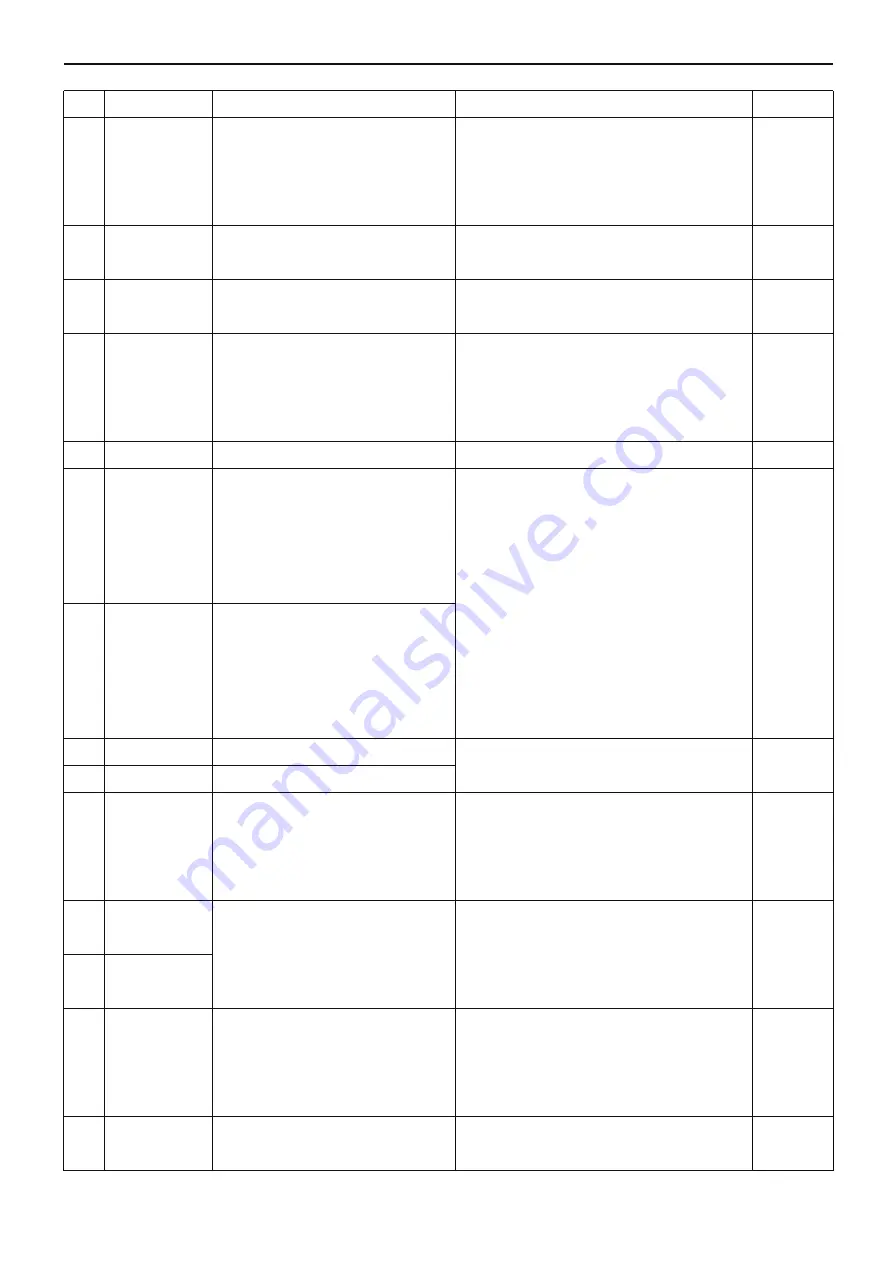

180

No. message Error measure page

024 Needle center Stop position of needle bar is off center

(1)Turn needle selection cam by hand to set to

regular position.

