32

HARDI

®

COMMANDER OPERATOR’S MANUAL

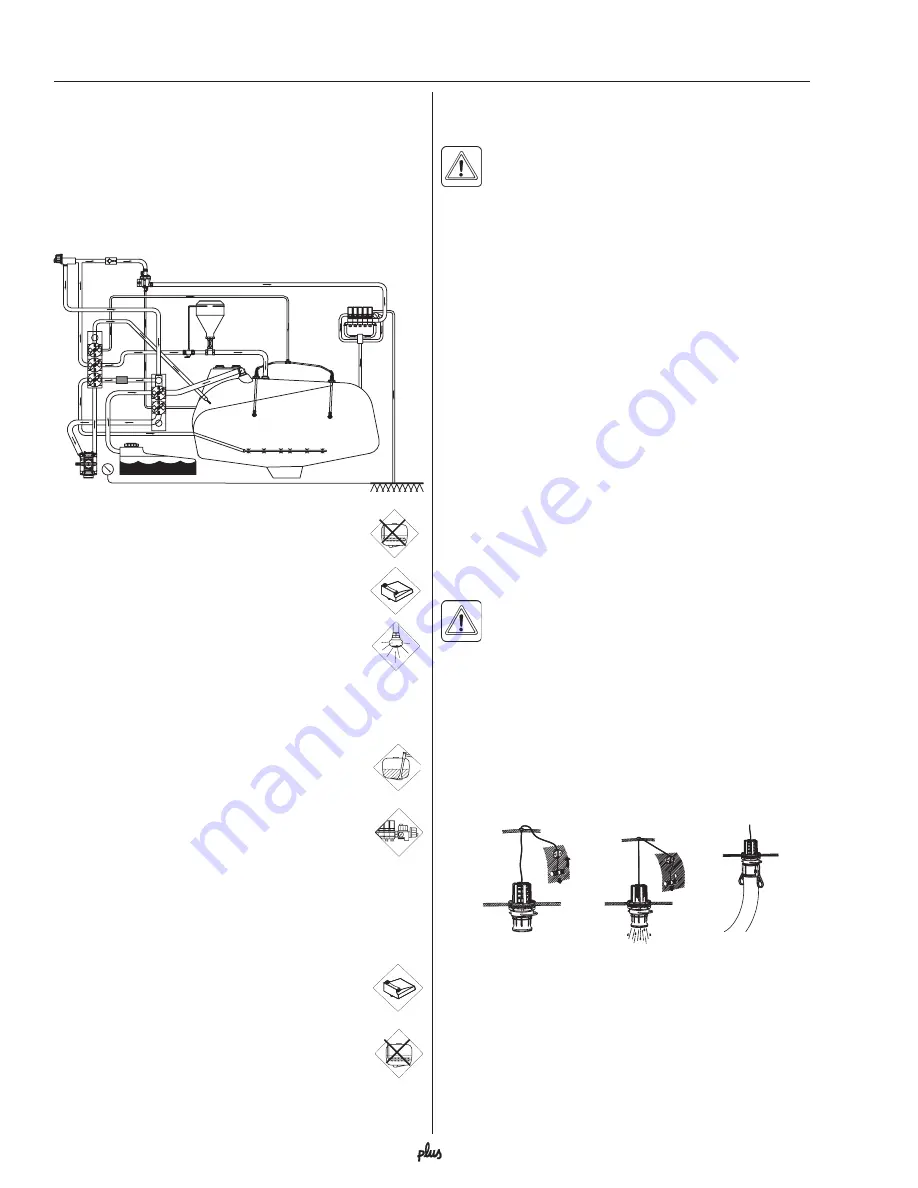

Use of flush tank and rinse nozzles

(optional)

The incorporated flush tank can be used for two differ-

ent purposes.

A

. In-field diluting of remaining spray liquid residue in

the spraying circuit for spraying the liquid in the field,

before cleaning the sprayer.

1. Empty the sprayer as much as possible.

Turn the green pressure valve towards “No

Agitation” and spray until air comes out of

all nozzles.

2. Remove the tank filter basket.

3. Turn black suction valve towards “Flush

tank”.

4. Turn green pressure valves towards “Rins-

ing nozzle” (optional).

5. Engage and set the pump at approx. 300

r.p.m.

6. When rinsing water corresponding to approx. 10

times the spray liquid residue (see paragraph

“Technical Residue”) is used, turn black

suction valve towards “Suction from main

tank” and operate all valves, so all hoses

and components are rinsed.

7. Turn green pressure valve back to “Operat-

ing unit” and spray liquid in the field you

have just sprayed.

8. Repeat point 3-7 until the flush tank is empty.

B

. Rinsing the pump, operating unit, spray lines, etc. in

case of interruption in spraying before main tank is

empty (e.g. due to rain, etc.).

1. Close Self-cleaning filter (yellow valve).

2. Turn black suction valve towards “Flush

tank”.

3. Turn green pressure valve towards “No

Agitation”

4. Engage the pump and spray water from

rinsing tank in the field until all nozzle tubes/nozzles

are flushed with clean water.

Operation

5. Disengage pump again.

6. Open Self-cleaning filter again.

WARNING!

The rinsing nozzles cannot always

guarantee a 100% cleaning of the tank. Always

clean manually with a brush afterwards, espe-

cially if crops sensitive to the chemical just sprayed are

going to be sprayed afterwards!

Technical Residue

Inevitably a quantity of spray liquid will remain in the

system. It cannot be sprayed properly on the crop, as the

pump takes in air when the tank is about to be empty.

This Technical Residue is defined as the remaining

liquid qty. in the system as the first clear pressure drop

on the pressure gauge is read.

The dilutable residue must be diluted with 10 times the

amount of clean water and sprayed to the crop just

sprayed before cleaning the sprayer - See “Cleaning

the sprayer” (pp. 36-37).

Draining tanks

Operation of the main tank drain valve

WARNING!

Before using the top drain, verify that

disposal of waste is done according to chemical

label instructions and local regulations.

Pull the red handle at left hand side of the tank to open

the drain valve. The valve is spring loaded to close it,

but can be kept open by pulling the string out and

upwards in the V-shaped slot. To release and close the

drain valve again, pull the string downwards and the

valve will close automatically. If draining residues (e.g.

liquid fertilizer) into a reservoir, a snap-coupler with

hose can rapidly be connected to the drain valve and

the liquid safely drained.

Flush tank (optional)

To avoid algae developing in the flush tank, always

drain the flush tank when the sprayer is not in use for a

long period.

Foam marker tank (optional)

If the sprayer is to stand a few days, it is recommended

to drain and flush the foam marker tank to avoid mixed

foam from becoming inactive, as once mixed, foam

deteriorates rapidly.