Page 8

For technical questions, please call 1-800-444-3353.

Item 60239

NOTICE

Clean the Spray Gun IMMEDIATELY after use.

Delayed or inadequate cleaning will permanently clog the Spray Gun.

SAFETY

Op

ERA

TION

M

AINTENANCE

SETU

p

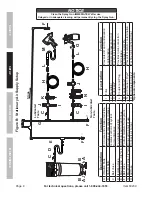

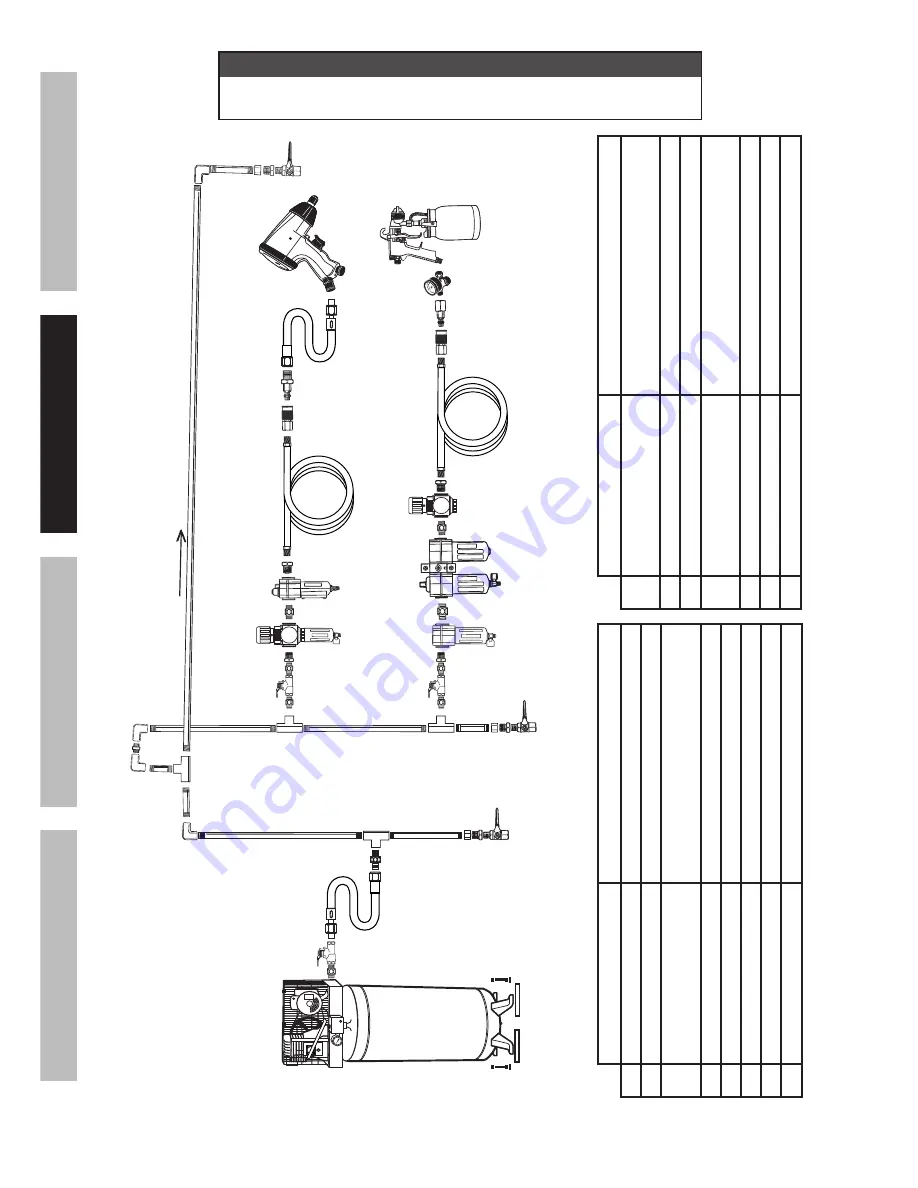

Figure

B:

Stationary

Air Supply Setup

N

L

L

O

M

C

C

Non-lubricated Tools

Lubricated Tools

H

I

I

J

J

K

H

F

G

E

Slope

F

F

B

B

A

A

C

D

Description

Function

A

Vibration Pads

For noise and vibration reduction

B

Anchor Bolts

Secures air compressor in place

C

Ball V

alve

Isolates sections of system for maintenance

D

Isolation Hose

For vibration reduction

E

Main

Air Line - 3/4″ min.

Distributes air to branch lines

F

Ball V

alve

To drain moisture from system

G

Branch

Air

Line

-1/2″

min.

Brings air to point of use

H

Air Hose

Connects air to tool

Description

Function

I

Filter

Prevents dirt and condensation contamination

J

Regulator

Adjusts air pressure to tool

K

Lubricator

*

For air tool lubrication

L

Coupler and Plug

Provides quick connection and release

M

Leader Hose

*

Increases coupler life

N

Air Cleaner / Dryer

*

Prevents moisture contamination

O

Air Adjusting

Valve

*

For fine tuning airflow at tool

*Optional components.

Summary of Contents for 60239

Page 1: ......