23

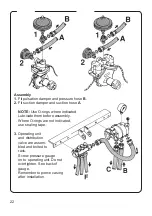

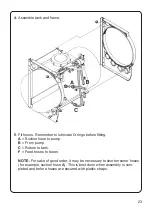

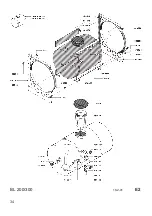

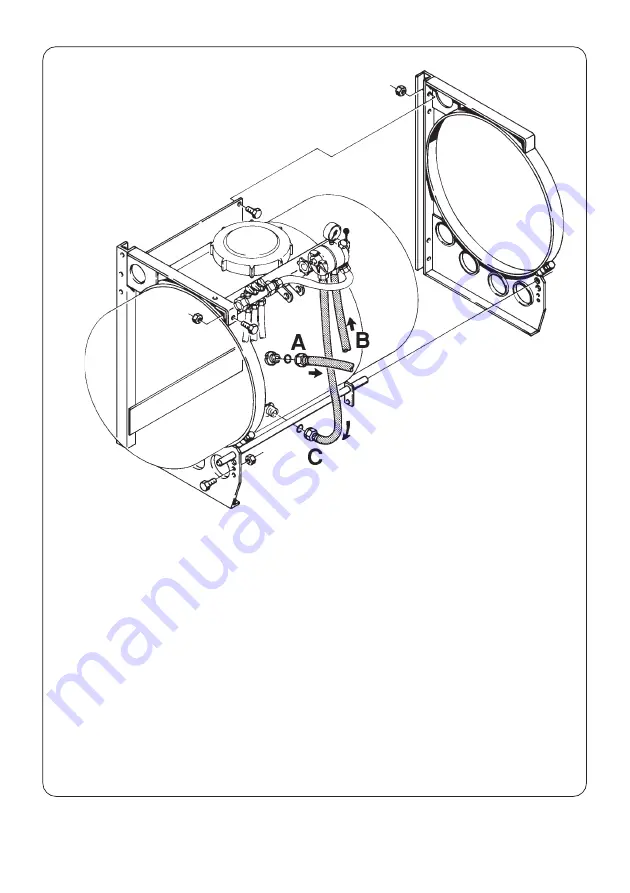

4. Assemble tank and frame.

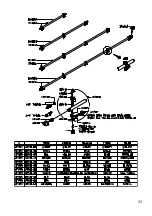

5. Fit hoses. Remember to lubricate O-rings before fitting.

A = Suction hose to pump.

B = From pump.

C = Return to tank.

F = Feed hoses to boom.

NOTE: For sake of good order, it may be necessary to shorten some hoses

(for example, suction hose A). This is best done when assembly is com-

pleted and before hoses are secured with plastic straps.

Summary of Contents for BL Series

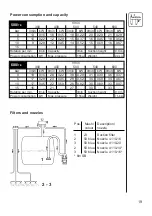

Page 11: ...11 1 X 40 2 X 20 3 X 40 4 X 40 11 6 10 10 8m SB T213 0010 T201 0002 ...

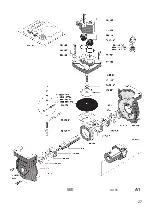

Page 27: ...27 500 4 9 95 A1 ...

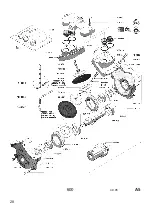

Page 28: ...28 600 4 9 95 A5 ...

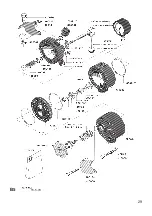

Page 29: ...29 B5 15 5 79 ...

Page 30: ...30 B6 18 2 91 ...

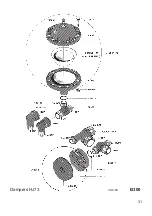

Page 31: ...31 Dampers HJ73 30 9 93 B300 ...

Page 32: ...32 SB 6 8 10m 18 2 91 D2 ...

Page 33: ...33 ...

Page 34: ...34 BL 200 300 18 2 91 E2 ...

Page 35: ...35 Notes ...

Page 36: ...36 Notes ...