49

HARDI

®

COMMANDER OPERATOR’S MANUAL

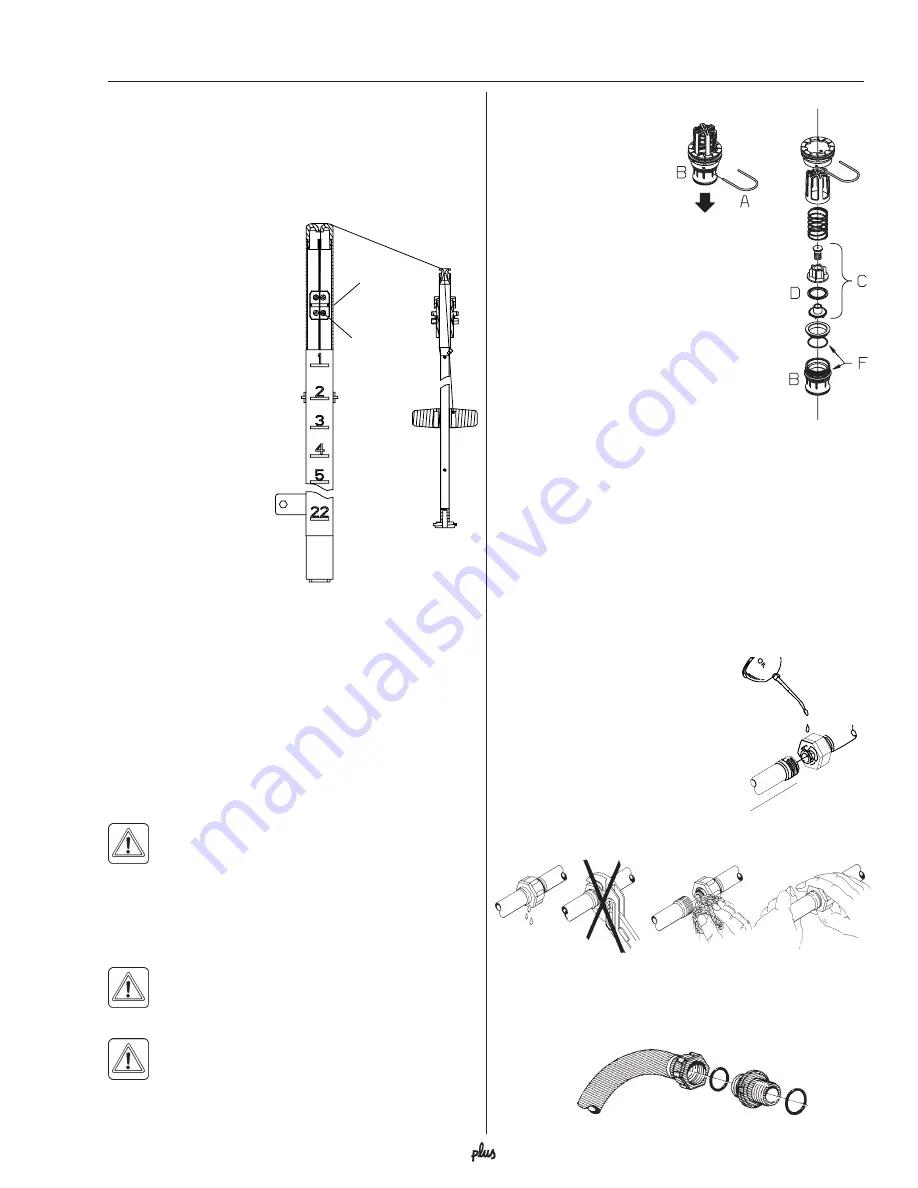

Shock absorbers

If the shock absorbers loose their efficiency or start

leaking oil, they should be replaced.

Level indicator adjustment

The level indicator reading should be checked regularly.

When the tank is empty,

the float should lie on the

stop pin, of the rod, and

the O-ring on the indicator

should be positioned at

the top position line

A

.

If any deviation is found,

pull out the plug

B

, loosen

screws

C

, and adjust the

length of the cord.

Cord renewal, level indicator

If the cord on the level indicator has to be changed, the

float guide pole is removed:

1. Remove the tank drain valve (see paragraph “Main

tank drain valve”) and loosen the fitting holding the

pole in position.

2. Pull the pole down through the drain valve hole till it

is free in the top of the tank.

3. The pole can now be taken out of the tank through

the filling hole.

DANGER!

Do not attempt to enter the tank - the

float pole can be removed from outside the tank!

Seal replacement, drain valve

If the main tank drain valve leaks, the seal and seat

can be changed the following way.

DANGER!

Do not enter the inside of the tank -

the parts can be changed from underneath the

tank!

WARNING!

Use eye / face protection mask

when dismantling the tank drain valve!

1. Make sure the tank is empty and clean.

2. The valve must be closed and the string loose.

Maintenance

A

C

B

3. Pull out the clip

A

and

pull down connecting

piece

B

. The entire

valve assembly can

now be pulled out.

4. Check cord and valve

flap assembly

C

for

wear, replace seal

D

and assemble again.

5. Assemble the valve

assembly again using

a new valve seat

E

.

Lubricate O-rings

F

before assembly.

6. Fit clip

A

again.

NOTE! Check the function of the valve

with clean water before filling chemicals

into the tank.

Nozzle tubes and fittings

Poor seals are usually caused by:

- missing O-rings or gaskets

- damaged or incorrectly seated O-rings

- dry or deformed O-rings or gaskets

- foreign bodies

In case of leaks:

DO NOT overtighten

. Disas-

semble, check condition and

position of O-ring or gasket.

Clean, lubricate and reassemble.

The O-ring must be lubricated

ALL THE WAY ROUND

before

fitting on to the nozzle tube. Use non-mineral lubricant.

For

RADIAL

connections only hand-tighten them.

For

AXIAL

connections, a little mechanical leverage

may be used.