J

Molex

Connections

L

L

13

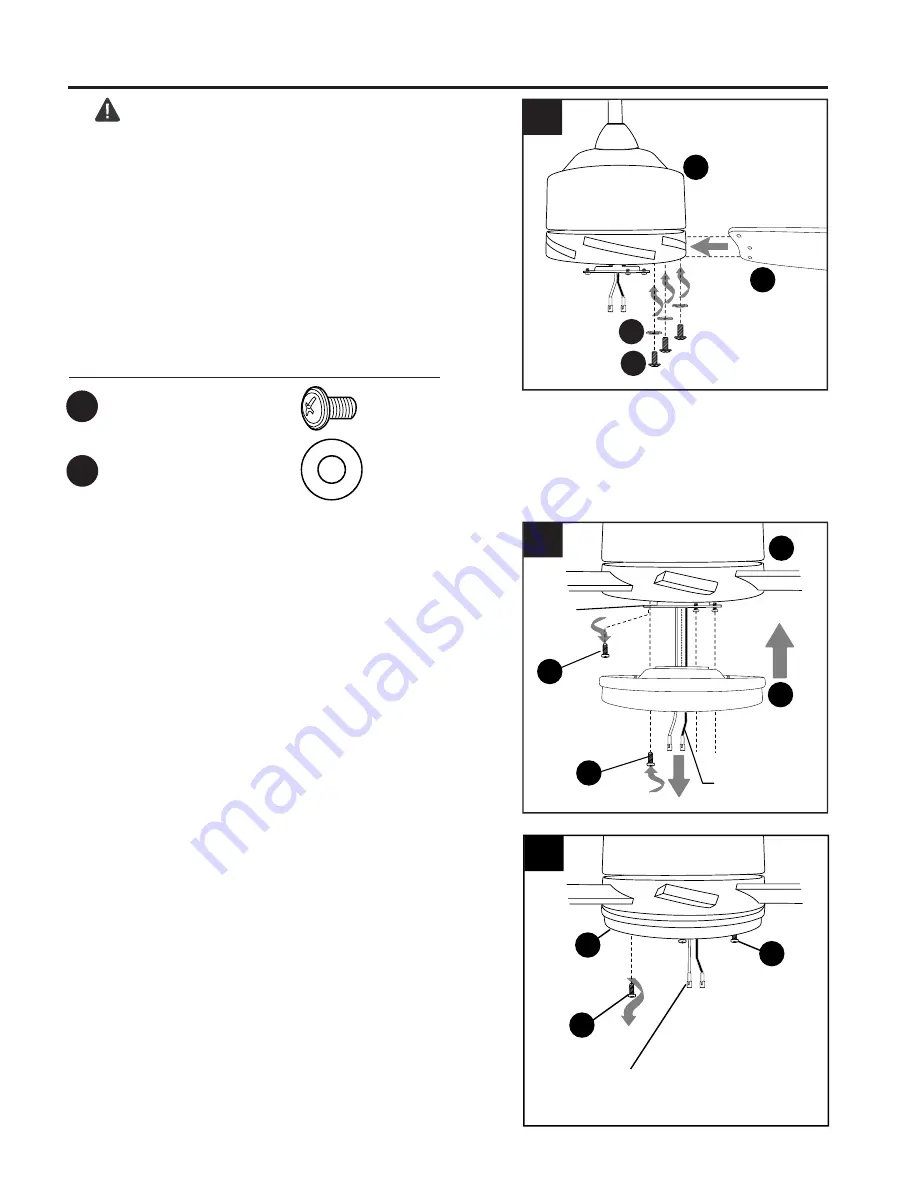

FINAL INSTALLATION

2.

Hardware Used

AA

Blade Screw x 21

Fiber Blade Washer x 21

BB

DANGER:

To reduce the risk of serious bodily

injury,

DO NOT use power tools to assemble the

blades (O). If screws are overtightened, blades

(O) may crack and break.

Insert the blade (O) through the slot on the band

of the motor housing (I). Align holes in blade (O)

with holes on underside of motor. Attach the blade

(O) with blade screws (AA) and fiber blade

washers (BB). Then, tighten each blade screw

(AA), starting with the one in the middle. Repeat

for remaining blades (O).

4.

3.

3

2

BB

Remove one fitter plate screw (L) from underside

of fitter plate (J) and partially loosen the other two

fitter plate screws (L).

3

Motor

Plate

Molex

Connections

IO

I

4

IK

Remove one motor plate screw (K) from motor

plate on underside of motor housing (I) and

partially loosen the other two motor plate screws

(K). Align slotted holes in fitter plate (J) with

loosened motor plate screws (K), allowing molex

connections from motor housing (I) to come

through hole in fitter plate (J). Twist fitter plate (J)

to lock. Re-insert the motor plate screw (K) that

was removed and securely tighten all three motor

plate screws (K).

IK

IJ

AA

I