SKU 91500

PAGE 18

To Perform Free Arm Sewing (Tubular Work):

1.

This Sewing Machine can achieve tubular work by removing the Moveable Sew

ing Table (13A). This is especially convenient for finishing hard-to-reach areas

such as arm holes, overcasting trouser cuffs, etc. (See Figure D.)

9.

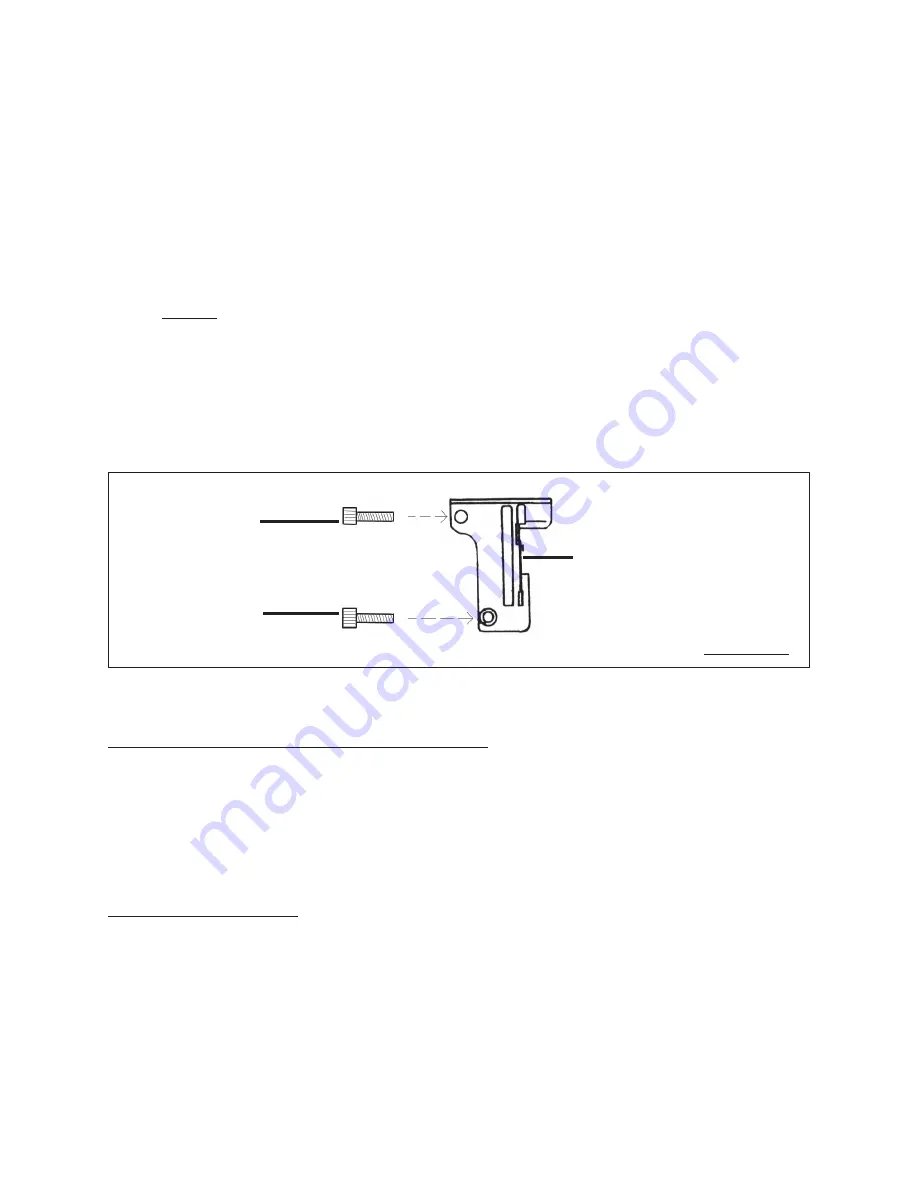

Install a Hem Needle Plate Assembly (2E - not included), and replace the two

Needle Plate Screws (5E, 6E). (See Figure D and Figure P.)

10.

Replace the Moveable Sewing Table (13A). (See Figure D.)

11.

For rolled hemming, adjust the seam width to the position of “M” on the Hem

Needle Plate (3E). Then align the left edge of the Lower Knife Bracket (27D)

with the “M” mark on the Hem Needle Plate. (See Figure M.)

12.

NOTE: Make sure the Lower Knife (28D) is not in contact with the edge of the

Hem Needle Plate (3E). When performing rolled-hem stitching, make sure to

adjust the thread tension correctly. At the start of sewing, slightly pull the end of

the chain off so it will not be entangled in the stitch.

(See Figure M and Figure P.)

HEM NEEDLE PLATE

(3E)

NEEDLE PLATE

SCREW

(5E)

FIGURE P

NEEDLE PLATE

SCREW

(6E)

To Perform Gathering:

1.

A single layer of light weight fabric can be gathered to achieve sleeve heads,

lower edges, yokes, leca edging, or frills. To do so, set the Feed Adjusting Knob

(21E) at its maximum “5”. Set the Differential Feed Adjusting Stud (93E) from

“1.5” to “2”. (See Figure D.)