Page 18

For technical questions, please call 1-888-866-5797.

56385

SAF

eT

y

O

Pe

RA

TiO

n

M

A

in

Ten

A

n

C

e

Se

Tu

P

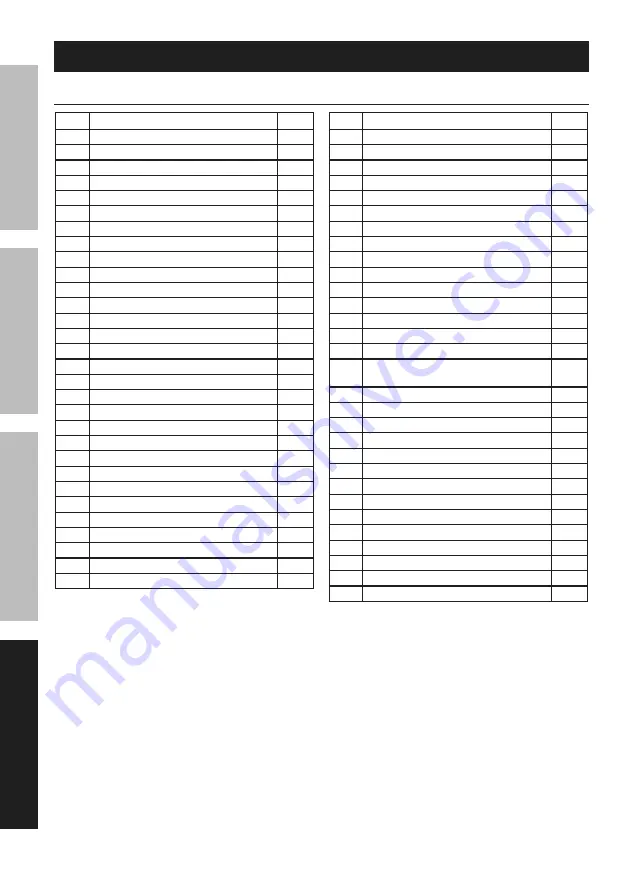

Parts List and Diagram

Parts List

Part

Description

Qty

1

Hex Socket Screw M6X20

10

2

Motor Cover

1

3

Hex Socket Screw M4 X 10

2

4

Motor Terminal Cover

1

5

Hex Socket Screw M8 x 25

4

6

Washer

4

7

Motor

1

8

Sliding Bearing

2

9

Seal

2

10 Drive Shaft

1

11 Brake

1

12 Hex Socket Pan Head Screw M6 x 20

4

13 Control Box Kit

1

14 Tie Bar

2

15 Drum

1

16 Lock Pin

4

17 Gear Box Base

1

18 Planetary Gear 3

1

19 Ring Gear

1

20 Washer

1

21 Planetary Gear 2

1

22 Radial Ring

1

23 Clutch Gear

1

24 Planetary Gear 1

1

25 O-Ring

1

26 Hex Socket Screw M5 x 20

4

27 Clutch Handle

1

28 Clutch Handle Washer

1

29 O-Ring

1

30 Tighten Screw

1

Part

Description

Qty

31 Seal

1

32 Gear Box End Cap

1

33 Gear Box Housing

1

34 Bearing

1

35 Sun Gear

1

36 Winch Mounting Hardware Kit

4

37 Hawse Fairlead

1

38 Hawse Fairlead Mounting Hardware Kit

2

39 Extended Terminal

3

40 Sheath

1

41 Hex Socket Pan Head Screw M6 x 12

4

42 Power Cable (relocation kit)

3

43 Terminal Box

1

44 Screw M4 x 12

2

45 Terminal Box Cover

1

46 Hex Socket Pan Head Self

Tapping Screw M5 x 16

3

47 Hex Socket Screw M8 x 18

1

48 Rope Retainer

1

49 Synthetic Rope

1

50 Power Switch

1

51 Base Plate Mounting Hardware

4

52 Base Plate

1

53 Control Box Mounting Hardware

4

54 Ground Cable

1

55 Power Cable (0.35M)

1

56 Power Cable (1.8M)

1

57 Handheld Switch Cable

1

58 Handheld Switch

1

59 Hand Strap

1

60 Hook

1