16

CARE AND MAINTENANCE

TROUBLESHOOTING

At least twice each year, lower canopy to check down rod assembly, and then tighten all screws on

IDQ&OHDQPRWRUKRXVLQJZLWKRQO\DVRIWEUXVKRUOLQWIUHHFORWKWRDYRLGVFUDWFKLQJWKH¿QLVK&OHDQ

blades with a lint-free cloth. You may occasionally apply a light coat of furniture polish to wood blades

for ass protection. Important: Shut off main power supply before beginning and maintenance. Do not

use water or a damp cloth to clean the ceiling fan.

If you have any questions regarding the product, please call customer service at 1-800-643-0067,

8 a.m. - 6 p.m., EST, Monday - Thursday, 8 a.m. - 5 p.m., EST, Friday.

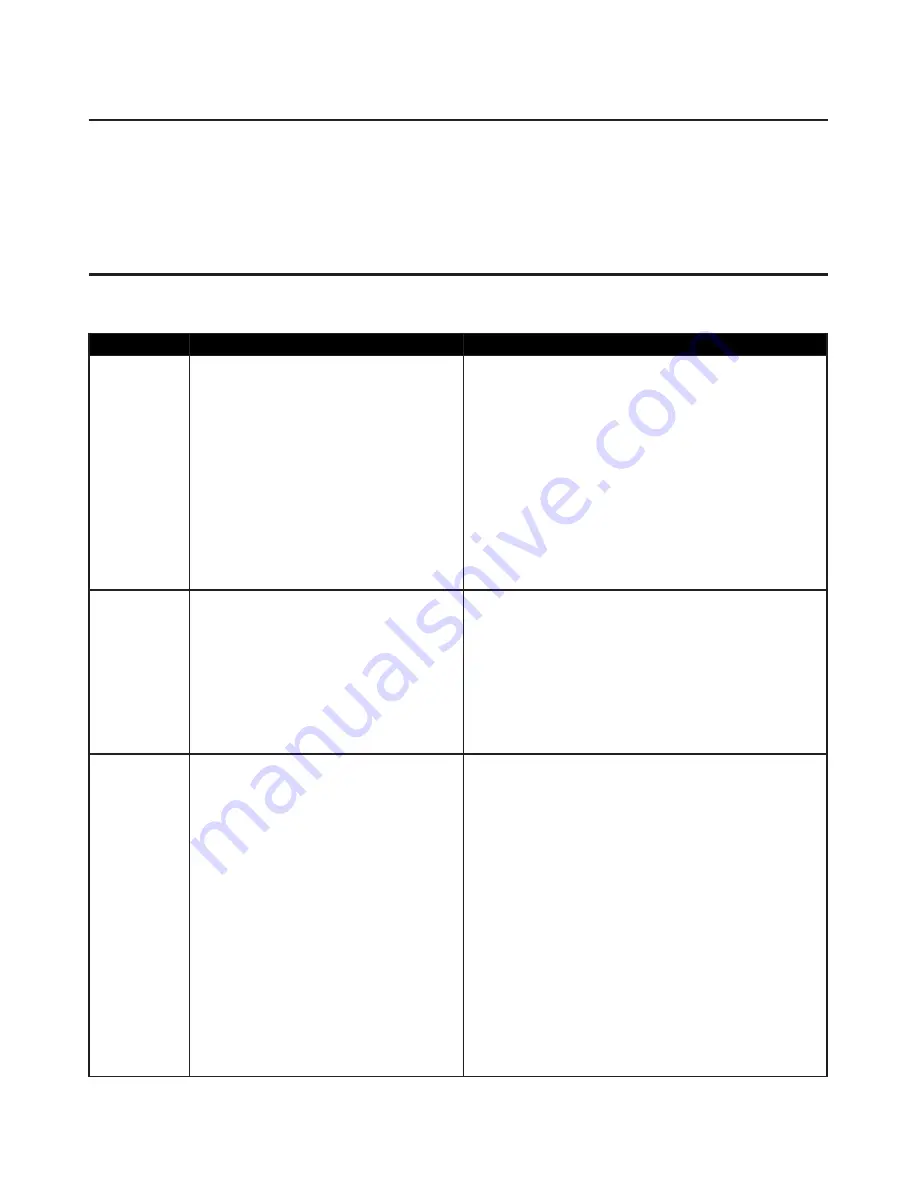

PROBLEM

Fan does

not move.

Noisy

operation

Excessive

wobbling

QUANTITY

1. Turn power on or check fuse.

2. Turn power off. Loosen canopy and check

all connections.

3. Check that the connectors from the light kit

¿WWHUDQGIDQDUHFRQQHFWHGDFFRUGLQJWR

instructions on page 13.

4. Disable power supply to the fan motor and

re-start.

5. The blade is overweight. Don’t install the

unapproved blades.

1. Tighten all blade screws.

2. Replace blade.

3. Replace with an approved speed control

device.

4. Allow fan a “break in” period of a few days,

especially when running the fan at Medium

and High speeds.

1. Tighten all blade screws.

2. Re-install blade arms.

3. Switch one blade with a blade from the

opposite side.

4. Turn power off. Carefully loosen canopy and

verify that mounting bracket is secure.

5. Use a longer down rod or move fan to

another location.

6. Tighten yoke set screw securely.

7. Carefully loosen and lower canopy and

verify that set screw on hanging ball is

tightened securely.

DESCRIPTION

1. Power is off or fuse is blown.

2. Faulty wire connection.

3. Plugs not connected properly.

4. DC motor is obstructed during

operation.

5. The power of motor over 80W.

1. Blades are loose.

2. Cracked blade.

3. Full range dimmer switch.

4. Fan is new.

1. Blades are loose.

2. Blade arms incorrectly attached.

3. Unbalanced blades.

4. Fan not securely mounted.

5. Fan too close to vaulted ceiling.

6. Set screw on motor housing

yoke is(are) not tightened

properly.

7. Set screw on hanging ball is not

tightened properly.