5 - Operation

5.11

A

B

C

D

E

F

G

In order to close the entire boom, switch ON/OFF (3) to OFF posi-

tion. This returns the pump output to the tank through the return

system. The diaphragm Non-drip valves ensure instantaneous clo-

sing of all nozzles.

In order to close one or more sections of the boom, switch the rele-

vant distribution valve (7) to off position. The pressure equalisation

ensures that the pressure does not rise in the sections which are to

remain open.

On the sprayer the suction SmartValve should be turned toward

“Suction from Main tank” and pressure SmartValve should be turned

toward “Spraying”. Turn the agitation valve to “Agitation” if necessary.

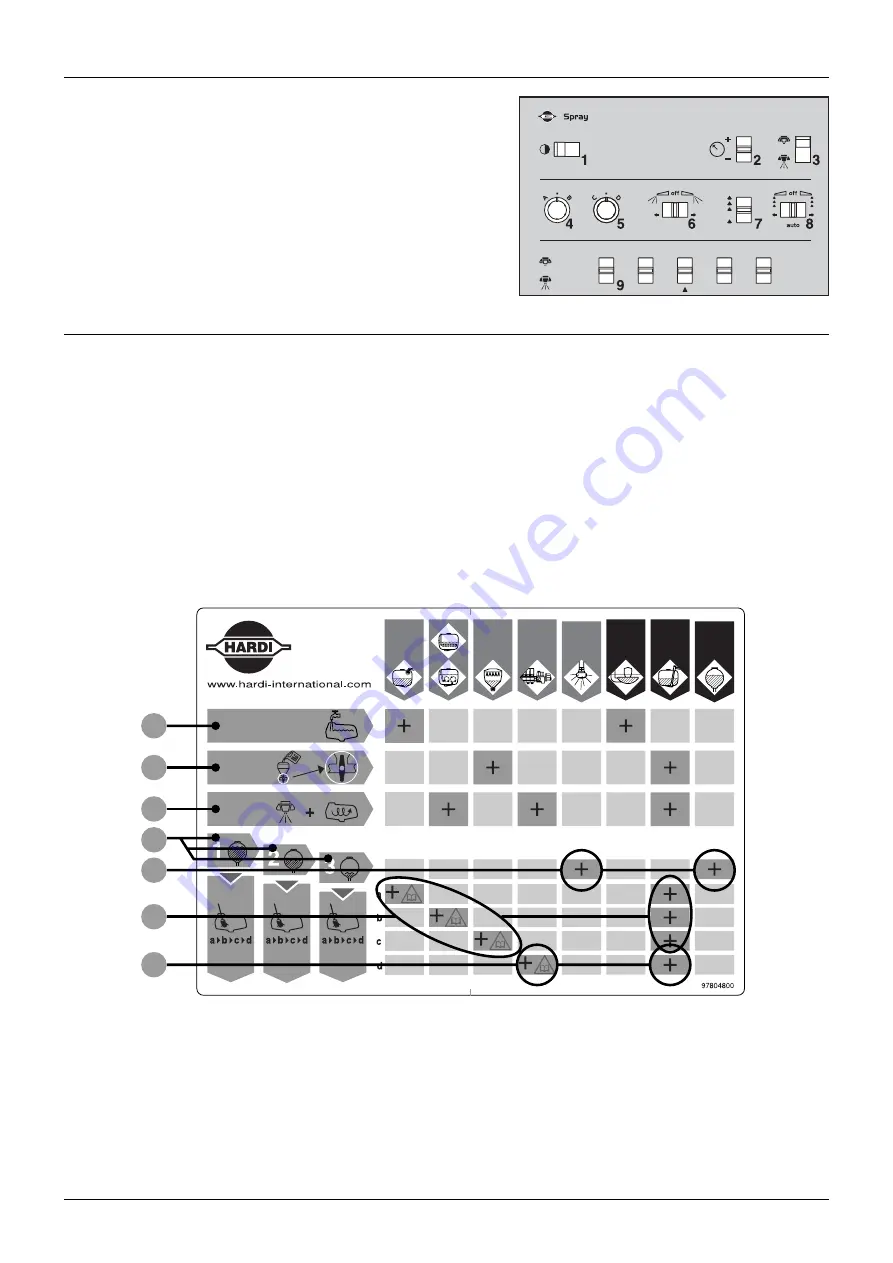

The Quick reference are to be “read” like the “+” signs designates the grip positions on the SmartValves for every use situa-

tions:

(A) designates “water filling into the main tank”.

(B) designates “filling chemicals by using HARDI FILLER”.

(C) designates “spraying in the field”.

Cleaning procedure (D) and should be repeated 3 times, by using 1/3 of rinsing tank content each time. Meanwhile aspi-

rating 1/3 of rinsing tank content, use grip positions (E). As a part of the cleaning procedure rinsing water must be flus-

hed through all functions (F), and is done in the steps (a), (b) and (c). (G) designates grip positions for the last step (d) in

the cleaning process where all the diluted tank content is sprayed out. Read more about correct cleaning procedures in

the subject “Cleaning”.

Quick reference