1

23

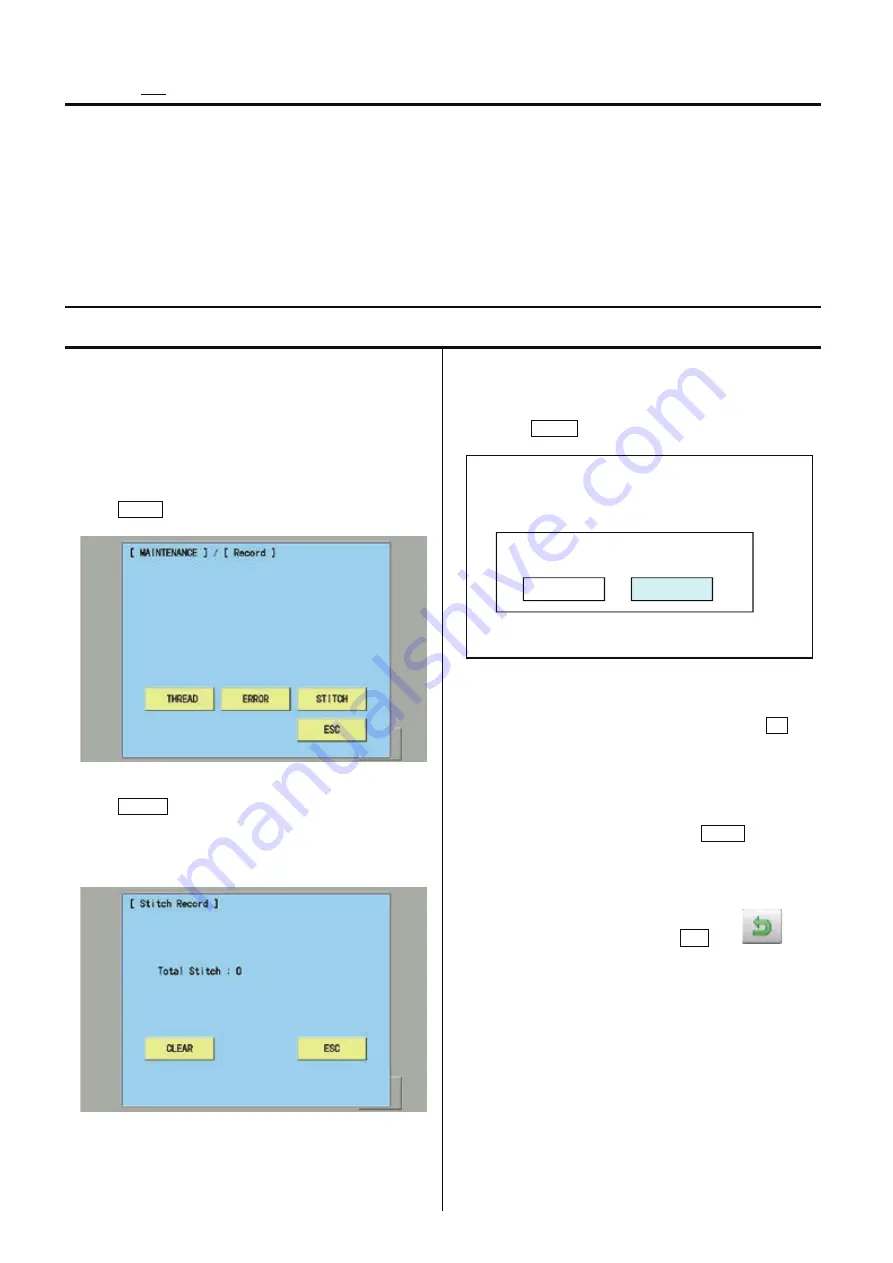

Record Operation data display

4-4-4

You can confirm history of operation.

Total number of stitch

: Total number of stitch used for embroidery so far

Error occurrence record

: Type of errors and its occurrence date for the last 32 errors

Occurrence record by error type : Accumulated number of each error occurrence

Thread break history

: The number of thread break by needle bar

Total number of stitch

4-4-4-1

1. Enter maintenance mode in reference to [ 9-1 How to enter

maintenance mode ]

2. Press Record.

3. Press STITCH.

The screen shows total number stitches used for

embroidery so far.

4. Selection menu of Clear Total Stitch will be opened when

pressing CLEAR at Procedure 3.

* Total number of stitch is cleared after pressing OK and

the screen shows one in the procedure 3. Total number of

stitch is 0.

* If you do not prefer to clear it, press Cancel and

the screen shows of the procedure 3 is shown

5. Return to drive mode by pressing ESC and

.

Clear Total Stitch ?

Cancel

OK

Summary of Contents for HCH-701-30

Page 1: ...Maintenance Manual for Embroidery Machine HCH 701 30 Version 2 4 HappyJapan Inc ...

Page 132: ...128 Electrical connection diagram 5 ...

Page 133: ...129 Electrical connection diagrams 5 ...

Page 134: ...130 List of electrical connection diagrams 5 ...

Page 137: ...130c HCD81222 LCD CE MX 基板組 ...

Page 138: ...130d HCD8116 TP switch board ass y 3 82 7 32 7 387487 2487 ...