(2)If trouble occurs repeatedly, fix mechanical

trouble in needle selection & its vicinity.

025 Needle over Specified needle number went beyond Adjust position of needle selection cam (poten-

needle number of the machine. tiometer) and needle number of moving head.

3-4-3

026 Needle differ

As needle number differed from memory

(1)Turn power off once and turn on again.

when power turned on, it was renewed.

(2)

Let the machine recognize needle number.

3-4-3

030 Slow mismatch Inadequate adjustment of number of

(1)Make automatic speed setting.

7-4

low speed revolution.

(2)If not solved even after speed adjustment, 5-2

Low speed revolution doesn't come replace LCD-CE board.

below 100rpm.

050 C point Main shaft stops off its position.

(1)

Turn main shaft to plus direction to set to C point.

(24-1)

051 L sensor Poor lowest needle position sensor

(1)If photo sensor is stained, clean.

3-8-4

on timing detecting circuit board.

(2)Adjust timing.

Damage in timing detecting circuit

(3)Replace main shaft timing circuit board.

board, stained photo sensor, poor

adjustment of slit disc.

052 C sensor

Damage in color change point

sensor on timing circuit board.

Damage in timing detecting circuit

board, stained photo sensor, poor

adjustment of slit disc.

060 X limit

Drive frame went beyond limits in X direction.

(1)Move drive frame back to limits with move key.

061 Y limit

Drive frame went beyond limits in Y direction.

(2)Correct pattern size and setting contents.

063 Drive Setup During embroidery, preparation for (1) Malfunction of "Lowest needle position" 3-8-3

frame movement did not complete sensor on detection circuit board, Improper

within predetermined time. adjustment.

(2) Make automatic speed setting. 7-4

064 X Center sens. Trouble in embroidery frame sensor (1) Check if position sensor is dirty. 3-7-5

Turn off power source, then turn on again. 3-7-6

065 Y Center sens. (2) Setup mistake of the machine parameter 8-5

(3) Replace position sensor circuit board.

066 Frame drive

Frame movement did not complete

(1) Dirt L point sensor [PH1] or wrong position 3-8-4

during origin point movement. of slit.

(2) Dirt timing slit, position adjustment 3-8-3

(3)Replace timing circuit board. 3-8-3

067 L sensor Consumption of embroidery frame Adjust position sensor position on carriage. 8-6

coordinate data. Then register frame position again.

( ) ----- Reference instruction book

Summary of Contents for HCD2-1501-40

Page 1: ...Maintenance Manual for Embroidery Machine HCD2 1501 40 Version 2 3 HappyJapan Inc ...

Page 10: ...10 HSA90311 Shell alvania EP Grease2 100g Page 31 33 36 M0404342 Needle height gauge Page 52 ...

Page 150: ...143 10 1 Electrical connection diagram before Rev A for LCD CE board 1 3 ...

Page 151: ...144 10 1 Electrical connection diagram before Rev A for LCD CE board 2 3 ...

Page 152: ...145 10 1 Electrical connection diagram before Rev A for LCD CE board 3 3 ...

Page 153: ...146 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 1 4 ...

Page 154: ...147 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 2 4 ...

Page 155: ...148 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 3 4 ...

Page 156: ...149 10 2 Electrical connection diagram before Rev A for LCD CE U LCD CE MX board 4 4 ...

Page 157: ...149a 10 2a Electrical connection diagram Rev A 1 4 ...

Page 158: ...149b 10 2a Electrical connection diagram Rev A 2 4 ...

Page 159: ...149c 10 2a Electrical connection diagram Rev A 3 4 ...

Page 160: ...149d 10 2a Electrical connection diagram Rev A 4 4 ...

Page 161: ...150 10 3 Connection of inverter Inverter set Inverter set ...

Page 165: ...153 HCD8116 TP SW Circuit Board Ass y HCD8124 TC8 7 Circuit Board Ass y Rev A ...

Page 166: ...154 HCD8119 y ...