Page 15

For technical questions, please call 1-800-520-0882.

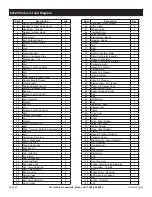

Vertical Engine

Troubleshooting

Problem

Possible Causes

Probable Solutions

Engine will not start MOWER ENGINE SPECIFIC:

1. Brake Handle not held or brake

cable not connected properly.

2. Mower on top of grass.

MOWER ENGINE SPECIFIC:

1. Make sure brake handle is held down

and brake cable is properly adjusted.

2. Start mower atop clear area free

of loose objects and grass.

FUEL RELATED:

1. No fuel in tank.

2. Low quality or deteriorated, old gasoline.

3. Carburetor not primed.

4. Dirty fuel passageways.

5. Carburetor needle stuck. Fuel

can be smelled in the air.

6. Too much fuel in chamber. This can be

caused by the carburetor needle sticking.

FUEL RELATED:

1. Fill fuel tank.

2. Use fresh 87+ octane unleaded gasoline.

3. Press priming bulb before starting cold engine.

4. Clean out passageways using fuel additive.

Heavy deposits may require further cleaning.

5.

Gently

tap side of carburetor float

chamber with screwdriver handle.

6. Turn Choke to RUN (OPEN) position.

Remove spark plug and pull the start

handle several times to air out the chamber.

Reinstall spark plug and set Choke to

CHOKE (START/CLOSED) position.

IGNITION (SPARK) RELATED:

1. Spark plug cap not connected securely.

2. Spark plug electrode wet or dirty.

3. Incorrect spark plug gap.

4. Spark plug cap broken.

5. Incorrect spark timing or

faulty ignition system.

IGNITION (SPARK) RELATED:

1. Connect spark plug cap properly.

2. Clean spark plug.

3. Correct spark plug gap.

4. Replace spark plug cap.

5. Have qualified technician diagnose/

repair ignition system.

COMPRESSION RELATED:

1. Cylinder not lubricated. Problem after long

storage periods.

2. Loose or broken spark plug. (Hissing noise

will occur when trying to start.)

3. Loose cylinder head or damaged

head gasket. (Hissing noise will

occur when trying to start.)

4. Engine valves or tappets

mis-adjusted or stuck.

COMPRESSION RELATED:

1. Pour tablespoon of oil into spark

plug hole. Crank engine a few

times and try to start again.

2. Tighten spark plug. If that does not work,

replace spark plug. If problem persists,

may have head gasket problem, see #3.

3. Tighten head. If that does not remedy

problem, replace head gasket.

4. Have qualified technician diagnose/

repair ignition system.

Follow all safety precautions whenever diagnosing or servicing the equipment or engine.