1 5

INSTALLATION INSTRUCTIONS CONT.

GAS CONNECTION CONT.

Where a flexible hose assembly is used, ensure it is approved to AS/NZS 1869, Class B. Any hose assembly

used must be restrained from accidental contact with the flue outlet of an under bench oven. This hose

assembly shall be suitable for connection to a fixed consumer piping outlet located as follows: Hotplates

at a point 800 mm to 850 mm above the floor and in the region outside the width of the appliance to a

distance of 250 mm.

After connecting to gas, check for leaks using soapy solution, never a naked flame.

GAS SPECIFICATION

Where a flexible hose assembly is used, ensure it is

approved to AS/NZS 1869, Class B. Any hose assembly

used must be restrained from accidental contact with

the flue outlet of an under bench oven.

This hose assembly shall be suitable for connection to a

fixed consumer piping outlet located as follows:

Hotplates at a point 800 mm to 850 mm above the floor

and in the region outside the width of the appliance to a

distance of 250 mm.

After connecting to gas, check for leaks using soapy

solution, never a naked flame.

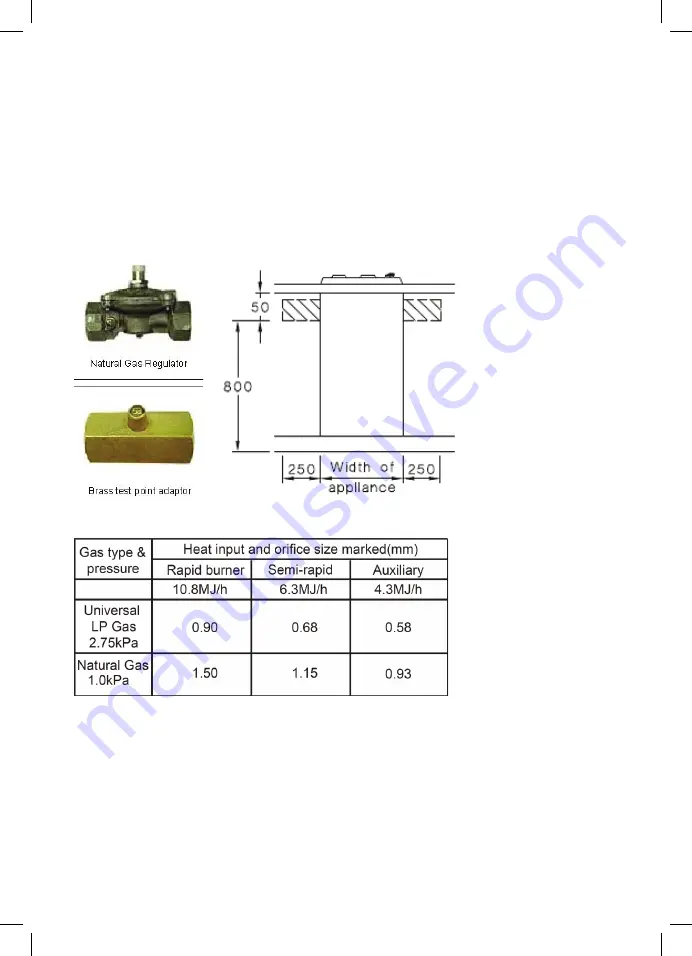

Inlet connection region for flexible hose

Gas Connection

Install in accordance with relevant gas standards and/or codes of

practice applicable.

Connect the elbow fitting to the appliance gas manifold

connection, and check that seals between the elbow and

manifold connection are in place and in good condition.

For Natural gas: connect the natural gas appliance

regulator (pictured opposite) with integral test point using

approved gas thread tape or compound to the elbow

fitting.

For Universal LPG: connect the brass test point adaptor

(pictured opposite) using approved gas thread tape or

compound to the elbow fitting.

Ensure the supply connection point, test point and natural gas

regulator adjustment screw (for Natural gas installation) are

accessible for testing and/or adjustment with the hotplate in

the installed position.

20

■

■

■

Flexible Hose: If installing with a hose assembly, it must comply with AS/NZS

accordance with AS/NZS 5601.1.

Ensure that the hose does not contact the hot surfaces of the

hotplate,oven,dishwasher or any other appliance that may be installed

underneath or next to the hotplate.The hose should not be subjected to abrasion,

kinking or permanent deformation and should be able to be inspected along its

entire length with the cooktop in the installed position. Unions compatible with

the hose fittings must be used and all connections tested for gas leaks.The

supply connection point shall be accessible with the appliance installed.

WARNING: Ensure that the hose assembly is restrained from accidental contact

with the flue outlet of an underbench oven.

Gas Connection

1869,10mmID,class B or D,no more than 1.2m long and installed in

Where a flexible hose assembly is used, ensure it is

approved to AS/NZS 1869, Class B. Any hose assembly

used must be restrained from accidental contact with

the flue outlet of an under bench oven.

This hose assembly shall be suitable for connection to a

fixed consumer piping outlet located as follows:

Hotplates at a point 800 mm to 850 mm above the floor

and in the region outside the width of the appliance to a

distance of 250 mm.

After connecting to gas, check for leaks using soapy

solution, never a naked flame.

Inlet connection region for flexible hose

Gas Connection

Install in accordance with relevant gas standards and/or codes of

practice applicable.

Connect the elbow fitting to the appliance gas manifold

connection, and check that seals between the elbow and

manifold connection are in place and in good condition.

For Natural gas: connect the natural gas appliance

regulator (pictured opposite) with integral test point using

approved gas thread tape or compound to the elbow

fitting.

For Universal LPG: connect the brass test point adaptor

(pictured opposite) using approved gas thread tape or

compound to the elbow fitting.

Ensure the supply connection point, test point and natural gas

regulator adjustment screw (for Natural gas installation) are

accessible for testing and/or adjustment with the hotplate in

the installed position.

20

■

■

■

Flexible Hose: If installing with a hose assembly, it must comply with AS/NZS

accordance with AS/NZS 5601.1.

Ensure that the hose does not contact the hot surfaces of the

hotplate,oven,dishwasher or any other appliance that may be installed

underneath or next to the hotplate.The hose should not be subjected to abrasion,

kinking or permanent deformation and should be able to be inspected along its

entire length with the cooktop in the installed position. Unions compatible with

the hose fittings must be used and all connections tested for gas leaks.The

supply connection point shall be accessible with the appliance installed.

WARNING: Ensure that the hose assembly is restrained from accidental contact

with the flue outlet of an underbench oven.

Gas Connection

1869,10mmID,class B or D,no more than 1.2m long and installed in