193

Trouble Factor Cause of trouble and measure

Page

Thread break

Environment

4

. Is there something that produce steam, wasted cotton, dust around.

the embroidery machine?

4-1 Keep the embroidery machine off those things.

5. Does thread go out of control by taking wind from outside or heater etc.?

5-1 Keep the embroidery machine off such wind.

5-2 Move the embroidery machine to proper place.

Pattern

1. Does thread break occur repeatedly at same place in design?

1-1 Check pattern to modify punching.

2. Is it too narrow between stitches?

2-1 Check pattern to modify punching.

2-2 Setting of [Reading] menu. (Stitch sweeper)

(10-3 )

3. Too many empty stitches?

3-1 Make [Reading] setting. (Skip null stitches)

( 10-3 )

Others 1. Using spray paste (adhesive material)

1-1 Clean around rotary hook.

( 23-2 )

1-2 Replace or clean needle. 3-1

1-3 Use this paste at a given place and never use in front or back of

the embroidery machine.

( ) ----- Reference instruction book

Summary of Contents for HCR3-1502

Page 1: ... Maintenance Manual for Embroidery Machine HCR3E SERIES Version 1 2 HappyJapan Inc ...

Page 104: ...105 4 7 3 Adjustment of timing detecting unit 8 Finally put the cover back on ...

Page 107: ...107 ...

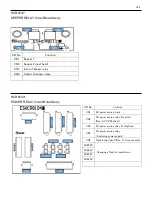

Page 172: ...172 E7 Electric system diagram E7 1 Pulse motor driver PMD wiring ...

Page 173: ...173 E7 2 Pulse motor driver PMD setup ...

Page 174: ...174 E7 3 Inverter wiring ...

Page 175: ...175 E7 4 Electrical connection diagram ...

Page 176: ...176 ...

Page 177: ...177 ...

Page 178: ...178 E7 5 List of electrical connection diagram ...

Page 179: ...179 ...

Page 180: ...180 E7 6 Explanation of function clrcuit board HCD8122 LCD CE MX Board Ass y ...

Page 181: ...181 HCD8116 TP SW Circuit Board Ass y CN No Function CN1 Switch output LED input ...