CARE AND MAINTENANCE

OPERATING INSTRUCTIONS

17

4a

4b

4c

4c.

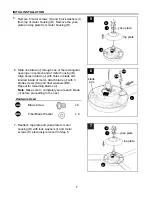

IMPORTANT:

Reverse switch must be set

either

completely

LEFT or

completely

RIGHT for

fan to function. If the reverse switch is set in the

middle position, fan will not operate.

4a. In

warmer

weather, setting the reverse switch

in the LEFT position will result in downward airflow

creating a wind chill effect.

4b. In

cooler

weather, setting the reverse switch

in the RIGHT position will result in upward airflow

that can help move stagnant, hot air off the ceiling

area.

At least twice each year, lower canopy (B) to check downrod (A) assembly, and then tighten all

screws on fan. Clean motor housing (D) with only a soft brush or lint-free cloth to avoid scratching the

finish. Clean blades (J) with a lint-free cloth. You may occasionally apply a light coat of furniture

polish to wood blades for added protection.

IMPORTANT:

Shut off main power supply before beginning any maintenance. Do not use water or a

damp cloth to clean the ceiling fan.