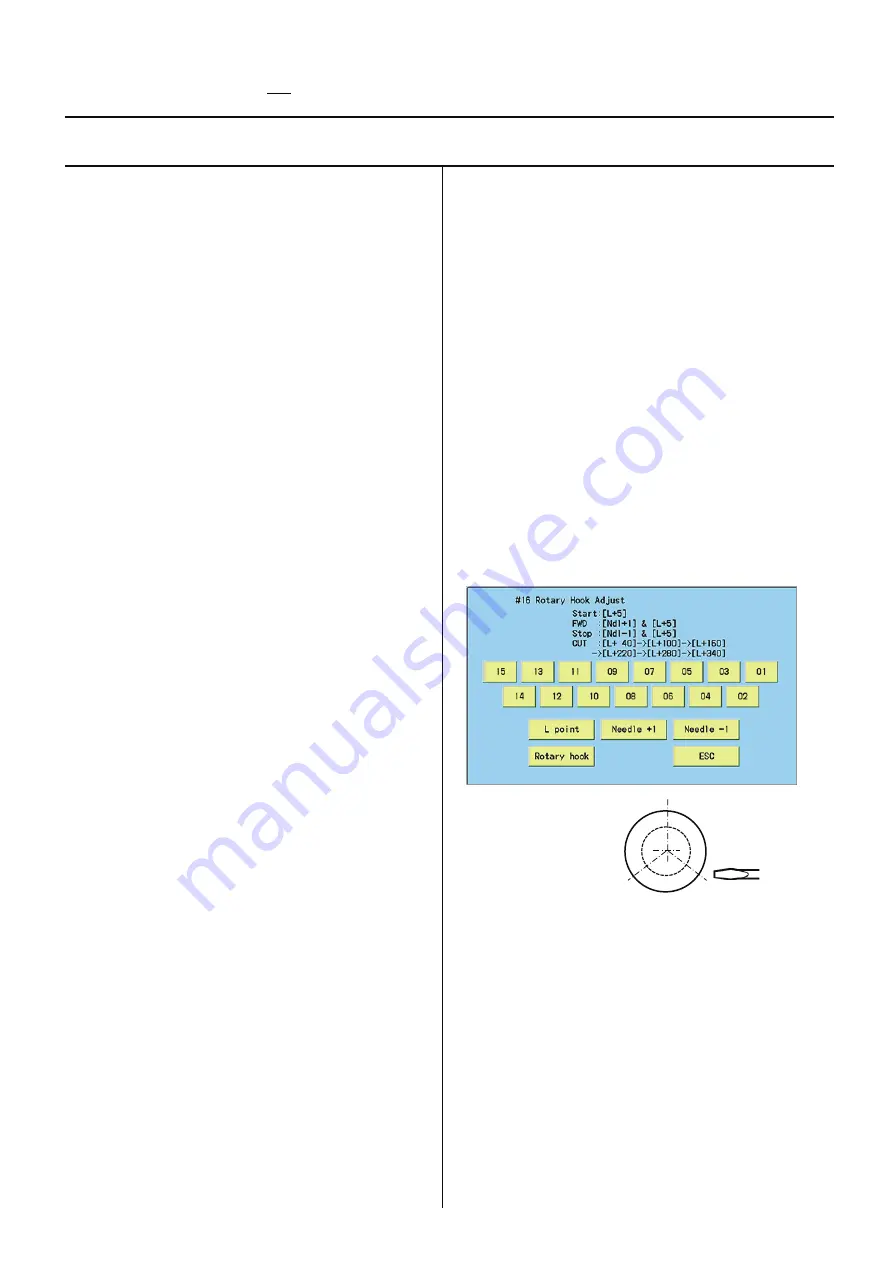

#16 Rotary Hook Adjust

(

Main program Ver.*1.37~

)

This function can be used for [Adjustment of

needle height] or [Adjustment of rotary hook

timing].

40, 220 degrees

160, 340 degrees 100, 280 degrees

[01]–[15]: Needle change

[L point]: Main shaft will turn and set Needle bar

position for [Adjustment of needle height] (L+5

degree).

[Rotary hook]: Rotary hook will turn and stop every

120 degrees to access 3 fixing screws easier.

[Ndl +1],[Ndl -1]: Needle bar moves to the left or

right, then sets Needle bar position for

[Adjustment of needle height] (L+5 degree).

#17 Needle Posi. Adjust

(Not used in HCD2)

Summary of Contents for HCD2-1501-40

Page 1: ...Maintenance Manual for Embroidery Machine HCD2 1501 40 Version 2 3 HappyJapan Inc ...

Page 10: ...10 HSA90311 Shell alvania EP Grease2 100g Page 31 33 36 M0404342 Needle height gauge Page 52 ...

Page 150: ...143 10 1 Electrical connection diagram before Rev A for LCD CE board 1 3 ...

Page 151: ...144 10 1 Electrical connection diagram before Rev A for LCD CE board 2 3 ...

Page 152: ...145 10 1 Electrical connection diagram before Rev A for LCD CE board 3 3 ...

Page 153: ...146 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 1 4 ...

Page 154: ...147 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 2 4 ...

Page 155: ...148 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 3 4 ...

Page 156: ...149 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 4 4 ...

Page 157: ...149a 10 2a Electrical connection diagram Rev A 1 4 ...

Page 158: ...149b 10 2a Electrical connection diagram Rev A 2 4 ...

Page 159: ...149c 10 2a Electrical connection diagram Rev A 3 4 ...

Page 160: ...149d 10 2a Electrical connection diagram Rev A 4 4 ...

Page 161: ...150 10 3 Connection of inverter Inverter set Inverter set ...

Page 165: ...153 HCD8116 TP SW Circuit Board Ass y HCD8124 TC8 7 Circuit Board Ass y Rev A ...

Page 166: ...154 HCD8119 y ...