44

HARDI

®

COMMANDER OPERATOR’S MANUAL

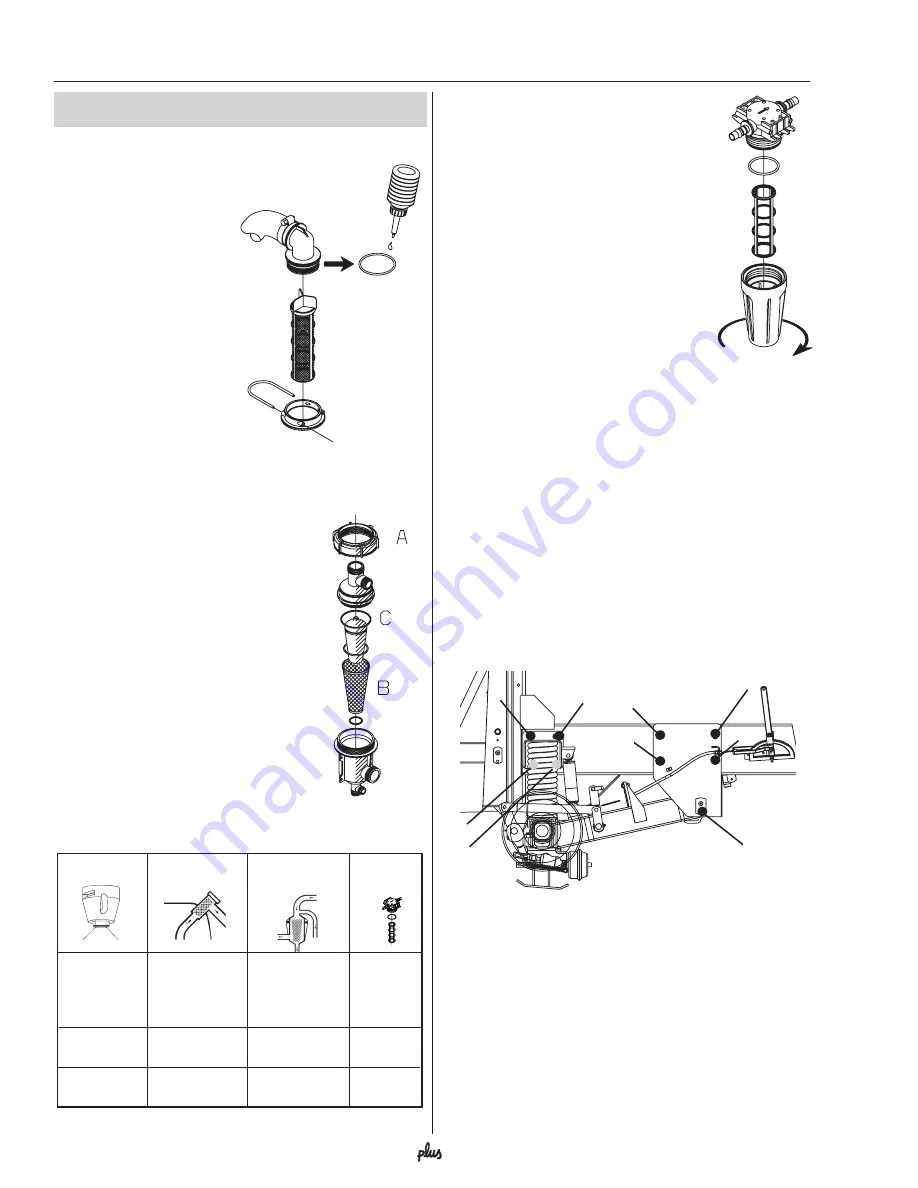

3. In-Line filter

Unscrew the filter bowl to inspect and

clean the filter.

Alternative filters are available. See

section on Technical specifications -

Filters and nozzles.

4. Spraying circuit

Fill with clean water, operate all functions and check for

leaks using higher spray pressure than normal. Check

nozzle spray patterns visually using clean water.

5. Retighten bolts (suspension only)

Check that these 9 bolts - on each side of the COM-

MANDER Plus - are tight. Retighten if necessary.

Tightening torque:

Bolt

1 = 18 Ft/lb (24 Nm)

(secure nut on the backside of

the mounting with a wrench

while adjusting bolt 1).

Bolt

2-9: 207 Ft/lb (280 Nm)

Bolt 8 and 9 are situated behind the spring.

10 hours service

1. Suction filter

To service the suction filter:

1. Pull out the steel clip

A

.

2. Lift the suction hose

fitting

B

from housing.

3. Filter guide and filter

C

can now be removed.

To reassemble:

4. Press the guide onto

filter end.

5. Place the filter into

housing with guide

facing up.

6. Ensure the O-ring

D

on the hose fitting is in

good condition and

lubricated.

7. Refit the suction hose

B

and steel clip

A

.

2. Self-Cleaning Filter

1. Unscrew nut

A

and open filter.

2. Check filter gauze

B

, clean if

necessary

3. Lubricate O-ring

C

4. Assemble filter again.

Maintenance

A

B

C

D

7

6

4

3

5

2

1

8

9

*

Standard Equipment

50

100

Suction Filter

Nozzle Size

Self Cleaning

Filter

50

30*

Red (04)

& Larger

80*

50

Lilac (25)

Blue (03)

Pink (0075)

Orange (01)

Green (015)

Yellow (02)

FILTER SIZE SELECTION TABLE

Inline

Filter

100

80

50*