35

ALPHA

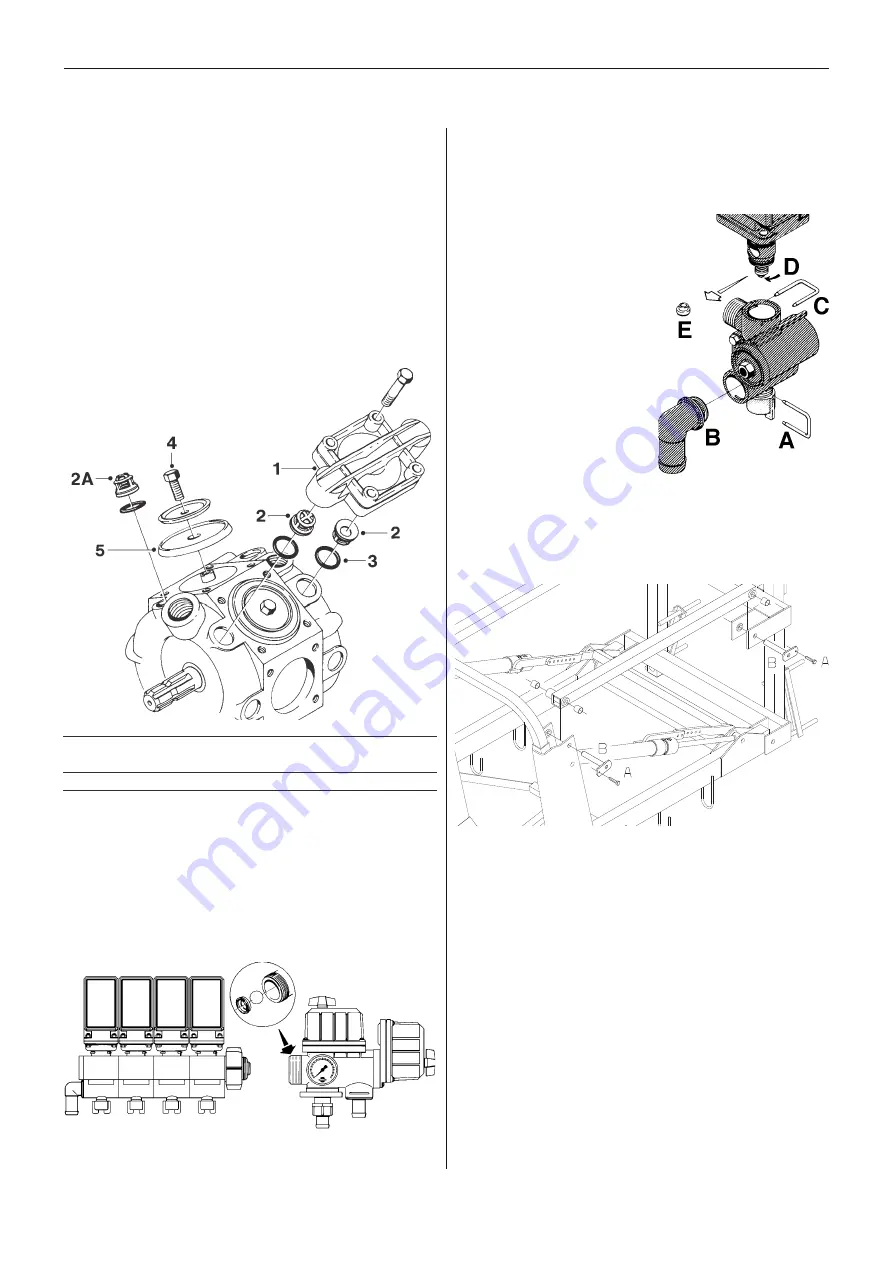

Cone check/renewal, EC distribution valve

Periodically check the distribution valves for proper seal-

ing. Do this by running the sprayer with clean water and

open ON/OFF valve and all distribution valves.

Cautiously remove the clip

A

and pull out the hose

B

for the pressure equaliza-

tion device. When the hous-

ing is drained, there should

be no liquid flow through

the pressure equalization

device. If there is any leak-

age, the valve cone

E

must

be changed.

Remove the clip

C

and lift

the EC-motor housing off

the valve housing. Then un-

screw the screw

D

and re-

place the valve cone

E

. Re-

assemble in opposite se-

quence.

Wear bush renewal, boom lift

The wear bushes are inspected and renewed before

they are worn through.

1. Unfold the booms to working position.

2. Lift the boom centre frame with a lifting device and

support it until the load is taken off the parallelogram

arms.

3. Remove the screws

A

, pull out the pins

B

at one of

the upper parallelogram arms, and renew the wear

bushes.

4. Refit the arm.

5. Repeat this on the other upper arm.

6. The lower arms must be disconnected simultane-

ously.

7. Grease all grease nipples.

8. Remove the lifting gear again.

Ball seat check/renewal, EC on/off valve

If the main ON/OFF valve does not seal properly (drip-

ping nozzles when main ON/OFF valve is closed), the

ball and seat should be checked.

Remove the 2 bolts fixing the main ON/OFF pressure

valve unit to the bracket, unscrew the union nut

A

and

pull the valve away from the distribution valves.

Pump valves and diaphragms renewal

Valves

Remove valve cover

1

. Before changing the valves

2

,

note their orientation so they are replaced correctly.

NOTE: One special valve with white flap

2A

is used. It

has to be placed in the valve opening shown.

It is recommended to use new gaskets

3

when changing

or checking the valves.

Diaphragms

Remove the diaphragm cover

4

. The diaphragm

5

may

then be changed. If fluids have reached the crankcase,

re-grease the pump thoroughly. Check also that the

drain hole at the bottom of the pump is not blocked. Re-

assemble with the following torque setting:

Pump

Diaphragm / valve cover

Diaphragm

Model

Nm

bolt Nm

462

90

80

1 Nm = 0.74 lbft

A

Check the ball for sharp edges and scratches and check

the ball seat for cracks and wear - replace if necessary.

Summary of Contents for ALPHA 2000

Page 5: ......

Page 6: ......

Page 7: ......

Page 9: ......

Page 16: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 51: ......

Page 52: ...52 ALPHA Notes...