171

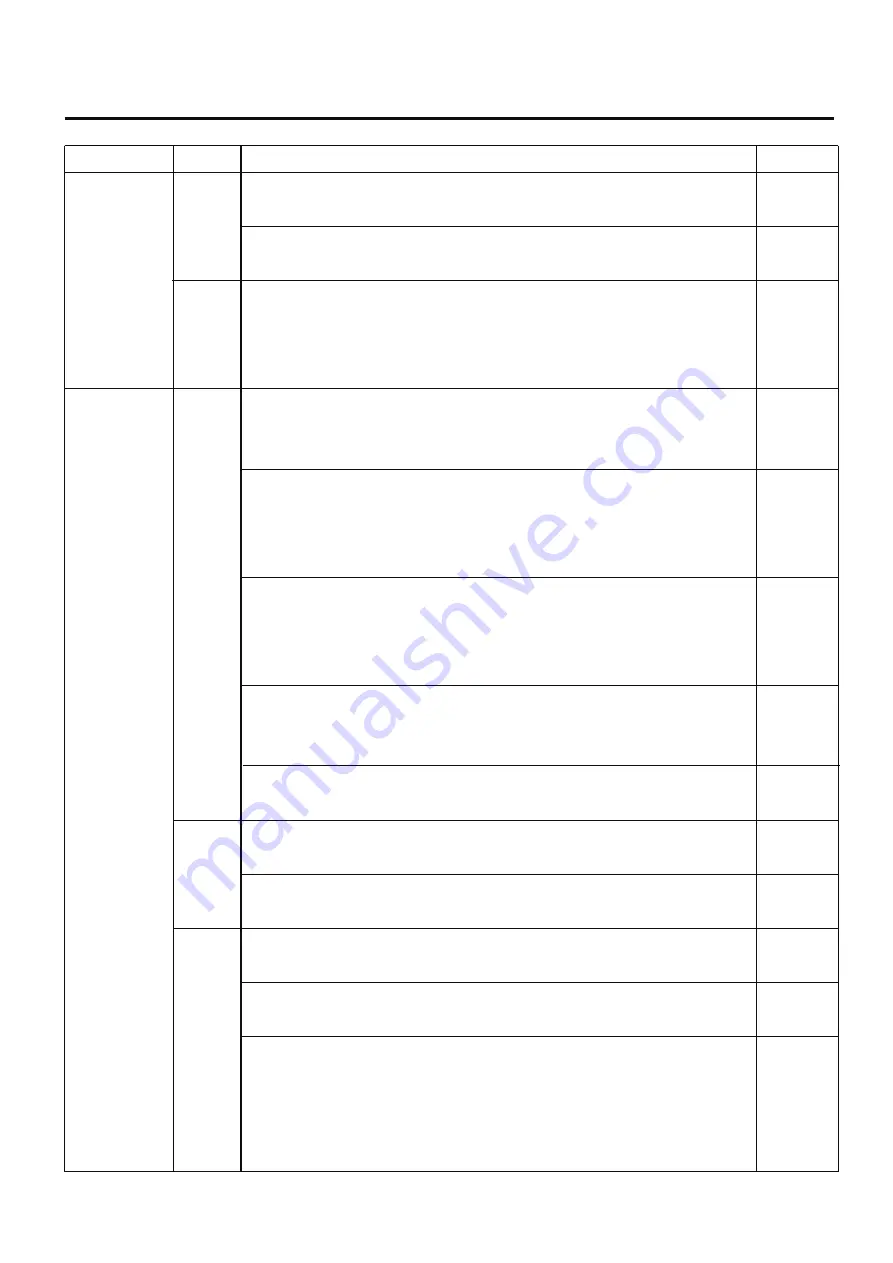

11-2-6 Trouble shooting (Upper thread remains)

Trouble Factor Cause of trouble and measure

Page

Environment

1. Does wind let thread go beyond control? (outside wind, heater, and fan etc.)

1-1 Keep the embroidery machine off from wind.

2. Is voltage of power as rated and stable?

2-1 Supply rated voltage. (23-1)

Upper thread Pattern 1. Is there stop sewing stitch for start sewing?

comes off 1-1 Modify pattern.

from needle

hole

Upper thread

Mechanical

1.

Upper thread is difficult to come out of keeper at time of thread cut (bent or warp etc.).

remains 1-1 Modify bent or warp.

1-2 Replace keeper.

2. Keeper doesn't return properly at time of thread cut.

2-1 Modify bent of keeper.

2-2 Adjust position to fix.

3-6-8

2-3 Adjust it again if movement is not smooth.

3. Upper thread does not come off from magic tape of thread holder.

3-1 Insert something(Thickness 0.1-0.2mm) into holder then move it right and

left to put magic tape in order.

3-2 Replacement of magic tape. 3-3-11

4. Doesn't thread catch hook cut upper thread?

4-1 Polish burr on hook.

4-2 In case hook is in trouble, replace.

5. Isn't rubbing of fixed knife and moving knife weak?

5-1 Adjust to be able to rub properly.

3-6-4

Operator 1. Setting of thread tension is weak.

(4-5) (8-1)

1-1 Strengthen so as not to cause trouble in sewing rhythm.

2. Is [Machine settings] properly set?

(5-1)

2-1 Select setting of length of TRD. cut [Normal].

Thread &

1. Using hard cloth make thread difficult to go through.

cloth 1-1 Select needle and thread.

3-1-4

2. Using thick cloth make thread difficult to go through.

2-1 Select needle and thread.

3-1-4

3. Is thread used to suit embroidery? (thread twist, tender thread).

3-1-3

3-1 Don't use too strongly twisted thread.

3-2 Twist of thread is to be left-wise.

3-3 Use tender thread.

3-4 Don't use thread with knot or uneven size.

( ) ----- Reference instruction book

Summary of Contents for HCD2-1501-40

Page 1: ...Maintenance Manual for Embroidery Machine HCD2 1501 40 Version 2 3 HappyJapan Inc ...

Page 10: ...10 HSA90311 Shell alvania EP Grease2 100g Page 31 33 36 M0404342 Needle height gauge Page 52 ...

Page 150: ...143 10 1 Electrical connection diagram before Rev A for LCD CE board 1 3 ...

Page 151: ...144 10 1 Electrical connection diagram before Rev A for LCD CE board 2 3 ...

Page 152: ...145 10 1 Electrical connection diagram before Rev A for LCD CE board 3 3 ...

Page 153: ...146 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 1 4 ...

Page 154: ...147 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 2 4 ...

Page 155: ...148 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 3 4 ...

Page 156: ...149 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 4 4 ...

Page 157: ...149a 10 2a Electrical connection diagram Rev A 1 4 ...

Page 158: ...149b 10 2a Electrical connection diagram Rev A 2 4 ...

Page 159: ...149c 10 2a Electrical connection diagram Rev A 3 4 ...

Page 160: ...149d 10 2a Electrical connection diagram Rev A 4 4 ...

Page 161: ...150 10 3 Connection of inverter Inverter set Inverter set ...

Page 165: ...153 HCD8116 TP SW Circuit Board Ass y HCD8124 TC8 7 Circuit Board Ass y Rev A ...

Page 166: ...154 HCD8119 y ...