Page 15

For technical questions, please call 1-888-866-5797.

Items 68285 68284

Sa

FE

ty

Op

E

ra

ti

O

n

Maint

E

nanc

E

S

E

tup

General cleaning, Maintenance, and Lubrication

1.

BEFOrE EacH uSE,

inspect the general

condition of the tool. Check for:

• loose hardware,

• misalignment or binding of moving parts,

• cracked or broken parts,

• damaged electrical wiring, and

• any other condition that may

affect its safe operation.

2.

aFtEr uSE,

wipe external surfaces of

the tool with clean cloth. Store indoors

out of the reach of children.

3.

WarninG! tO prEVEnt SEriOuS

inJury: if the supply cord of this appliance

is damaged, it must be replaced only

by a qualified service technician.

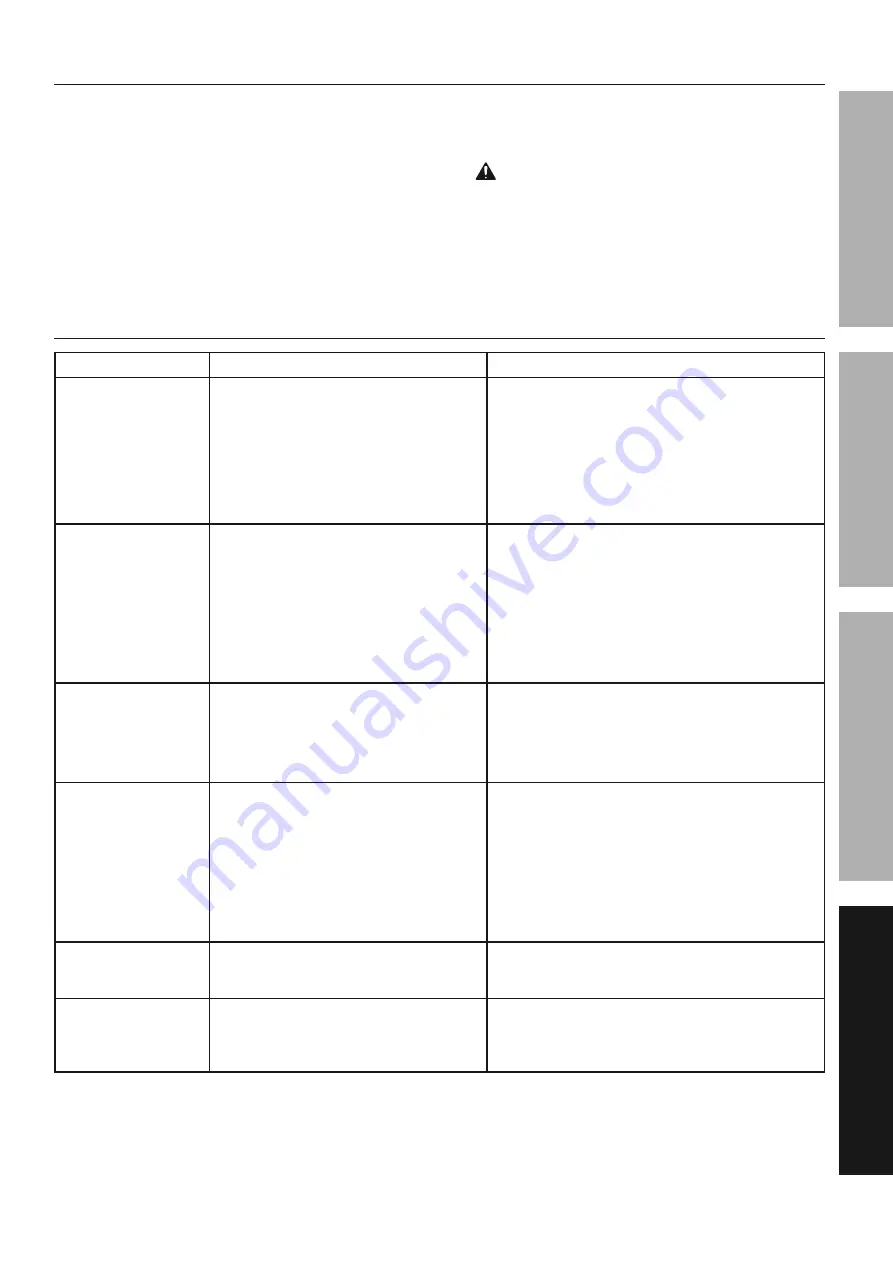

troubleshooting

problem

probable cause(s)

Solution(s)

Motor shuts off

during use.

1. The motor may have been shut off

by its internal thermal protection

switch, or auto reset breaker.

2. GFCI breaker tripped.

1. Turn Rotation Switch to

OFF

. Allow motor to

cool off completely before restarting and stay

clear of cable when turning motor back on.

2. Make sure all electrical components are

dry and all insulation is in good repair.

Press reset button. If GFCI trips again,

have appliance serviced by qualified

electrician before further use.

Cable kinks, twists,

or breaks.

1. 1.

Too much force on the cable.

2. 2.

Too much slack between

Drain Cleaner and drainpipe inlet.

3. 3.

Cable used is wrong size

for drain pipe.

4. 4.

Cable exposed to acid.

5. 5.

Cable worn out.

1. 1.

Do not force cable. Let

Cutting Tool do the work.

2. 2.

Move Drain Cleaner to within

2 feet of drainpipe inlet.

3. 3.

Change cable size.

4. 4.

Clean and oil cable regularly.

5. 5.

Replace cable.

Cable tangles in drum. 1. Too much force on the cable.

2. Motor running in reverse.

3. Distributor tube frozen.

1. Do not force cable. Let Cutting Tool do the work.

2. Retract Cable with the Rotation

Switch in the

FOr

position.

3. Technician should lubricate

distributor tube bearings.

Power Cord GFCI

trips when unit

is plugged in or

when Foot Switch

is pressed.

1. Motor Rotation Switch defective.

2. Frayed Power Cord.

3. Short circuit in Motor.

4. Excess moisture touching

Power Cord or Drain Cleaner.

5. Faulty GFCI unit.

1. Repair or replace Motor Rotation Switch.

2. Have Power Cord replaced by

a qualified technician.

3. Have Motor repaired or replaced

by a qualified technician.

4. Dry cord and unit.

5. Electrician must replace Power Cord with GFCI.

Motor does not

operate or

the Foot Switch sticks.

Pneumatic Foot Switch may have a leak.

Check for leaks in air line leading from Foot Switch.

Check for tears and holes in Foot Switch.

Replace if needed.

The Rotation Switch

does not work.

The centrifugal switch requires the

motor to come to a complete stop

before it will allow the direction

of the motor to be changed.

Move the Rotation Switch to the

OFF

position and allow the motor to stop before

changing from

FOr

to

rEV

or vice versa.