Page 3

For technical questions, please call 1-800-520-0882.

Vertical Engine

Save This Manual

Keep this manual for the safety warnings and precautions,

assembly, operating, inspection, maintenance and

cleaning procedures. Write the product’s serial

number in the back of the manual near the assembly

diagram (or month and year of purchase if product

has no number). Keep this manual and the receipt

in a safe and dry place for future reference.

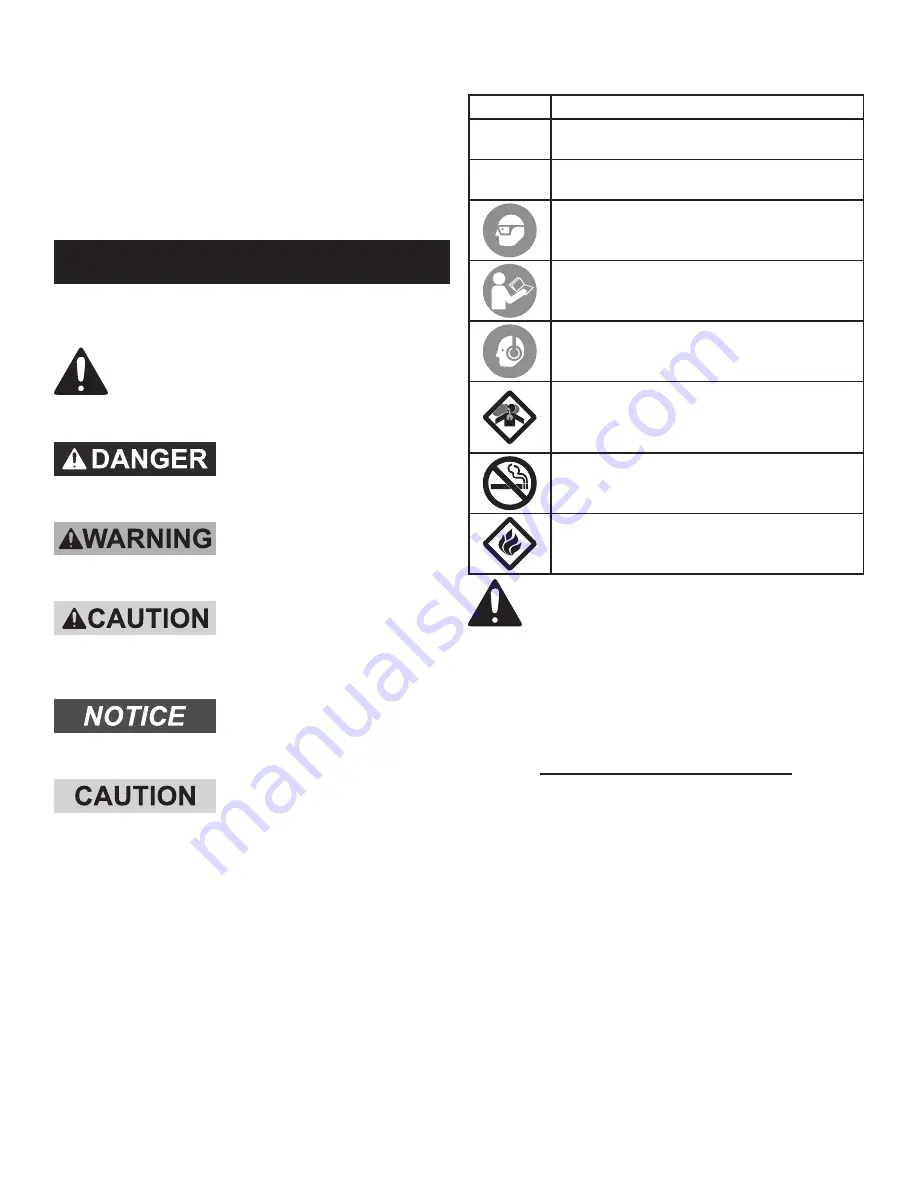

Safety Warnings

In this manual, on the labeling, and all other

information provided with this product:

This is the safety alert symbol. It is used

to alert you to potential personal injury

hazards. Obey all safety messages that

follow this symbol to avoid possible injury

or death.

DANGER indicates a hazardous situation which, if

not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol,

indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE is used to address practices

not related to personal injury.

CAUTION, without the safety alert symbol, is used

to address practices not related to personal injury.

Symbol Definitions

Symbol

Property or Statement

RPM

Revolutions Per Minute

HP

Horsepower

WARNING marking concerning Risk

of Eye Injury. Wear ANSI-approved

safety goggles with side shields.

Read the manual before set-up and/or use.

WARNING marking concerning Risk of

Hearing Loss. Wear hearing protection.

WARNING marking concerning

Risk of Respiratory Injury. Operate

engine OUTSIDE and far away from

windows, doors, and vents.

WARNING marking concerning

Risk of Fire while handling fuel. Do

not smoke while handling fuel.

WARNING marking concerning Risk of Fire.

Do not refuel while operating.

Keep flammable objects away from engine.

WARNING! Read all instructions.

Failure to follow all instructions listed below

may result in fire, serious injury and/or DEATH.

The warnings and precautions discussed in this

manual cannot cover all possible conditions and

situations that may occur. It must be understood

by the operator that common sense and caution

are factors which cannot be built into this

product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS