6 - Maintenance

6.9

WARNING! Always prime the circuit if the hydraulic brake lines have been dismantled.

Apply brakes to full pressure and inspect brake lines for damages or leaks. Replace damaged parts. If the hydraulic brake

lines have been dismantled the circuit must be primed afterwards:

1. Loosen brake hose at both brake cylinders.

2. Apply brake until oil without air bubbles come out.

3. Tighten brake hose before relieving the brake again.

Change the protection tube nylon bearings as described under “Shield renewal on transmission shaft”.

Change the hydraulic oil filter after the first 50 hours and then every

500 hours or once a year - whichever comes first.

Always change the oil filter if the vacummeter indicator is in the red

area. Check when the oil has reached working temperature.

1. Place e.g. a drain pan or a cloth under the filter to retain waste oil

and unscrew the filter cartridge.

2. The new filter cartridge is filled with fresh clean hydraulic oil.

Apply a thin oil film to the cartridge seal.

3. Screw the filter cartridge on until the seal is lying against the flan-

ge.

4. Tighten the filter cartridge another 1/2 to 3/4 turn.

5. Check hydraulic oil level - top up with fresh clean hydraulic oil if

necessary.

6. Set the blower in neutral, start the tractor P.T.O. and let it run idle

for 5 min. to prime the sysstem.

7. After 5 min. the blower r.p.m. can gradually be increased to full

speed.

Disposal of used hydraulic filter cartridges must only take place in

accordance with local legislation.

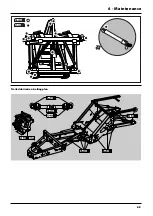

1000 hours service - Transmission shaft

500 hours service - Hydraulic oil filter

250 hours service - Hydraulic brakes

Summary of Contents for COMMANDER TWIN FORCE 3200

Page 8: ...Table of contents TOC 6 ...

Page 10: ...1 CE Declaration 1 2 ...

Page 14: ...2 Safety notes 2 4 ...

Page 66: ...6 Maintenance 6 2 Boom lubrication oiling plan 32 36 m ...

Page 67: ...6 Maintenance 6 3 Trailer lubrication oiling plan ...

Page 107: ...8 Technical specifications 8 11 Charts Boom hydraulic Y Boom hydraulic Z ...

Page 108: ...8 Technical specifications 8 12 Sprayer hydraulic Fan transmission ...

Page 109: ...8 Technical specifications 8 13 Electrical specifications for boom and work light ...

Page 110: ...8 Technical specifications 8 14 ...