179

11-3-

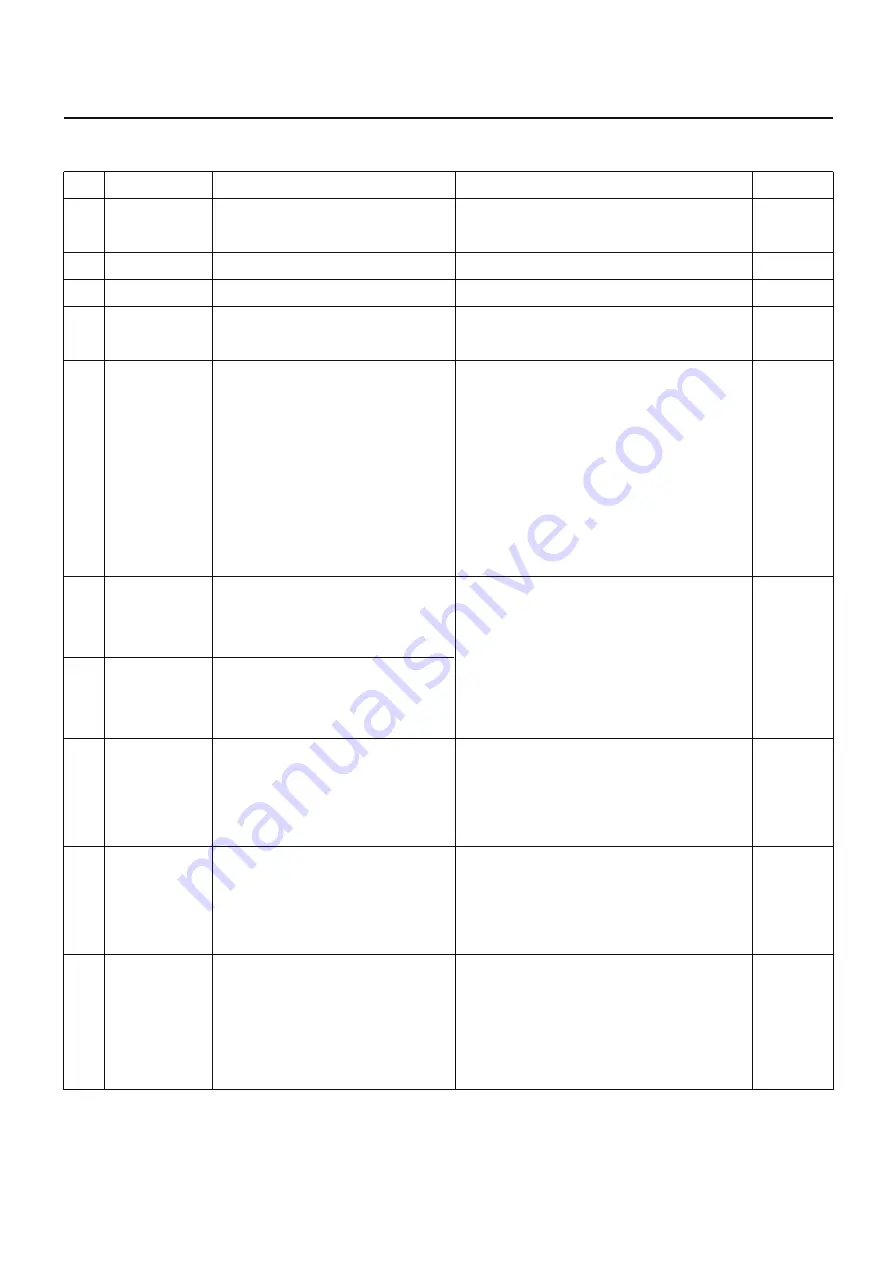

Error and measure

When trouble occurred while the machine is running, error number and error item will be displayed. After confirming contents,

press button [SET] on control box to release error, then restore in accordance with measure in this list.

No. Message Error Measure Page

001 Circuit board

Trouble detected in control circuit board. (1)Turn power off once and turn on again.

(2)If recurred, replace LCD-CE board.

002 Power source Power failure or abnormal voltage Replace LCD-CE board.

004 System memory Trouble in system memory. Replace LCD-CE board.

014 Fan Alarm Cooling fan on CONT-D2 board fault (1)Clean dust attached to fan.

(2)Replace fan. 4-4

015 Inverter trip Trouble in drive unit on main shaft.

(1)Turn power off, turn main shaft by hand and

Overload on main shaft motor, if no trouble found, turn power on again.

damage in drive unit on main shaft.

(2)If trouble found, repair where damaged.

(3)If inverter in trouble, replace. 6-1-1

(4)Check if voltage high or not. If high,check

origin of power source of factory.

Or use stabilizer, transformer to set to

rated voltage.

016 Alarm X unit X-motor-related trouble, i.e. x-motor (1)Power off machine, test pantograph

overload, short circuit, problem with movement manually. Check for any

motor drive unit abnormality throughout full range of motion.

017 Alarm X unit Y-motor-related trouble, i.e. y-motor If none found, power on again.

overload, short circuit, problem with (2)Check related harnes.

(3)Replace drive-A circuit board. 4-2

018 Main shaft Suspension of main shaft in mid way. (1)Check if trouble found between main shaft

and drive. If trouble found, restore.

(2)If recurred, find cause and fix.

(3)Make automatic speed setting again.

7-4

020 Needle detect Needle position not detected.

(1)Turn needle selection cam by hand to set to

Trouble in stop position of needle

regular position

.

selection unit.

(2)Fix needle selection related mechanical trouble.

(3)

Replace sensor circuit board or potentiometer.

3-4-2

021 Needle move Suspension of needle selection motor (1)Turn needle selection cam by hand to set to

022 in mid way. regular position.

Trouble in take-up lever hinders.

(2)

Fix needle selection related and take up lever

Trouble in position detecting circuit related troubles.

board.

(3)

Replace sensor circuit board or potentiometer.

3-4-2

( ) ----- Reference instruction book

Summary of Contents for HCD2-1501-40

Page 1: ...Maintenance Manual for Embroidery Machine HCD2 1501 40 Version 2 3 HappyJapan Inc ...

Page 10: ...10 HSA90311 Shell alvania EP Grease2 100g Page 31 33 36 M0404342 Needle height gauge Page 52 ...

Page 150: ...143 10 1 Electrical connection diagram before Rev A for LCD CE board 1 3 ...

Page 151: ...144 10 1 Electrical connection diagram before Rev A for LCD CE board 2 3 ...

Page 152: ...145 10 1 Electrical connection diagram before Rev A for LCD CE board 3 3 ...

Page 153: ...146 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 1 4 ...

Page 154: ...147 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 2 4 ...

Page 155: ...148 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 3 4 ...

Page 156: ...149 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 4 4 ...

Page 157: ...149a 10 2a Electrical connection diagram Rev A 1 4 ...

Page 158: ...149b 10 2a Electrical connection diagram Rev A 2 4 ...

Page 159: ...149c 10 2a Electrical connection diagram Rev A 3 4 ...

Page 160: ...149d 10 2a Electrical connection diagram Rev A 4 4 ...

Page 161: ...150 10 3 Connection of inverter Inverter set Inverter set ...

Page 165: ...153 HCD8116 TP SW Circuit Board Ass y HCD8124 TC8 7 Circuit Board Ass y Rev A ...

Page 166: ...154 HCD8119 y ...