4 - Sprayer setup

4.17

ATTENTION! To ensure safe engagement and to avoid dama-

ges to the parking brake use rope with an ultimate stress bet-

ween 690 N (155 lb.) and 785 N (176 lb.).

WARNING! Do not connect the brakes directly to the tractor

hydraulics without the brake valve. The trailer brake power

cannot be controlled, and braking will therefore be hazar-

dous.

WARNING! Max. oil pressure is 150 bar (2175 p.s.i.) in the brake

line.

Relieve parking brake before driving.

The parking brake is located at the right side of the sprayer in the

clean zone.

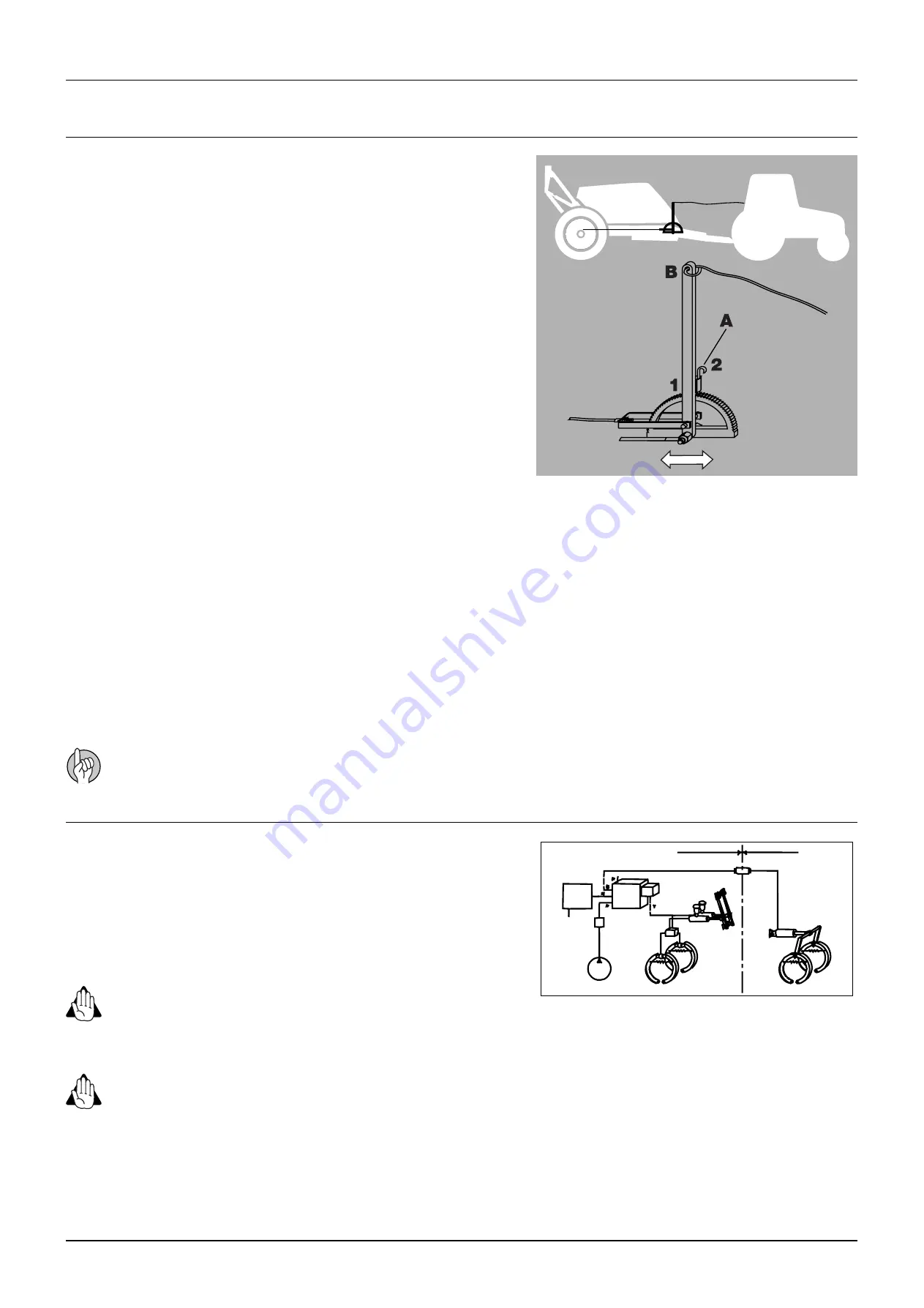

The parking brake lever has two function modes, which are determi-

ned by the small pawl control clip (A). To change between the two

modes, turn the clip.

Pos. 1: The pawl control clip must rest against the pawl.

Pos. 2: The pawl control clip must point away from the pawl.

To disengage the parking brake:

1. Set pawl control clip in pos. 1.

2. Pull the lever a little forward to release the pawl from the ratchet

and then push the lever fully backwards.

To engage the parking brake:

1. Set pawl control clip in pos. 2.

2. Pull the lever firmly forwards until parking brake is fully engaged.

Emergency brake

1. Set pawl clip in pos. 2.

2. Attach the rope from the hole in top of the handbrake lever (B) to

e.g. the tractor top link attaching point. If the sprayer is accidentally

unhooked during transport the rope will apply the parking brake

before the rope breaks.

This requires a special trailer brake valve attached to the tractor hyd-

raulic and brake system. Connect the snap coupler to the tractor

brake outlet. When the tractor brakes are applied, the trailer brakes

will work proportionally to the tractor brakes, and ensure safe and

effective braking.

Hydraulic activated brakes (optional equipment)

Emergency and parking brake (optional equipment)

Brakes

Summary of Contents for COMMANDER TWIN FORCE 3200

Page 8: ...Table of contents TOC 6 ...

Page 10: ...1 CE Declaration 1 2 ...

Page 14: ...2 Safety notes 2 4 ...

Page 66: ...6 Maintenance 6 2 Boom lubrication oiling plan 32 36 m ...

Page 67: ...6 Maintenance 6 3 Trailer lubrication oiling plan ...

Page 107: ...8 Technical specifications 8 11 Charts Boom hydraulic Y Boom hydraulic Z ...

Page 108: ...8 Technical specifications 8 12 Sprayer hydraulic Fan transmission ...

Page 109: ...8 Technical specifications 8 13 Electrical specifications for boom and work light ...

Page 110: ...8 Technical specifications 8 14 ...